The extraction of olive oil is a story of separation. At its heart, it's a simple, ancient quest: to liberate the precious oil from the water and solids of the olive fruit. For the world's finest oils, those crowned extra virgin, this must be achieved by purely mechanical means. No chemical shortcuts. No punishing heat. Just a pure, physical art form.

This journey is a frantic race against time, a drama that unfolds the instant an olive is plucked from its branch. Every decision, every moment from that point forward, will carve the final character of the oil—its flavor, its aroma, its soul—that will one day grace your kitchen.

The Journey from Ancient Grove to Modern Mill

Imagine yourself in a sun-drenched olive grove. The timeless, earthy scent you’re breathing is the overture to a ritual that has transformed fruit into liquid gold for over 6,000 years. It all begins with the harvest. For the world's most fanatical producers, timing isn't just important—it's an obsession. Olives are plucked at the precise moment of ripeness to seize the perfect balance of flavor and life-giving compounds.

The second an olive parts from its branch, a clock begins to tick. Loudly. It’s a mad dash to rush the fruit from the grove to the mill. You’ll often hear passionate producers speak of crushing their olives "within hours" of harvest. This isn't just a marketing slogan; it is the first commandment in the gospel of incredible olive oil.

From Fruit to Pure Oil

The idea of extraction is wonderfully simple. You’re merely separating the valuable oil from the olive’s water and solids (the leftover pulp is called pomace). The true magic, however, lies in how this is done. Every choice made during the process is a battle waged against the two great enemies of quality: heat and oxygen.

The entire process is a fight against time and oxidation. Every choice carves out the final taste, aroma, and nutritional power of the oil, ultimately determining whether a bottle earns the 'extra virgin' crown.

Exposure to either will rapidly degrade the oil. It invites off-flavors to the party and mercilessly destroys the very polyphenols that give premium olive oil its signature peppery fire and legendary health benefits.

To truly understand what makes an olive oil magnificent, you must see the process as a series of distinct, unskippable stages. This quick overview reveals the core journey from sun-dappled tree to cool, dark bottle.

The Core Stages of Olive Oil Extraction

| Stage | Objective | Impact on Quality |

|---|---|---|

| Harvesting & Transport | Pick olives at peak ripeness and move them to the mill immediately. | Prevents bruising, fermentation, and oxidation. Timing is everything. |

| Cleaning & Washing | Remove leaves, twigs, dirt, and other debris from the fruit. | Ensures that only pure olive fruit goes into the mill, avoiding bitter or earthy taints. |

| Crushing / Milling | Grind the whole olives into a thick, uniform paste. | Breaks open the fruit cells to release the oil droplets, preparing them for separation. |

| Malaxation (Mixing) | Gently and slowly stir the olive paste. | Allows small oil droplets to clump together, making them easier to extract. |

| Extraction | Separate the oil from the water and solid pomace. | The critical separation step. Modern methods use centrifuges; traditional ones use presses. |

| Filtration & Storage | Remove any remaining sediment and store the oil properly. | Creates a clear, stable oil with a longer shelf life, protecting it from further oxidation. |

Each of these steps is a link in a chain. A weakness in any one of them will compromise the final product. Understanding this flow—from the sun on the tree to the cool steel of the mill—is the first step to truly appreciating the craft behind this liquid gold.

The Soul of Tradition: Ancient Pressing Methods

Long before gleaming stainless steel and silent, humming centrifuges became the norm, the making of olive oil was a far more primal affair. It was a craft rooted in stone, fiber, and the slow, deliberate application of immense pressure. This ancient method is where the term “cold pressed” truly earned its meaning, a ritual designed to coax oil from fruit without the corrupting influence of heat.

This journey began not with a metal grinder, but with colossal granite millstones. Imagine these massive wheels, weighing several tons, turning with a slow, hypnotic rhythm. They would gently crush the whole olives—pit and all—into a thick, fragrant paste. The secret to this technique is its unhurried pace. The slow grinding prevents the buildup of friction and heat, the mortal enemies of the oil's delicate aromas and fragile flavors.

The Art of the Press

Once the paste was ready, the next step was a hands-on, almost sculptural ritual.

- Mat Stacking: Workers would meticulously spread the olive paste onto round, woven mats, traditionally made from hemp or coconut fiber.

