So, how does a humble olive transform into the "liquid gold" we drizzle over salads and pasta? It's a journey that's part art, part science, blending ancient traditions with modern precision. This isn't just about squeezing fruit; it's a carefully orchestrated process where every single step matters.

Understanding this path from the grove to your kitchen gives you a whole new appreciation for what separates an average bottle of olive oil from a truly exceptional one.

From Olive Grove To Liquid Gold

Let's walk through the fascinating process that turns a simple fruit into one of the world's most prized culinary ingredients. Think of it as a race against time, where quality is won or lost at each stage.

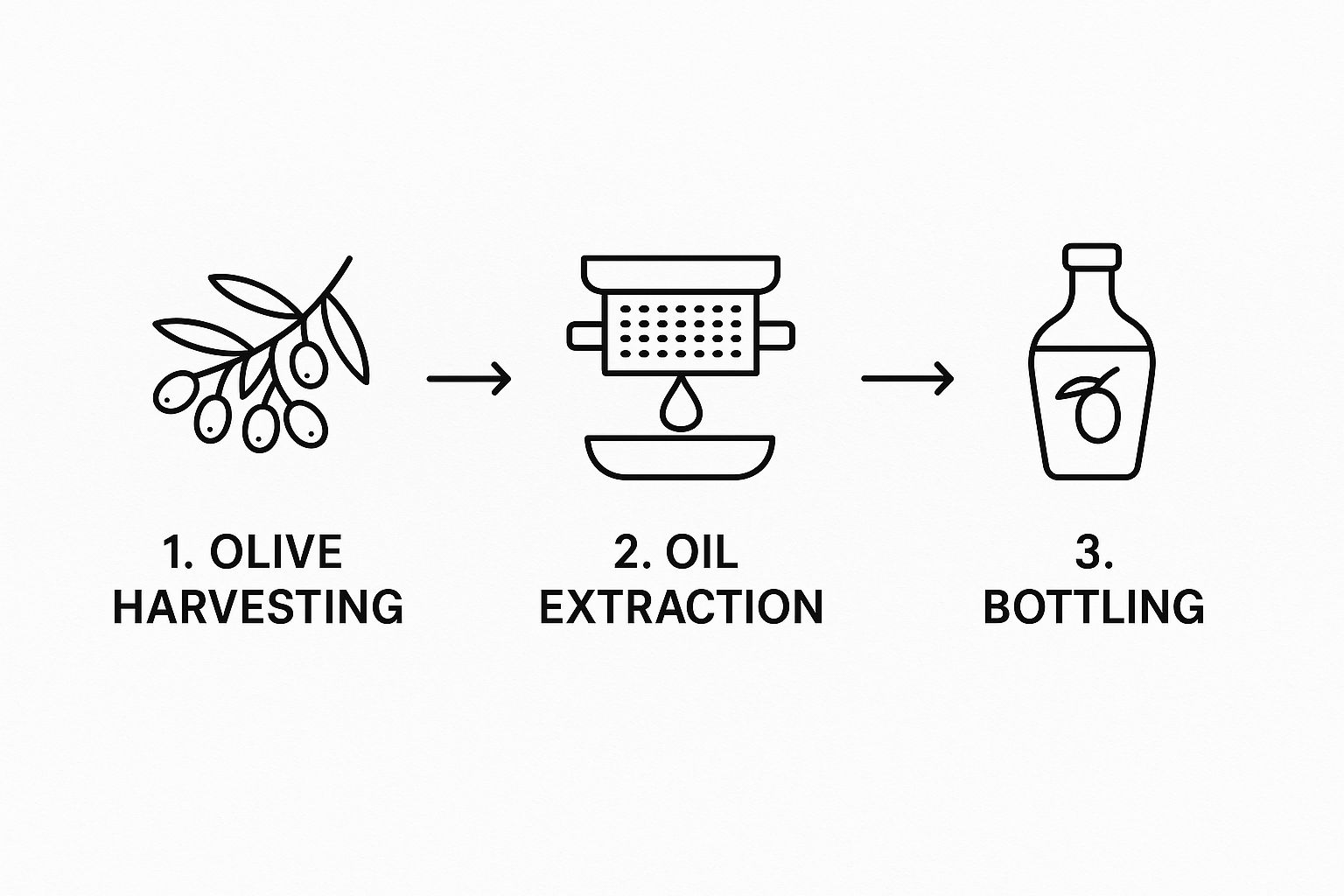

This visual gives you a great bird's-eye view of the three core phases, from picking the olives right through to bottling the finished oil.

