Before a single drop of extra virgin olive oil graces your table, it has traveled an extraordinary road—a story whispered between sun, soil, and the hands of a master craftsman. The process of olive oil is less like a factory assembly line and far more like the painstaking art of fine winemaking. Every decision, every hour, every degree of temperature, profoundly shapes the flavor, aroma, and life-giving benefits locked within.

The Secret Journey of Every Drop

Every great bottle of olive oil begins its life as a humble fruit, but its metamorphosis into “liquid gold” is a tale of urgency, precision, and passion. Let me pull back the curtain on this ancient craft. I will walk you from the sun-drenched groves where the story begins, through the fragrant chaos of the mill, and into the cool, dark cellars where the fresh oil finally rests.

You are about to discover why ‘cold extraction’ is more than just a marketing slogan on a bottle, and why the harvest is a frantic, desperate race against the clock. Delivering that perfect oil from tree to table demands a symphony of coordination, much like how the world’s greatest kitchens perfect their restaurant supply chain management to ensure every ingredient arrives at its absolute peak.

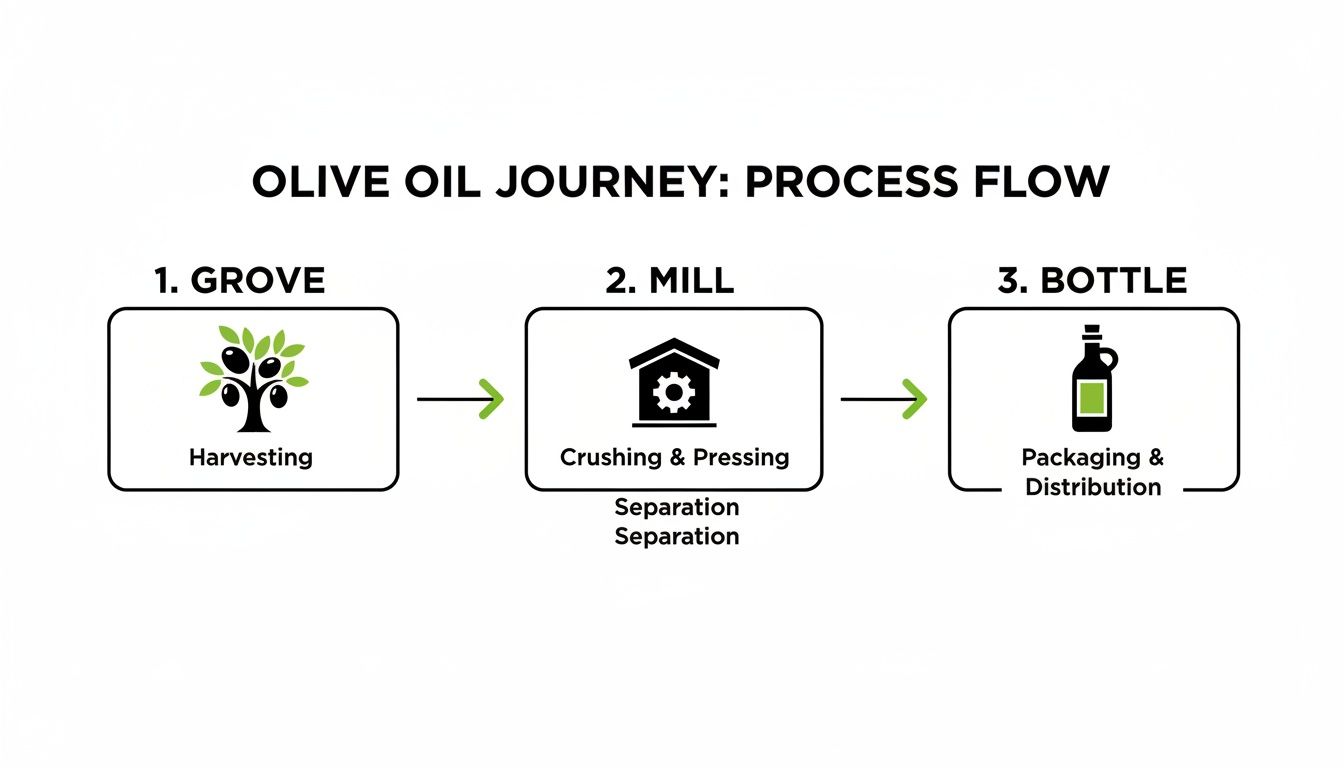

This flowchart maps out the core stages of the olive oil journey, from the tree to the mill and finally into the bottle.