- Building the Tower: These mats were then stacked one on top of the other, forming a tall column of alternating fiber and olive paste.

- Applying Pressure: The entire stack was moved under a hydraulic press. With incredible yet gentle force, the press would squeeze the tower, causing the golden-green oil to slowly weep out and collect in vats below.

This was the original “first press.” The term has since devolved into a marketing buzzword, a pale ghost of its former meaning. You can learn more about what the term 'first press' really means in our detailed guide.

The Character of Tradition

So, why do some artisan producers still bother with such a laborious method? The answer is simple: character. The oil produced this way often possesses a distinct personality—a softer, sometimes buttery flavor that sets it apart from more modern oils. It’s a testament to the belief that patience yields a unique reward.

This traditional pressing method is less about efficiency and more about preserving a specific, historical flavor profile. It's an expression of craftsmanship where every step is deliberate and sensory.

Of course, this old-world approach isn't perfect. The fiber mats are notoriously difficult to clean, and the process exposes the olive paste to far more oxygen. This increased oxidation can shorten the oil's shelf life and sometimes results in a less intense, peppery finish compared to its modern counterparts.

Even so, for its champions, the soul of tradition is a taste well worth preserving.

The Modern Marvel of Centrifugal Extraction

Forget the romantic image of heavy stone wheels and woven mats. When you step into a modern olive mill, you're entering a world of gleaming stainless steel and precision engineering. This is where the vast majority of today's high-quality extra virgin olive oil is born, not from a press, but from a machine called a centrifugal decanter.

This high-tech method swaps the slow, gentle squeeze of a press for the raw, invisible power of physics. It’s a continuous, closed system that has become the gold standard for its incredible efficiency, impeccable hygiene, and most importantly, its ability to shield the oil from its greatest foe: oxygen. This is the engine of the modern olive oil world.

