Extracting olive oil is an art form, a breathtaking race against time. It’s the craft of capturing a perfect, fleeting moment from the sun-drenched grove and sealing it in a bottle. In this high-stakes game, timing, temperature, and technique are the three pillars that divide a forgettable oil from one that sings on the palate. Those first few hours between the olive leaving the branch and the press beginning its work… they are, quite simply, everything.

The Art and Soul of Olive Oil Extraction

Before we talk presses and centrifuges, you must understand the soul of the process. Think of an olive as a tiny, perishable vessel, brimming with flavor and health. The very second it is plucked from the tree, its peak quality is in the past. The entire goal of extraction, then, isn’t to add anything, but to lose as little as possible of the miracle nature has already perfected.

This is where the transformation happens. Turning a solid fruit into liquid gold is a delicate, urgent dance. It's a dead sprint to lock in the olive’s vibrant, peppery notes and potent antioxidants before they vanish into thin air. Every decision from this point forward will echo in the final taste and aroma of the oil.

The Unspoken Truth of Freshness

The greatest producers I’ve ever met all share a secret that defines their craft: the clock starts ticking the second an olive leaves its branch. This is not poetry; it is hard, unforgiving chemistry.

“One of the keys to quality is getting the olives from the tree down to the mill as quickly as possible… We’re able to mill within hours of picking the fruit. Once you pick the fruit, it’s not gonna be better. Olive oil is not like wine. It doesn’t improve with age.”

This immediate processing is non-negotiable for anyone aspiring to create a world-class extra virgin olive oil. Delays invite oxidation and fermentation—the sworn enemies of freshness—which spawn those dreaded "off" flavors of mustiness or rancidity. A delay of even 24 hours can be the fatal blow that separates an award-winning oil from one destined for the refinery.

What We Are Really Extracting

When we speak of extracting olive oil, we’re doing more than just squeezing out fat. The true prize is the symphony of compounds that makes extra virgin olive oil a culinary and wellness marvel. The origin of olive oil is a rich and fascinating story, a testament to this timeless pursuit of quality.

Our primary goals are to:

- Preserve Polyphenols: These are the powerful antioxidants that deliver a great oil’s peppery kick and bitter finish—the very signature of its health benefits.

- Capture Volatile Aromas: The fresh, grassy, or fruity scents are incredibly delicate. The wrong technique or a whisper of excess heat, and they’re gone forever.

- Maintain Low Acidity: The level of free fatty acids is a key marker of quality. Swift, immaculate processing is the only path to keeping these levels exceptionally low.

Ultimately, extracting olive oil is less about industrial production and more about careful stewardship. It’s about honoring the fruit and capturing its essence at its absolute peak.

Harvesting and Preparing Your Olives

The journey to an unforgettable olive oil doesn't begin with the hum of machinery. It starts under an open sky, in the quiet grove, where every choice directly translates into the character of the oil. This is the moment quality is either captured or lost forever.

The first major decision is how you get the olives off the tree. This choice pits timeless tradition against modern efficiency, and each path leaves its distinct signature on the final product. It's a fundamental fork in the road for anyone serious about extracting olive oil.

The Great Harvest Debate

Hand-picking is the romantic ideal, a meticulous and gentle process where olives are carefully selected and plucked one by one. It's slow, back-breaking work, but its advocates swear by the results. By avoiding the bruising and damage that mechanical harvesters can cause, you protect the olive's delicate cellular structure and keep oxidation at bay.

On the other side of the coin, you have mechanical harvesters—powerful machines that shake the trees, causing ripe olives to rain down onto nets. They are incredibly efficient, capable of clearing an entire grove in a fraction of the time. This speed is their greatest advantage, as it dramatically shortens the crucial window between picking and milling.

A swift harvest means less time for the olives to sit and degrade, which is a massive win for maintaining low acidity and preserving freshness. The trade-off is the potential for more bruising if the equipment isn't operated with a skilled hand.

So, what's the right choice? It’s a classic battle between precision and pace.