Each step you see is a critical juncture where quality can either be meticulously preserved or lost forever.

Soon, you won’t just understand how olive oil is made, but why the very best oils taste so astonishingly vibrant and alive. If you wish to travel even further back in time, you can explore the ancient origin of olive oil in our detailed article.

The Harvest: A Race Against Time

The entire story of a great olive oil begins in a single, fleeting moment: the harvest. This is not just picking fruit. It is a calculated, high-stakes decision to capture the olive at its zenith of flavor and health—a choice that will define every drop of oil that ends up in your bottle.

Pick too early, and the oil will be intensely peppery, bursting with healthy polyphenols but tragically low in quantity. Wait just a week too long, and while the yield swells, the oil becomes bland and buttery, teetering on the edge of defects born from overripe, decaying fruit.

This one decision—when to pick—is the first and most critical act in defending an oil's quality. Every great producer understands this in their bones. It sets the stage for everything that follows.

How the olives are picked is just as crucial. Picture the timeless art of hand-raking, where workers gently comb olives from branches onto vast nets spread below. It is slow. It is expensive. But it is incredibly gentle, preventing the bruising that ignites fermentation and can instantly ruin an oil’s potential. To learn more about the different methods, check out our guide on olive oil harvesting techniques.

Speed and Scale in the Modern Grove

Of course, hand-picking isn’t always practical. For larger estates, modern mechanical shakers are a godsend. These machines clamp onto the tree trunk and vibrate it with astonishing force, sending a shower of olives raining down. The true advantage here is speed—an absolute necessity when tons of fruit must get from the grove to the mill in mere hours.

And it is a race. A serious one. The second an olive is plucked from its branch, a clock starts ticking. A bruised, damaged, or delayed olive is the first domino to fall on the path to a defective oil. The industry gold standard is to get the fruit from tree to mill in under 12 hours, but the world's most fanatical producers often achieve it in less than six.

This sense of urgency is palpable everywhere, especially in the sun-drenched groves of Andalusia, Spain—the beating heart of the olive oil world. Spain has been the undisputed global leader for decades. During one record-breaking season, worldwide olive oil production soared to an incredible 3.507 million tons. That staggering volume demonstrates just how vital an efficient, careful harvest is to the entire enterprise. You can read more about global olive oil production at Olive Oil Times.

Ultimately, whether by hand or by machine, the goal is always the same: deliver perfect, unbroken fruit to the mill as fast as humanly possible to lock in every last drop of fresh, vibrant flavor.

From Fruit to Paste: Inside the Mill

The moment the olives cross the threshold of the mill—what the Italians call a frantoio—the race against time becomes a flat-out sprint. This is not merely a processing plant; it is the sacred space where the fruit’s potential is either perfectly realized or lost forever. The clock that began ticking in the grove is now screaming.

First, the olives receive a quick but vital cleaning. A powerful current of air blasts away leaves, twigs, and other field debris. Even a few stray leaves can impart a bitter, woody taste—a fatal flaw in a top-tier product.

Once clean, the olives face their most dramatic transformation: the crushing. Banish those romantic images of giant stone wheels slowly grinding the fruit. Modern, world-class production relies on the swift, brutal efficiency of a stainless steel hammer mill.

The Art of Crushing and Mixing

This powerful machine pulverizes the olives—pits and all—in a matter of seconds. The entire purpose is to violently rupture the fruit’s cellular walls, releasing the microscopic droplets of oil locked within. What emerges is a thick, intensely fragrant, and often brilliantly colored olive paste.