As you can see, each step builds directly on the one before it. You can't make up for a poor harvest with great milling, which is why quality control has to be relentless from start to finish.

The Global Heartbeat Of Olive Oil

While the basic steps are universal, the real soul of olive oil production beats strongest in the Mediterranean. This is where it's not just agriculture; it's a way of life.

Countries like Spain, Italy, Greece, and Tunisia are the undisputed titans of the industry. Spain, in particular, is a powerhouse, responsible for about 40% of the world's olive oil. We're talking roughly 1.41 million tons a year. As a whole, the European Union produces around 2.1 million tons—a figure that recently jumped by nearly 40% after a tougher season. For more details, you can dive into recent olive oil market data reports.

The journey from tree to table is a race against time. The quality of the final product is a direct reflection of the care taken during harvesting, milling, and storing the oil.

A Quick Guide To The Production Stages

To really get a feel for how olive oil is made, it helps to break down the journey one step at a time. Each stage has a specific job to do, shaping the oil's final taste, aroma, and even its health benefits.

This table provides a simple overview of what happens at each point in the process.

Quick Guide to Olive Oil Production Stages

| Stage | What Happens | Why It's Important |

|---|---|---|

| Harvesting | Olives are picked from the trees, either by hand or with mechanical shakers. | The timing and method are crucial. Picked too early, the oil is bitter; too late, and it's less flavorful. |

| Washing & Crushing | Olives are cleaned of leaves and dirt, then milled into a thick, uniform paste. | This breaks open the fruit's cells, starting the process of releasing the precious oil. |

| Malaxation | The olive paste is slowly churned or kneaded in a large basin for 20-40 minutes. | This encourages the tiny oil droplets to clump together, making them much easier to separate from the water and solids. |

| Extraction | The oil is separated from the solid pomace and vegetable water using a press or, more commonly, a centrifuge. | This is the moment of truth where the "liquid gold" is finally separated and collected. |

| Storage & Bottling | The fresh oil is stored in large, airtight stainless steel tanks to settle and protect it from oxygen and light. | Proper storage prevents oxidation and preserves the oil's delicate flavors and aromas until it's ready to be bottled. |

Seeing it laid out like this really highlights how each step is a critical link in the chain. From the moment an olive leaves the branch, the clock is ticking to capture its peak quality and flavor.

The Art And Science Of The Olive Harvest

The entire story of an olive oil's quality starts right here, in the grove. Long before the first machine whirs to life, the harvest itself sets the stage. This is the most crucial moment in the entire process, a delicate dance of timing, technique, and even temperature that will ultimately decide if an oil is exceptional or just… ordinary.

It's a lot like a winemaker knowing the perfect day to pick grapes. A day too soon or a day too late can completely change a wine's character. For olives, this principle is even more intense. The window for a perfect harvest can be incredibly slim.

The Critical Role Of Ripeness

When an olive is picked directly shapes the oil's flavor, its antioxidant levels, and how much oil you even get. As an olive matures on the branch, it goes through a profound transformation, and that change is exactly what you'll taste in the bottle.

-

Young, Green Olives: If you pick them early while they're still bright green, you get an oil that’s noticeably more bitter, pungent, and peppery. The yield is lower, for sure, but the concentration of healthy polyphenols (the antioxidants) is at its absolute peak. The result is a bold, grassy oil that stays fresh longer.

-

Mid-Ripeness Olives (Veraison): This is the sweet spot for many producers. The olives are caught in the act of turning from green to a reddish-purple. The oil from these olives strikes a beautiful balance—it's fruity and aromatic, less aggressive than an early harvest, but still packed with flavor and a good dose of polyphenols.

-

Fully Ripe, Black Olives: Leaving olives on the tree until they are fully ripened and black gives you the most oil. There's no question about that. But this high yield comes at a cost. The oil is much milder, almost buttery, with a dramatically lower polyphenol count. It’s also more susceptible to oxidation, meaning it has a shorter shelf life.

For anyone serious about producing premium extra virgin olive oil, the choice is clear. They almost always target that early-to-mid-ripeness stage, willingly sacrificing a larger quantity for the complex flavors and health benefits that make an oil truly great.

The harvest date is a strategic decision. Pick early, and you get less oil but one that's bursting with polyphenols and bold flavor. Wait longer, and you maximize your volume but lose that complexity and antioxidant punch.