- Hand-Harvesting: This is the go-to for smaller, artisanal producers aiming for an ultra-premium oil. It minimizes fruit damage and allows for selective picking, ensuring only the perfectly ripe olives make the cut.

- Mechanical Harvesting: This is the workhorse of most modern operations. When done correctly, it lets producers harvest vast quantities of olives at their peak and rush them to the mill within hours—a critical factor for quality.

Ultimately, the best method really depends on the scale of your operation and the style of oil you're after. You can get into the finer details of these techniques in our complete guide to olive oil harvesting.

The Crucial Cleaning Phase

Once your olives are collected, the race isn't over. Before they can ever be crushed, they must be perfectly clean. This step sounds simple, but it’s absolutely non-negotiable if you want to prevent defects in your oil.

Leaves, twigs, dirt, and other debris—what we sometimes call MOG (Material Other than Grapes, a term borrowed from winemaking)—can impart musty, earthy, or woody off-flavors. Leaves, in particular, are notorious for making the oil excessively bitter and grassy.

The cleaning process usually involves two main stages. First, the olives are passed through a de-leafer, a machine that uses a powerful fan to blow away the lighter leaves and twigs. Then, they’re given a quick but thorough wash in clean, cold water to remove any lingering field dust or soil. The key is to be effective without being aggressive; you want to clean the fruit, not beat it up.

Of course, a healthy grove is easier to harvest from in the first place. To ensure a bountiful and healthy harvest, understanding and implementing effective pest management is crucial; consider organic aphid control strategies to protect your olive trees naturally. This diligence in the grove pays dividends when it's time to clean the fruit.

This meticulous preparation is the final act of stewardship before the olives meet the mill. By delivering clean, healthy, and undamaged fruit, you have set the stage for a truly remarkable extraction.

Crushing and Malaxing the Olive Paste

This is where the true alchemy begins. Your carefully harvested and cleaned olives are about to be transformed from solid fruit into liquid gold. These next two steps—crushing and the subsequent mixing, or malaxing—are the very heart of extraction. Here, the oil’s final character is forged.

It sounds simple enough. Just break open the fruit to release the oil. But the method you choose has a staggering impact on everything from the oil's peppery bite to its delicate aromas. This is not about brute force; it is a delicate dance of cellular chemistry.

Releasing the Oil From the Olive

To get to that precious oil, you must first rupture the vacuoles—the tiny sacs inside the olive's cells where the oil is stored. The goal is a thick, uniform paste of skin, pulp, pit, and oil. Two schools of thought, and two very different machines, dominate this craft.

First, the traditional granite stone mill. If you've ever seen a picture of old-world olive oil production, this is it: massive, slowly turning stone wheels grinding the olives in a stone basin. It is a gentle, almost meditative process that crushes the fruit with less heat and oxidation. Artisans swear by it, believing it produces a sweeter, more delicate oil.

The modern method is the hammer mill. This machine is pure efficiency. It uses metal blades spinning at blinding speed to shatter the olives against a screen. It’s fast and gives the producer immense control, but it can also introduce more heat and oxygen if not managed with an expert hand. A hammer mill typically produces an oil with more robust, peppery, and bitter notes—the very qualities prized in today’s high-polyphenol oils.

The Art of Malaxing

After crushing, you're left with a thick, wonderfully fragrant olive paste. But the oil is still trapped in minuscule droplets, too small to separate. This brings us to malaxation, a step that looks like simple stirring but is actually a masterclass in patience and precision.

The paste is moved into a trough where slowly turning paddles gently fold it over and over. This is not aggressive blending; it is an act of coaxing. The slow, continuous motion encourages the tiny oil droplets to collide, merge, and form larger drops that can finally be extracted.

This gentle mixing is where the oil’s full aromatic potential awakens. Enzymes released during crushing begin creating the complex compounds that give extra virgin olive oil its signature notes of grass, fruit, or artichoke.

The entire process usually takes between 20 to 45 minutes. Cut it short, and you sacrifice yield, leaving precious oil behind. Let it go too long, and you risk over-exposing the paste to air, leading to oxidation and a flat, greasy-tasting oil. It’s a fine line that only experience teaches you how to walk.