From the crusher, this paste is immediately pumped into a tank called a malaxer for a process known as malaxation. This is not a violent churning. Think of it more as a slow, deliberate dance. For 20 to 40 minutes, the paste is gently folded over itself in a tightly controlled environment.

This gentle agitation serves a simple purpose based on physics: it coaxes the tiny, scattered oil droplets to collide and coalesce into larger drops. These bigger drops are far easier to separate from the solid fruit matter and water in the next step. This is where the miller's experience becomes priceless.

Malaxation is where an oil’s soul is forged. It's a delicate balance of time and temperature. A few minutes too long or a single degree too high, and the precious, volatile aromas will vanish into the air, while oxygen begins its destructive work on the healthy polyphenols.

The miller is constantly observing, using sight, smell, and even touch to know the precise moment to stop. They adjust the duration and temperature based on the specific olive variety, its ripeness, and even the day's humidity. It is the very heart of the process of olive oil.

Why Temperature Control Is Everything

This entire operation is conducted under strict temperature control to protect the oil's fragile character. Keeping the paste below 27°C (80.6°F) is the key that unlocks the door to high-quality designations. You can dive deeper into these standards by reading about what is first cold-pressed olive oil in our dedicated guide.

The decisions a miller makes in these critical minutes define the oil's final personality. They can coax out greener, more herbaceous notes or aim for a softer, fruitier profile. It's a masterful blend of science and intuition, turning a simple fruit paste into the foundation of a world-class olive oil, now ready for the final, magical separation.

Separating Gold: The Magic of Cold Extraction

We now have our olive paste—a fragrant, vibrant mash of fruit, water, and oil. The moment of truth has arrived: separating the precious oil from everything else. The entire process of olive oil making pivots on this single step, and it is here that modern technology has completely redefined what is possible.

You have likely seen romantic images of old stone presses, with round, woven mats stacked high, slowly squeezing out the oil. This is where the term “first cold press” originated. While beautiful, the harsh reality was that this slow method exposed the delicate oil to its greatest enemy: oxygen. Every moment the paste sat in the open air, oxidation began its destructive work, degrading the flavor and destroying healthy polyphenols.