Hand-Picking Vs. Mechanical Harvesting

Once the producer has decided when to pick, the next question is how. The two main approaches—the old-world tradition of hand-picking and the modern efficiency of mechanical harvesting—each have their pros and cons that directly affect the final product.

Hand-Picking The Olives

This is the classic, gentle method. Workers use small, handheld rakes to carefully comb the olives off the branches, letting them fall onto nets spread out on the ground. It’s meticulous work.

Think of it like selecting the most perfect, unblemished apples at the market. By handling the fruit so gently, you prevent the bruising and tearing that can kickstart oxidation and fermentation before the olives even leave the grove. For the absolute highest tier of extra virgin olive oil, this careful handling is non-negotiable.

Mechanical Harvesting Methods

For larger commercial groves, picking every olive by hand simply isn't feasible. Here, mechanical shakers come into play. These machines clamp onto the tree's trunk or main limbs and vibrate them powerfully, shaking the olives loose onto the collection nets.

The efficiency is undeniable; you can harvest an enormous number of olives in a fraction of the time. The main risk, however, is bruising. The vigorous shaking can easily damage the fruit. This is exactly why the next step is a frantic race against the clock. Any bruised or broken olives must be rushed to the mill—ideally within just a few hours—to be crushed before any off-flavors or defects have a chance to develop in the oil.

From Fruit to Paste: Releasing the Oil

Once the olives are cleaned and ready, we get to the heart of the process. This is where the magic really begins—transforming solid fruit into a paste to release the precious oil locked inside. This isn't a single step, but two distinct and equally vital stages: crushing and malaxation.

First, we need to break down the olives into a thick, uniform paste. This is the initial, brute-force part of the job. After that, the paste goes through a slow, gentle mixing phase. This second step is all about developing flavor and getting the oil ready for extraction. Let's dig into how it all works.

The Crush: Two Paths to a Perfect Paste

The goal here is simple: tear the olive flesh and break the pits to create a paste. This ruptures the tiny sacs, called vacuoles, inside the fruit's cells where the oil is stored. But how you crush the olives makes a world of difference to the final character of the oil. It’s a classic choice between tradition and modern efficiency.

Today, producers mainly use one of two methods:

-

Traditional Stone Mills: This is the old-world way. Huge, heavy granite wheels, sometimes weighing several tons, slowly grind the olives in a stone basin. It's a gentle process that creates very little heat, which is fantastic for preserving the oil's delicate aromas. The resulting paste is a bit coarse and uneven, but many artisans swear this creates a more complex and nuanced flavor.

-

Modern Hammer Mills: This is the workhorse of the modern industry. Instead of slow grinding, a hammer mill uses metal blades spinning at thousands of RPMs to pulverize the olives against a screen. It’s incredibly fast and creates a much finer, smoother paste. This more aggressive approach tends to release more of those green, pungent, peppery flavors that are so prized in robust olive oils.

The choice between a stone mill and a hammer mill is really a choice between rustic complexity and modern intensity. Think of it as using a classic mortar and pestle versus a high-powered food processor. Both get the job done, but the results are entirely different.

Malaxation: The Art of the Slow Mix

After the olives are crushed, the paste isn't ready for the press just yet. The next step is malaxation, and it's all about patience. The olive paste is moved into a large, horizontal trough where spiral blades slowly churn and knead it for 20 to 40 minutes.

This isn't just aimless stirring. Malaxation is a crucial phase where the oil begins to come together. The slow, continuous mixing encourages the microscopic oil droplets released during the crush to find each other and merge, forming larger drops. This makes it far easier to separate the oil from the water and solid pulp later on.

If you were to skip or rush this step, a huge amount of oil would stay trapped in the paste, and your final yield would be disappointingly low.

Temperature: The Secret to "Cold-Pressed" Quality

The single most important factor during malaxation is temperature. This is where the term "cold-pressed"—or more accurately, "cold extraction"—comes into play.

For an oil to earn this designation, the olive paste has to stay below 27°C (80.6°F) through the entire malaxation and extraction process. Here’s why that number is so critical:

- Protecting Flavor: Heat makes volatile aromatic compounds evaporate. Keeping things cool ensures those delicate fruity and floral notes stay in the oil.

- Preserving Nutrients: Those wonderful polyphenols and antioxidants that give extra virgin olive oil its health benefits and peppery kick are degraded by heat.