Why Temperature Is Everything

Now we arrive at one of the most critical—and misunderstood—aspects of making great olive oil: temperature. The term "cold-pressed" is a direct promise about the heat level during malaxation. To earn that label, the temperature of the olive paste must never exceed 27°C (80.6°F).

Why so strict? Because heat is the assassin of quality. A little warmth might make the oil flow easier and increase your yield, but the cost is devastating. Heat destroys the delicate aromas and the precious polyphenols that give the oil its flavor, stability, and health benefits. Discover the full story on this critical distinction in our article explaining what is cold-pressed olive oil really means.

Any serious producer knows that sacrificing a little quantity to protect the quality is always the right call. The best mills use water-jacketed malaxers for precise temperature control, ensuring the soul of the olive is preserved, not boiled away.

This commitment to quality echoes across the globe. Spain, the titan of the industry, leads with approximately 1.41 million tons, about 40% of the world's output. The European Union's production saw a major rebound in the 2024/25 season, hitting roughly 2.1 million tons—a 40% increase from the prior season, with Spain, Greece, and Portugal leading the charge.

By mastering the crush and the malax, we’ve created a paste where the oil is primed for separation, its flavors fully awakened, and its quality fiercely protected. Now, it is time to liberate that liquid gold.

Separating Oil with a Press or Centrifuge

The olive paste is ready, fragrant with the promise of liquid gold. Now comes the moment of truth: the great separation where oil, water, and solids finally part ways. This is where two worlds collide—the patient, methodical art of the traditional press and the relentless, scientific efficiency of the modern centrifuge.

Each method is a philosophy, a choice that shapes the final character of the oil in your bottle. One whispers of history and nuance, while the other speaks of precision and purity. Understanding both is key to appreciating the craft of extracting olive oil.

The Old World Charm of the Hydraulic Press

Picture the classic image of olive oil production: stacks of round, woven mats glistening with olive paste, being slowly squeezed under immense pressure. This is the traditional hydraulic press in action. It’s a beautifully simple, almost romantic process that has been used for centuries.

The olive paste is spread evenly onto fiber disks, called fiscoli, which are then stacked. A hydraulic piston applies slow, steady pressure, gently weeping the oil and vegetable water from the paste. The liquid trickles down, collected in a basin below.

Proponents of this method believe it yields a sweeter, more delicate oil. Because the process is slower and exposes the paste to more oxygen, it can mellow out some of the harsher bitter notes, resulting in a rounder, softer flavor profile.

However, this old-world charm has its drawbacks. The fiber mats are notoriously difficult to clean perfectly, which can introduce defects if not managed with obsessive care. The prolonged exposure to air can also lead to oxidation, potentially shortening the oil's shelf life. For these reasons, true pressing is a rare art form today, practiced by only a handful of artisans dedicated to preserving a specific style.

The Modern Engine of Quality: A Centrifuge

Step into any modern mill, and you won't find stacks of mats. Instead, you'll hear the hum of a stainless-steel decanter centrifuge—the undisputed engine of the global olive oil industry. This machine is a marvel of physics, using incredible g-force to achieve in seconds what a press takes hours to do.

The olive paste is pumped into a horizontal bowl spinning at thousands of RPMs. The intense force instantly separates the components by their density: the heavy solid pulp (pomace) is flung to the outer wall, the lighter water forms a middle layer, and the lightest of all, the pure oil, collects in the center.

This continuous, enclosed system is exceptionally clean and minimizes contact with oxygen, fiercely protecting the oil’s delicate aromas and potent polyphenols. Nearly all of the world's elite extra virgin olive oils are born from this technology. You can explore more about the entire modern olive oil manufacturing process in our detailed guide.

Within the world of centrifuges, there are two main types to know:

- Three-Phase Centrifuge: This system cleanly separates all three components—oil, water, and solids—into distinct streams. The catch is that it requires adding warm water to work, which can unfortunately wash away some of the water-soluble polyphenols.