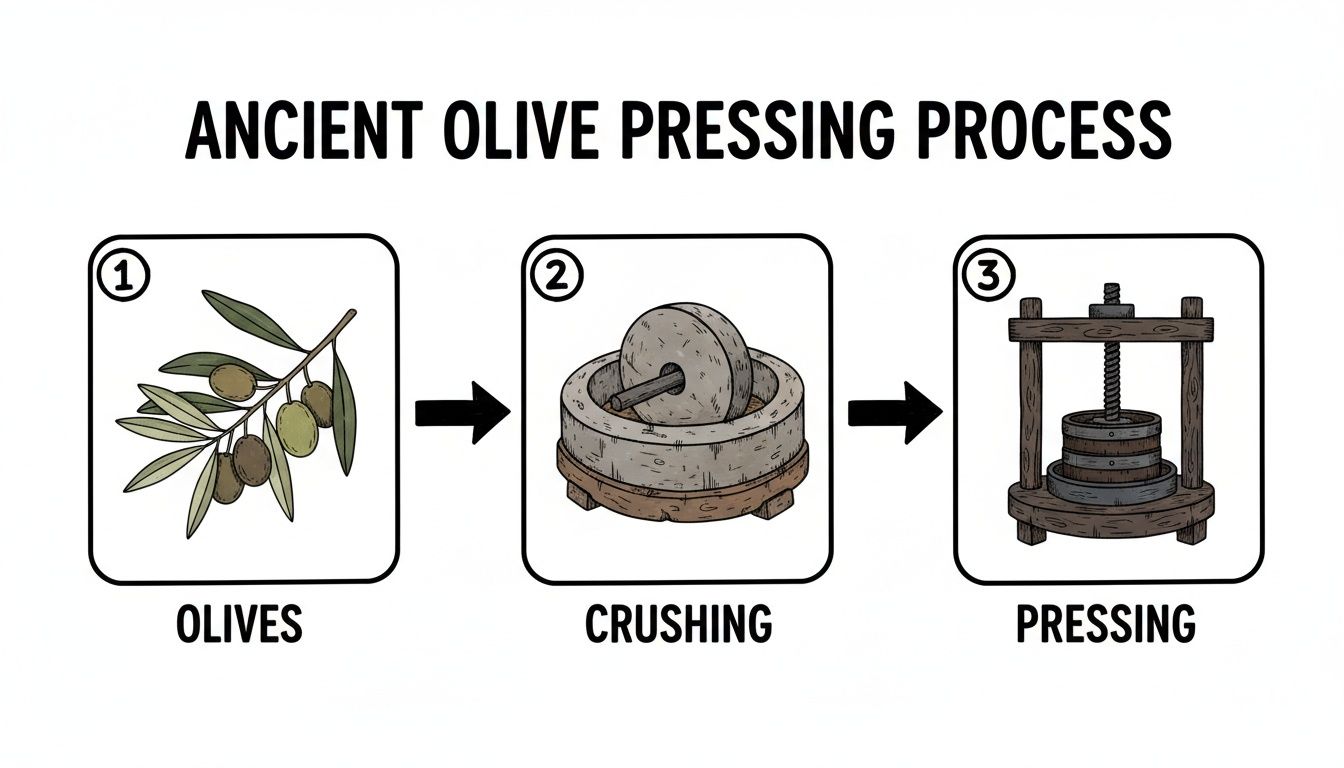

The image below shows the simple, direct journey from olive to oil using the ancient pressing methods we just discussed.

It highlights the stark contrast with the sophisticated, multi-stage ballet of today's centrifugal systems.

Traditional Press vs Modern Centrifuge: A Head-to-Head Comparison

To truly grasp the technological leap, it helps to see the two methods side-by-side. The following table breaks down the key differences between the classic hydraulic press and the modern centrifugal decanter, showing the trade-offs in everything from speed to the final product's quality.

| Feature | Traditional Press (Hydraulic) | Modern Centrifuge (Decanter) |

|---|---|---|

| Extraction Method | Mechanical squeezing of olive paste spread on fiber mats. | High-speed spinning (centrifugal force) to separate components. |

| Speed & Volume | Slow, batch process. Lower throughput. | Fast, continuous process. High throughput. |

| Oxygen Exposure | High. Paste is exposed to air during mat-spreading and pressing. | Very low. The entire system is sealed, minimizing oxidation. |

| Hygiene | Challenging. Fiber mats are difficult to clean perfectly. | Excellent. Stainless steel is easily and thoroughly cleaned. |

| Control | Less control over temperature and other variables. | Precise control over temperature, speed, and timing. |

| Oil Quality | Can produce high-quality oil, but prone to flavor defects. | Consistently clean, stable oil with vibrant flavors. |

| Labor | Labor-intensive and requires significant manual skill. | Highly automated, requiring skilled operators. |

While the traditional press holds a certain old-world charm, it's clear why the centrifuge has become the weapon of choice for producers aiming for the highest levels of quality and consistency.

From Hammer Mill to Liquid Gold

The modern journey from olive to oil is a masterclass in controlled transformation. Think of it as a three-act play where technology ensures every drop of flavor and nutritional goodness is meticulously preserved. For an even deeper look, you can explore the complete olive oil manufacturing process in our in-depth guide.

Here’s how the magic happens, step-by-step:

-

1. The Hammer Mill: First, freshly cleaned olives are dropped into a hammer mill. This ferocious machine instantly pulverizes the whole fruit—pit and all—into a uniform, thick paste. It’s brutally efficient and far more consistent than an old stone mill, creating the perfect texture in mere moments.

-

2. The Malaxer: From the mill, the olive paste is pumped into a malaxer. Imagine a long, stainless steel trough with slowly rotating blades. The goal here isn't more crushing, but a gentle kneading of the paste for about 20 to 40 minutes. This slow, hypnotic stirring coaxes the tiny oil droplets scattered throughout the paste to find each other and merge into larger drops, making them far easier to separate in the next act.

-

3. The Decanter Centrifuge: Now for the main event. The paste is pumped into a horizontal centrifuge that spins at unimaginable speeds—we’re talking thousands of revolutions per minute. The intense force it generates does the work of the press, but with an authority and precision that old-world methods could only dream of.

The Magic of Centrifugal Force

Have you ever been on one of those spinning amusement park rides that pins you to the wall? The decanter centrifuge operates on that exact same principle. Inside the rapidly spinning drum, this crushing force instantly sorts the olive paste into its three components based on their different densities.

The centrifuge uses pure physics to create distinct layers: the heavy solid pomace is flung to the outside wall, the lighter water forms a layer just inside that, and the lightest of all—the precious olive oil—collects in the very center.