- Preventing Spoilage: Warmth speeds up oxidation, the process that creates off-flavors and defects, ultimately lowering the oil's quality and shortening its shelf life.

Sure, a producer could crank up the heat to squeeze a little more oil out of the paste, but that extra quantity comes at a huge cost to quality. For anyone serious about making true extra virgin olive oil, keeping the temperature down during malaxation isn't just a guideline—it's the golden rule. It's what separates the good stuff from the rest.

Separating The Oil From The Paste

After the slow, patient work of malaxation, the olive paste is finally ready for the moment of truth. This is where the magic really happens—the crucial step where liquid gold is finally coaxed out from the solids and water. The entire olive oil manufacturing process hinges on this stage, and the method a producer chooses will profoundly shape the oil's final character, from its taste and quality to how much oil they actually get.

Essentially, there are two roads a miller can take: the ancient, traditional press or the swift, modern decanter centrifuge. Each approach has its own personality, its own set of pros and cons, representing a choice between time-honored tradition and cutting-edge precision.

The Classic Press Method

When you imagine old-world olive oil making, you're probably picturing the traditional press. It's a timeless and visually striking method that relies on pure, brute force to squeeze the oil from the paste.

Here's a look at how it unfolds:

- Spreading the Paste: First, the thick olive paste is carefully spread onto round, fibrous mats. In the old days these were made of hemp or coconut fiber, but today they are typically durable nylon.

- Stacking the Mats: These mats are then stacked high, one on top of the other, with a metal disc slipped between each one to help spread the pressure out evenly.

- Applying Pressure: The whole stack gets slid under a hydraulic press. Immense pressure is applied, slowly forcing the liquid—a mixture of oil and water—to trickle out and run down the sides.

- Gravity Separation: This liquid is collected in large vats where gravity does the rest of the work. Since oil is lighter than water, it naturally floats to the top over several hours, allowing the miller to carefully skim it off.

While it’s a romantic process steeped in history, this method leaves the oil exposed to air for a long time, making it much more susceptible to oxidation. That exposure can dull the flavor and shorten the oil's shelf life.

The Modern Decanter Centrifuge

Walk into most modern olive oil mills today, and you won't see a press. Instead, you'll find the decanter centrifuge. Think of it as an industrial-sized, high-tech salad spinner that uses incredible speed to achieve a cleaner, faster separation.

The olive paste is pumped into a horizontal drum that spins at mind-boggling speeds—often over 3,000 rotations per minute. The intense centrifugal force instantly separates everything inside by density. The heaviest solids (what we call pomace) are flung against the outer wall, while the lighter water and the very lightest oil form distinct layers closer to the center.

The centrifuge is the heart of the modern mill. It accomplishes in minutes what used to take hours, providing a level of control and hygiene that has elevated quality standards for extra virgin olive oil across the globe.

This rapid, enclosed process dramatically cuts down the oil’s contact with oxygen, which is absolutely critical for preserving its delicate, fresh flavors and antioxidant properties. The sheer efficiency of the centrifuge also plays a massive role in the global supply chain, which is especially important when you consider how much production can fluctuate. For instance, some agricultural forecasts and their impact on the market suggest a potential 10% decline in worldwide production for the 2025/26 crop year, driven by climate issues and the natural boom-and-bust cycles of olive trees.

Two-Phase Versus Three-Phase Centrifuges

To add another layer, modern millers must choose between two types of centrifuges. This isn't just a technical detail; it has major implications for both the quality of the oil and the mill's environmental footprint.

Three-Phase Decanter:

- Outputs: This system separates the paste into three things: oil, water, and a fairly dry solid pomace.

- Process: To get this clean separation, a small amount of warm water must be added to the paste.

- Impact: Adding water is effective, but it has a downside—it can wash away some of the precious, water-soluble polyphenols (the antioxidants that give olive oil its peppery kick and health benefits). It also creates a lot of wastewater, a pollutant that’s tricky to dispose of responsibly.

Two-Phase Decanter:

- Outputs: This system gives you just two outputs: oil and a single, wet pomace that contains both the solids and the vegetation water.

- Process: The key here is that no extra water is added.

- Impact: Today, this is widely considered the superior method for producing high-quality oil. By avoiding extra water, it preserves a higher concentration of polyphenols, leading to a more robust, flavorful, and healthful oil. It also solves the wastewater problem, as the water stays with the pomace, which can then be repurposed for things like biofuel or animal feed. The only trade-off is that this "wet pomace" is heavier and a bit more challenging to handle.