- Two-Phase Centrifuge: Widely considered the superior method for quality, this machine separates the oil from a wet paste containing both water and solids. It requires no added water, preserving the maximum amount of antioxidants and flavor.

The global reliance on this technology is staggering. The European Commission’s 2024/25 forecast predicts global olive oil production will hit 3.39 million metric tons. Spain alone is projected to produce 1.29 million tons, a massive 51% increase from the prior season, with the vast majority extracted using high-tech centrifuges.

Extraction Method Comparison: Press vs. Centrifuge

Choosing between a press and a centrifuge isn't just a technical decision; it's a choice that defines the final product's style, quality, and consistency. Here’s a side-by-side look at what sets them apart.

| Attribute | Traditional Hydraulic Press | Modern Decanter Centrifuge |

|---|---|---|

| Process Type | Batch process, slow and discontinuous | Continuous, automated process |

| Oxygen Exposure | High, due to open system and fiber mats | Minimal, enclosed system protects from air |

| Hygiene | Difficult; mats are hard to clean thoroughly | Excellent; stainless steel is easy to sanitize |

| Flavor Profile | Often produces softer, rounder, sweeter oils | Tends to create more vibrant, pungent, "green" oils |

| Polyphenols | Lower levels due to oxidation and process | Higher preservation of antioxidants and polyphenols |

| Water Usage | None required for separation | Three-phase needs added water; two-phase does not |

| Throughput | Low, labor-intensive | High, very efficient for large volumes |

| Common Use | Niche, artisanal production for a specific style | The global standard for high-quality EVOO |

Ultimately, while the press holds a special place in history, the centrifuge has become the gold standard for producing the clean, vibrant, and antioxidant-rich extra virgin olive oil prized by connoisseurs and health experts today.

Filtering and Storing Your Liquid Gold

You’ve made it. Through the harvest, the mill, and the great separation. The air is thick with the incredible aroma of fresh oil. But don't celebrate just yet. Getting the oil out is one thing; keeping it perfect is another battle entirely.

That freshly extracted oil is likely a bit cloudy. This is olio nuovo (new oil), and while its intense, rustic flavor is beloved by many, it's living on borrowed time. That beautiful cloudiness is a ticking clock—a suspension of tiny olive fruit particles and microscopic water droplets.

The Great Filtration Debate

So, do you filter it? This is a fiery debate among producers. Some argue that unfiltered oil has more character. They aren't wrong, but they are playing a dangerous game with the oil's longevity.

Here's the problem: those suspended solids and water don't remain suspended. Over time, they sink, forming a sediment. That sediment begins to ferment and decompose, spoiling the oil from the bottom up and creating profoundly unpleasant, muddy flavors.

Filtration is not an act of stripping character; it is an act of preservation. By passing the oil through a simple filter like cotton wadding, you remove these volatile elements. The result is a brilliantly clear oil that is far more stable, ensuring its vibrant flavor can be enjoyed for 18-24 months, not just a few weeks.

Think of filtration as buying time. You’re removing the very elements that will inevitably betray the oil's freshness, locking in the quality you worked so hard to create.

For anyone serious about making olive oil that lasts, filtration isn't an optional final touch. It’s a mandatory step for quality and longevity. Once the oil is filtered, understanding proper long-term food storage methods is the next critical piece of the puzzle to protect your liquid gold.

The Three Mortal Enemies of Olive Oil

Once your oil is filtered, it is stable, but not invincible. It now faces three relentless enemies that will stop at nothing to destroy its flavor, aroma, and health benefits.

Your primary foes are:

- Oxygen: This is enemy number one. Oxidation begins the moment oil meets air, causing rancidity. It’s why a half-empty bottle of oil degrades so much faster than a sealed one.

- Light: Sunlight, and even artificial light, triggers photo-oxidation. It rapidly degrades the oil, annihilating its precious antioxidants. This is why you should run, not walk, from any olive oil sold in a clear glass bottle.

- Heat: Warm temperatures accelerate every chemical reaction that ruins olive oil. Storing it next to your stove or in a warm pantry is a death sentence for its flavor.