Each layer is then siphoned off through its own dedicated exit pipe. Because this entire drama unfolds in a sealed, oxygen-free environment, it's a game-changer. By virtually eliminating oxidation, the centrifuge locks in the fresh, vibrant flavors and preserves the delicate, peppery polyphenols that make an elite extra virgin olive oil so special.

This method gives producers an astonishing degree of control, resulting in an oil that is cleaner, more stable, and often more intensely flavorful.

How Extraction Defines What's in Your Bottle

Does the method used to coax oil from an olive really matter? It matters more than anything. It's quite possibly the single biggest factor separating a vibrant, health-boosting superfood from a bland, generic cooking fat. Every choice made in the mill directly shapes the experience you have at your table.

Think of the extraction process as a gatekeeper. It alone decides which of the olive's most precious compounds—the antioxidants, the vitamins, the life-extending polyphenols—actually make it into the bottle you buy. A sloppy, careless process lets them escape, while a masterful one carefully seals them inside.

This is where you'll see terms like ‘cold extraction’ or ‘cold pressed’ on a label. This isn't just marketing poetry; it's a sworn oath. It signals that the entire process was kept below a strict temperature ceiling of 27°C (80.6°F). Why is that number so critical? Because when it comes to making magnificent olive oil, heat is the ultimate enemy of greatness.

Heat and Oxygen: The Villains of the Story

Excessive heat acts like a wrecking ball on the delicate molecules that give extra virgin olive oil its signature peppery kick and powerful anti-inflammatory benefits. It simply obliterates them, leaving behind a muted, less flavorful, and far less nutritious oil. Oxygen is just as sinister, triggering a chain reaction of oxidation that can make the oil go rancid in a hurry.

Modern methods, particularly centrifugal extraction, are designed to handcuff these two villains with incredible precision. The sealed, swift nature of a centrifuge minimizes oxygen exposure, while sophisticated temperature controls ensure the entire process stays cool and calm. This is precisely how producers capture that fresh, green, and vibrant character we all crave. For a closer look at these amazing compounds, you can explore the science behind olive oil polyphenol content in our comprehensive article.

How the Process Shapes Flavor

The extraction method doesn't just protect the good stuff; it actively sculpts the oil's personality.

- Modern Centrifuge: This technique tends to produce oils that are robust, clean, and intensely fruity or grassy. By locking oxygen out, it preserves the sharp, peppery notes that sing of a high polyphenol count.

- Traditional Press: Oils from an old-school press are often much softer and buttery. They might lose some of that pungent intensity due to greater oxygen contact, but they offer a unique, milder flavor profile that many people adore.

Your bottle of olive oil tells a story. The extraction method is the most important chapter, revealing the producer’s commitment to preserving either the bold power of a modern centrifuge or the subtle character of tradition.

This artistry is on full display in places like Italy, where extraction is a matter of regional pride. Projections there are hitting 300,000 tons, a solid 30% climb from previous years, driven by this deep-rooted commitment to quality. At mills in Puglia, for instance, olives are often cold-pressed within hours of being picked, sometimes using traditional stone wheels and hydraulic presses to squeeze out pure extra virgin oil under that all-important 27°C threshold, locking in every last drop of goodness.

When you understand how an oil was made, you can read its story and have a much better idea of how it will taste.

Reading the Labels: A Buyer's Guide to Extraction Terms

Walking down the olive oil aisle can feel like trying to decipher a secret code. You're met with a wall of beautiful bottles, each whispering promises of quality with phrases like ‘Cold Pressed,’ ‘First Press,’ and ‘Centrifuge Extracted.’ But what do these words actually mean for the oil inside?

This is your decoder ring.

Let’s start by busting a common marketing myth. You’ll often see ‘first press’ or ‘first cold press’ celebrated on labels. While this sounds impressive, the term is mostly a ghost from a bygone era of old-school pressing.

Today, any producer making legitimate extra virgin olive oil only processes their olives once. There simply is no second press for EVOO, making the term redundant but still very effective at catching your eye. By understanding the real language on the bottle, you can move past the pretty packaging and confidently choose an oil that truly meets your standards for flavor, quality, and health.

Decoding Key Extraction Terms

When you see terms related to the extraction of olive oil, they're telling a story about the producer’s commitment to quality. But not all terms are created equal. Some are legally defined and meaningful, while others are little more than fluff.

Here are the most important ones to know:

- Cold Pressed: This term specifically refers to oil made using a traditional hydraulic press. To earn this label, the temperature of the olive paste must have stayed at or below 27°C (80.6°F) during the entire process.