Preserving Quality Through Final Processing

Just because the oil has been separated doesn't mean our work is done. Far from it. These final steps in the olive oil manufacturing process are every bit as important as the harvest and milling. They are what lock in the quality, flavor, and freshness until that bottle finally lands in your kitchen.

Think of these last stages—filtration, storage, and bottling—as the oil's guardians. Their job is to protect this liquid gold from its three biggest enemies: oxygen, light, and heat.

The Great Debate: Filtered vs. Unfiltered

Once the centrifuge has done its job, the fresh oil is still a bit murky, full of tiny bits of olive fruit and water. This is where the producer faces a choice that essentially splits the olive oil world in two: to filter, or not to filter?

-

Filtered Olive Oil: The vast majority of high-quality extra virgin olive oil you'll find is filtered. Here, the oil is gently passed through a filter, often made of cotton wadding, to catch all that leftover sediment. The result is a brilliantly clear, stable oil with a much longer shelf life. Why? Because those leftover fruit particles can ferment and spoil the oil over time.

-

Unfiltered Olive Oil: Sometimes called olio nuovo (literally "new oil"), this is oil that’s bottled straight away, sediment and all. It’s cloudy, with a punchy, almost peppery character that some connoisseurs absolutely love. The catch is its short lifespan. It really needs to be used within a few months before that sediment starts to turn it rancid.

A great analogy is fresh-squeezed orange juice. Unfiltered oil is like the pulpy, straight-from-the-juicer kind—intensely flavorful but best enjoyed right away. Filtered oil is more like the clear, pulp-free juice you buy at the store, offering a more refined taste and a longer-lasting freshness.

For most people who want a reliable, high-quality oil in their pantry, filtered is the way to go. A proper filtration doesn't strip the oil of its flavor or health benefits; it just makes it more stable for the journey to your table.

Guarding the Gold: Proper Storage

Whether it’s filtered or not, the brand-new oil needs a safe place to rest and settle before it’s ready for bottling. This isn't just a holding pattern; it's a carefully controlled period of stabilization that can last for several weeks or even a couple of months.

The fresh oil is pumped into massive, airtight storage tanks. In any serious operation, these will be made of stainless steel. This material is completely inert, meaning it won't react with the oil or pass on any metallic, off-flavors.

These tanks are kept in a cool, dark environment, ideally holding a steady temperature around 18°C (64°F). To go a step further, many top producers will pump an inert gas, like nitrogen, into the top of the tank. This pushes out the oxygen, stopping oxidation—the chemical reaction that makes oil go rancid—dead in its tracks.

This isn’t just a nice-to-have; it's a non-negotiable step for crafting premium olive oil. It gives the flavors time to meld and mature, all while being protected from the elements.

The Final Step: Bottling for Protection

The very last leg of the journey is bottling. The container isn't just for looks; it's the final line of defense for the oil's quality. You'll almost never see a true extra virgin olive oil in a clear glass bottle, and there's a very good reason for that.

Light is a killer for good olive oil, triggering a process called photodegradation that quickly ruins the flavor. To prevent this, producers use packaging specifically designed to block out those harmful UV rays.

Common Protective Packaging:

- Dark Glass Bottles: Dark green or deep brown glass is the classic choice. It does a great job of blocking light while still letting you see the beautiful oil inside.

- Tins or Cans: Opaque metal tins are another fantastic option. They offer total protection from light and have the added benefit of being shatterproof.

- Ceramic Bottles: While a bit less common, opaque ceramic bottles provide excellent light protection and often give the product a premium, artisanal feel.

By choosing the right container, producers ensure all the hard work they put into the olive oil manufacturing process pays off, delivering an oil that’s as vibrant and healthy as the day it was made.

How To Read An Olive Oil Label

Now that you’ve seen the entire olive oil manufacturing process from the grove to the bottle, you're ready to put that knowledge to work in the grocery aisle. An olive oil label isn't just a pretty design; it’s a report card that tells the story of the oil inside. Learning to read it is the key to confidently picking a great bottle every time.

Think of the label as the final chapter. Every term gives you clues about how the olives were treated, the quality of the extraction, and what you can expect when you get it home.

Decoding The Grades Of Olive Oil

The single most important piece of information on that label is the grade. It’s a direct reflection of the quality of the olives and the care—or lack thereof—taken during production. It cuts right to the chase.