Protecting oil from these enemies is becoming more important than ever. With global production forecasted to dip by about 10% in the 2025/26 crop year—from 3.331 million metric tons down to around 3.016 million—every drop of high-quality oil counts.

The Sanctity of Proper Storage

How do the pros shield their oil from these threats? They build a fortress. For any serious producer, the gold standard for storage is large, stainless steel tanks called fusti.

These tanks are perfect for several reasons. They are completely opaque, blocking all light. They are inert, imparting no off-flavors. Most importantly, professional tanks are often topped with an inert gas like nitrogen or argon, which forms a protective blanket over the oil’s surface, keeping oxygen at bay.

The ideal storage temperature is cool, but not cold—around 14°C (57°F). This is the sweet spot that slows the aging process without causing the oil to solidify. For a deeper dive, check out our guide to olive oil storage. This is how you ensure the beautiful oil you created stays that way, from the mill all the way to the bottle.

Common Questions About Olive Oil Extraction

After walking through the entire process, from the grove to the bottle, a few questions always surface. These are the queries I hear most often, from aspiring producers and curious connoisseurs alike. Let's finally put them to rest.

What Does Cold-Pressed Really Mean?

This is the big one. "Cold-pressed" is not a marketing slogan; it is a sacred promise. It means that at no point during the milling and mixing did the olive paste exceed 27°C (80.6°F).

Why does that matter? Because you could crank up the heat to squeeze out more oil, but you would be committing an act of vandalism against its quality. Heat incinerates those beautiful, delicate aromas and destroys the polyphenols—the very compounds that give extra virgin olive oil its profound health benefits and complex flavor.

As for "first press," that phrase is mostly a charming relic from the era of hydraulic presses. With today’s centrifuges, all true extra virgin olive oil comes from a single, continuous extraction. You might see "first cold extraction," which is more accurate, but the promise is the same: keep it cool to keep it magnificent.

How Many Olives to Make One Liter of Oil?

There is no single answer to this question. The yield—how much oil you get from the olives—is a moving target, influenced by a host of factors.

As a general rule, it takes anywhere from 4 to 12 kilograms of olives to produce a single liter of oil.

What causes that enormous range?

- The Olive Itself: Some varieties are simply bursting with more oil than others.

- Harvest Time: This is a massive factor. Early harvest olives, which create intensely grassy and peppery oils, have a lower oil content. Wait until they are fully ripe, and your yield will climb, but you will trade that vibrant flavor for something much milder.

- The Weather: A good year with the right amount of sun and rain can dramatically affect how much oil the trees produce.