- Cold Extracted: This is the modern equivalent of ‘cold pressed’ and applies to oil made with a centrifuge. It carries the same legal weight, signaling that the temperature was strictly controlled to preserve the oil’s delicate nutrients and flavors.

- Centrifuge Extracted / Decanter Extraction: These phrases simply state the modern method used. It points to a clean, efficient process designed to minimize oxygen exposure and lock in freshness.

The most crucial takeaway is this: 'cold pressed' and 'cold extracted' are legally protected quality markers. They are a producer's sworn oath that no excessive heat was used, which is a fundamental requirement for creating true extra virgin olive oil.

Beyond the Buzzwords

While extraction terms are vital, they don’t tell the whole story. Certifications can offer another layer of assurance.

For instance, a PDO (Protected Designation of Origin) seal guarantees that the oil was produced, processed, and prepared in a specific geographic area using traditional methods. This often implies strict oversight of the entire extraction process. For a complete breakdown, check out our guide on understanding olive oil labeling.

Producers in powerhouse regions like Spain are masters of this process. Spain is the undisputed global leader in olive oil, producing a staggering 1,419,128 tons in the most recent season. This massive output, sometimes accounting for up to 50% of worldwide production, relies on precise, modern extraction—milling, malaxation, and centrifugation—all done without heat or chemicals to preserve the polyphenols that make olive oil a health elixir.

Your Olive Oil Extraction Questions Answered

We've walked through the entire process, from ancient stone mills to the gleaming stainless steel of a modern facility. But after seeing how it all works, a few lingering questions usually pop up. Let's clear up some of the most common ones to give you a complete picture of olive oil extraction.

What Does "First Cold Pressed" Really Mean on a Label?

Honestly, this phrase is mostly a nod to history—a ghost from the days of old-school hydraulic presses. "First press" meant the olive paste was only squeezed once. Today, that’s just how all extra virgin olive oil is made. There's no such thing as a "second press" for any quality oil.

The truly important part of the phrase is "cold pressed." This is a legally regulated term, and it's your guarantee that the temperature of the olive paste never went above 27°C (80.6°F) during the entire process.

Keeping things cool is absolutely essential for protecting the oil’s delicate flavors, aromas, and all those healthy antioxidant compounds. In a modern mill using a centrifuge, you might see the term "cold extracted," but it means the exact same thing: a commitment to gentle, high-quality production.

Why Is Speed So Important After Harvesting?

Think of an olive like any other fresh fruit, maybe an apple or a peach. The second you pick it from the branch, the clock starts ticking. It immediately begins to break down.

Any delay between the tree and the mill allows oxidation and fermentation to creep in, which is just a fancy way of saying the fruit starts to go bad. This decay creates unpleasant, sour flavors and sends the oil's acidity level soaring. World-class producers are absolutely obsessed with speed, with many getting their olives from the grove to the mill in a matter of hours.

This race against time is the single most critical factor in making great olive oil. It’s what locks in that peak freshness, maximizes the healthy polyphenol content, and ensures the super-low acidity that defines an extra virgin oil.

Does the Color of Olive Oil Indicate Its Quality?

This is easily one of the biggest and most stubborn myths out there. The color of olive oil—whether it’s a brilliant, almost neon green or a soft, buttery gold—tells you absolutely nothing about its quality or how it was made.

The hue comes down to just two things: how ripe the olives were when they were picked and the specific variety of the olive.

- Vibrant Green Oils: These are typically made from less ripe, early-harvest olives. They're packed with more chlorophyll, which gives them that bright green color and often a more robust, peppery, and grassy flavor.

- Golden Yellow Oils: These usually come from riper, late-harvest olives. Their flavor profile tends to be milder, smoother, and more buttery.

In fact, professional tasters use special cobalt blue glasses so they can’t see the oil's color at all. This forces them to judge it purely on aroma and taste, which are the true markers of quality. If you want to try this yourself, our guide explains how to test olive oil at home and spot a great oil from a bad one.

At Learn Olive Oil, we believe that understanding the journey from the grove to your table is the key to truly appreciating this liquid gold. We provide the expert insights you need to choose, taste, and cook with the world's best olive oils.

Discover our curated guides and resources at https://learnoliveoil.com

Leave a comment