You'll generally find three main grades on the shelf:

-

Extra Virgin Olive Oil (EVOO): This is the top of the pyramid. The term "Extra Virgin" is your guarantee that the oil was made only with mechanical methods, like crushing and spinning in a centrifuge. No chemicals, no excessive heat. To earn this title, the oil has to pass tough chemical analysis and, just as importantly, a taste test by a certified panel to ensure it has zero defects. It’s the purest expression of the olive.

-

Virgin Olive Oil: Like EVOO, this oil is also extracted mechanically without heat or chemicals. The difference? It’s allowed to have some minor flavor defects and slightly higher acidity. While it's still a natural, unrefined product, it just doesn't meet the perfect standards of "Extra Virgin." You won't see this grade very often, as producers usually refine it instead.

-

Refined Olive Oil (or simply "Olive Oil"): This is what happens to virgin oils that don't make the cut. They're sent to an industrial refinery to be treated with heat, chemicals, and filtration to strip away all the unpleasant flavors and aromas. What's left is a neutral, colorless oil. To give it some character back, producers blend in a small amount of virgin or extra virgin olive oil.

Simply put, "Extra Virgin" signifies a flawless olive oil manufacturing process. It’s your assurance of a natural, high-quality product made with care, straight from the olive. Anything else has either minor flaws or has undergone significant industrial refining.

Understanding Key Label Terms

Beyond the grade, a few other terms can give you a deeper insight into the oil's quality and character. These are the details that separate a truly exceptional oil from a mediocre one.

"Cold-Pressed" or "Cold Extraction"

This term takes you right back to the mill, specifically to the malaxation and extraction steps. It’s a certification that the olive paste was kept below 27°C (80.6°F) during the entire process. As we covered, low temperatures are absolutely critical for preserving the delicate flavors, aromas, and healthy polyphenols. By definition, any oil labeled Extra Virgin must be cold-extracted.

Harvest Date

This might be the most important date on the bottle. Olive oil isn’t like wine; it doesn’t get better with age. A "best by" date can be arbitrary, but the harvest date tells you exactly when the journey from fruit to oil began. The closer you are to that date, the more vibrant and healthful the oil will be. As a rule of thumb, try to use your olive oil within 18-24 months of the harvest.

Common Questions About Making Olive Oil

Once you start to understand the journey from tree to bottle, a few common questions always seem to pop up. Getting answers to these really helps connect the dots and deepens your appreciation for what goes into that bottle in your kitchen.

Let's dig into some of those frequently asked questions.

How Many Olives Does It Take to Make Oil?

It's a great question, and the answer really puts the value of good olive oil into perspective. You might be surprised by how much fruit is needed.

On average, it takes about 5 to 6 kilograms (or 11 to 13 pounds) of olives to get just a single liter of extra virgin olive oil. That number can swing a bit, though, depending on a few key things:

- Olive Variety: Just like grapes for wine, some olive types are simply juicier and more oil-rich than others.

- Ripeness: Greener olives, harvested early for that peppery flavor, give less oil than their fully ripened, black counterparts.

- Harvest Time: The specific conditions of the season—the sun, the rain—all affect how much oil the olives produce.

- Extraction Method: Modern, high-efficiency mills can coax out more oil than older or less advanced equipment.

You'll often see "first press" on labels, but that term is mostly a romantic throwback to old screw presses. With today's technology, all true extra virgin olive oil comes from the first—and only—extraction. The term that really matters now is 'cold extraction,' which means the temperature was kept below 27°C (80.6°F) to preserve the oil's delicate flavors and health benefits.

What Happens to the Olive Leftovers?

After the precious oil has been spun out, you're left with a whole lot of pits, skins, and pulp. This leftover mash is called pomace, and thankfully, it doesn't just go to waste. The olive world is surprisingly resourceful.

This pomace is often sent to a different kind of facility where solvents are used to squeeze out every last bit of remaining oil. The resulting product is refined and sold as pomace oil. The dried-out solids that remain—the pits and pulp—can be burned as a biofuel (sometimes to power the mill itself!) or used as a nutrient-rich feed for livestock. It’s a great example of a circular system that minimizes waste.

At Learn Olive Oil, we believe that knowing the story behind your food makes it taste even better. We're here to give you the expert knowledge you need to explore, taste, and cook with confidence. Discover the World of Premium Olive Oil with us.

Leave a comment