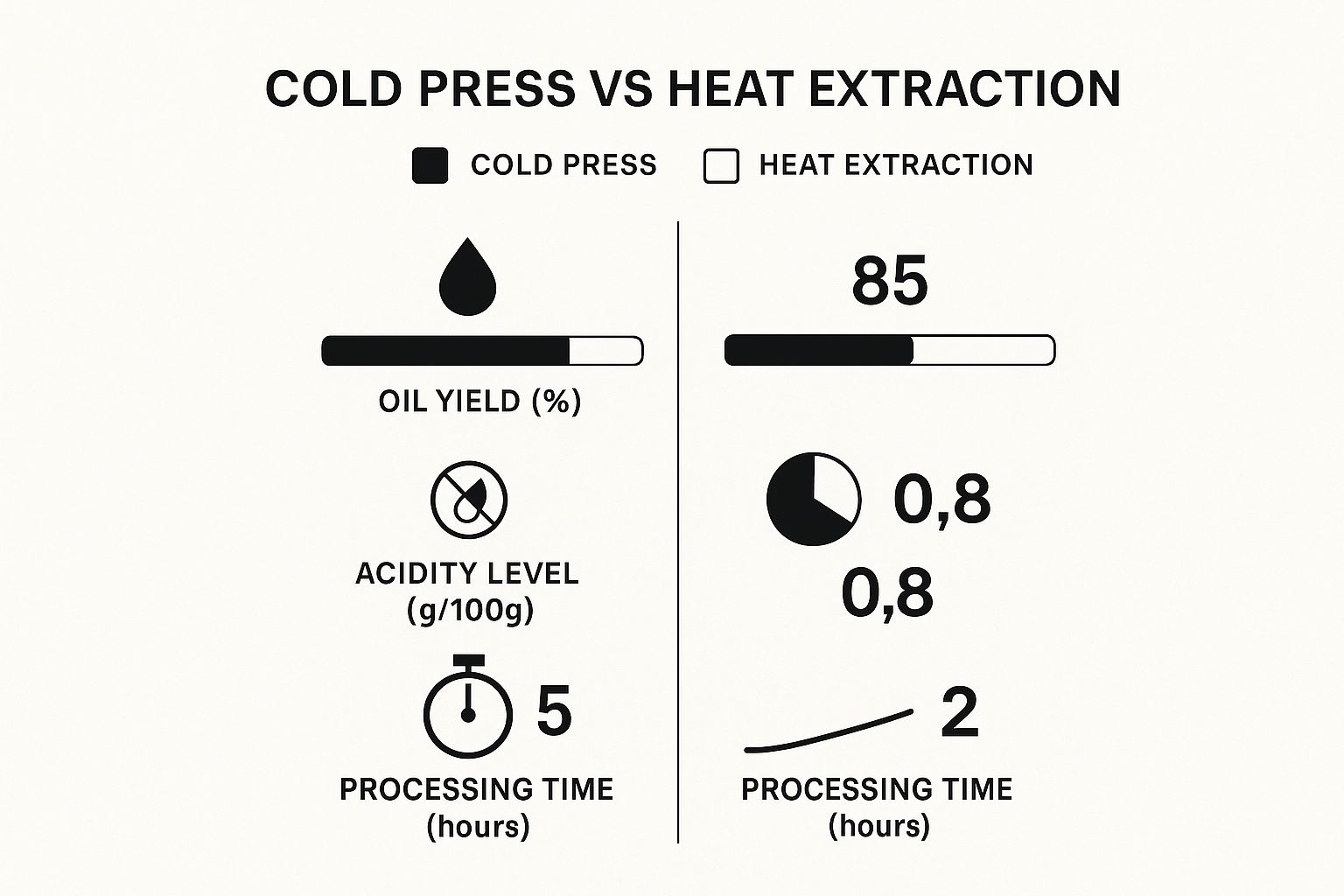

- The Equipment: A modern, efficient centrifuge will always extract more oil than a traditional press. It is simply a superior technology for this task.

Why Does Fresh Olive Oil Taste Peppery or Bitter?

If you take a sip of fresh, high-quality olive oil and feel a bitter sensation on your tongue or a peppery sting in the back of your throat, congratulations. That is not a flaw. That is the taste of excellence.

Those sensations are the hallmarks of a fresh, high-quality extra virgin olive oil. They come directly from a high concentration of powerful antioxidants called polyphenols.

One specific compound, oleocanthal, delivers that peppery kick and also happens to be a potent natural anti-inflammatory. If an oil is just smooth, bland, and buttery, it’s a red flag. It likely means it's old, refined with heat, or simply a low-grade product. You should welcome that bite—it is the signature of quality.

Can I Really Make Olive Oil at Home?

Technically, you can try, but I must strongly advise against it. It is an incredibly laborious process that almost never yields good results without professional equipment. I've heard tales of people attempting it with mallets and cheesecloth, but the effort is monumental for a tiny amount of subpar oil.

The true enemy is oxygen. Without professional machinery, the olive paste is exposed to far too much air, which immediately triggers oxidation and rancidity. You also cannot achieve a clean separation of oil from the vegetable water, meaning whatever you produce will spoil in no time. For any decent quantity of stable, high-quality olive oil, specialized equipment is non-negotiable.

Ready to deepen your appreciation for this liquid gold? At Learn Olive Oil, we provide expert insights to help you choose, taste, and enjoy the world's finest olive oils. Start your journey with us and discover what makes a truly exceptional oil.

Leave a comment