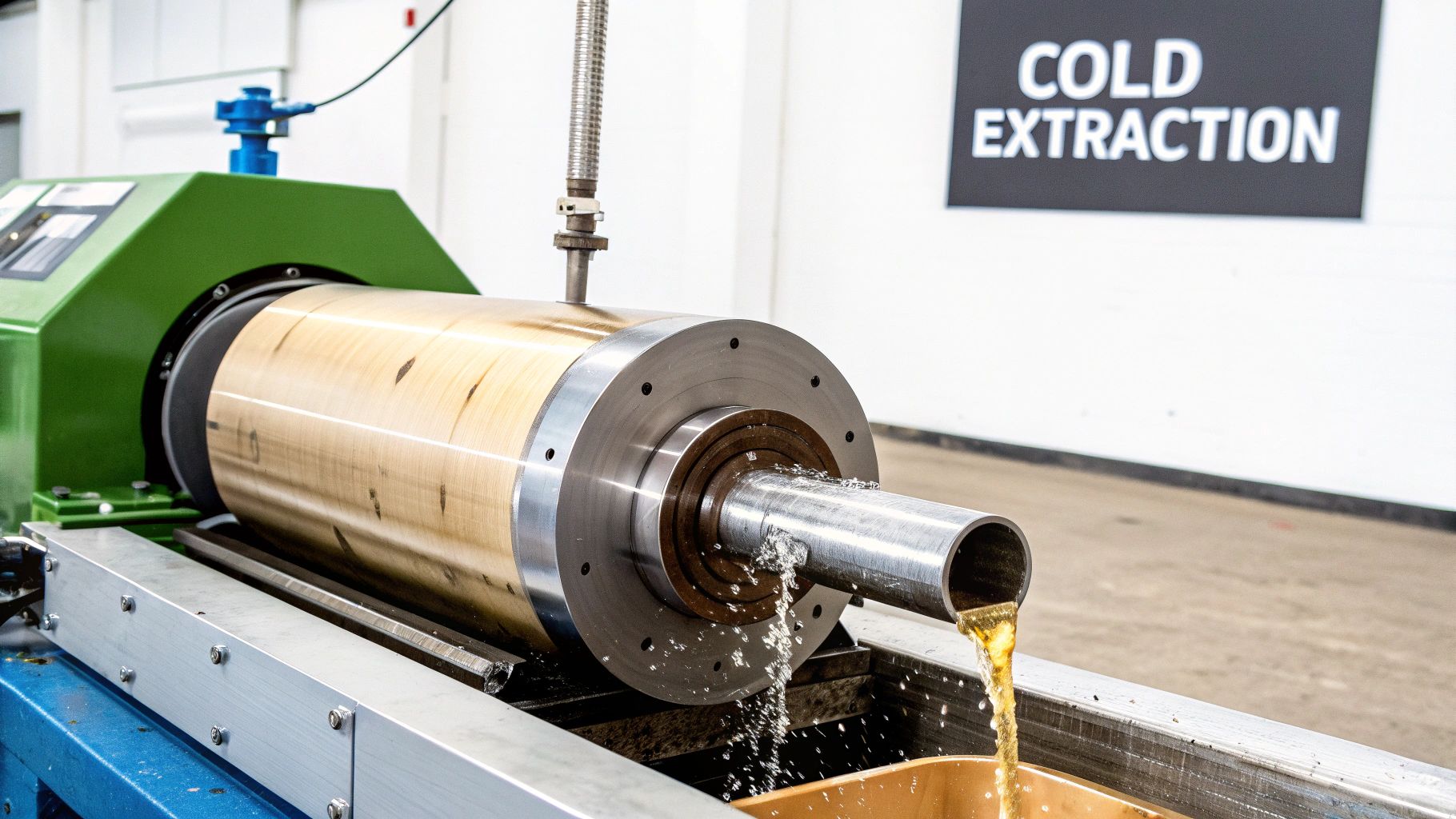

That is why today, the world’s finest olive oil producers have abandoned the press for a far superior tool: the centrifuge. This machine is the beating heart of modern “cold extraction.”

The Power of the Decanter

The olive paste is gently pumped into a horizontal centrifuge, known as a decanter. The easiest way to picture it is as a giant, high-tech salad spinner lying on its side. It spins at thousands of RPMs, generating incredible force to separate the paste’s components based on a simple principle: density.

Oil is lighter than water, correct? The centrifuge accelerates that natural separation by a factor of thousands. The heavier components—fruit solids (pomace) and water—are flung against the outer wall of the spinning chamber, while the lighter, purer olive oil collects in the center.

The centrifuge is the unsung hero of modern olive oil. It operates in a sealed, oxygen-free environment, shielding the oil from oxidation at its most vulnerable stage. This single innovation is arguably the greatest leap forward in quality the industry has ever witnessed.

This first separation is a marvel of engineering. In a continuous, efficient flow, a murky paste enters one end, and out the other come separate streams of solids, water, and a cloudy, brilliant green-gold oil. But the process is not quite complete.

Polishing the Liquid Gold

From the decanter, the oil often flows into a second, vertical centrifuge. Think of this machine as a final polisher. It spins even faster, zipping out the last microscopic bits of sediment and water that might still be suspended in the liquid.

This final spin gives the oil its dazzling clarity and sheen, preparing it for storage. Every part of this process is engineered to be swift and gentle, preserving all the fragile aromas and powerful antioxidants that define a truly great oil.

The most critical factor of all? Temperature. For an oil to earn the label "cold-extracted," the temperature of the paste must remain below 27°C (80.6°F). This isn't just a guideline; it is an ironclad rule for crafting true extra virgin olive oil. Any hotter, and you would essentially be cooking the oil, destroying the fresh, peppery, and fruity notes that are its signature. To dig deeper into this, you can learn more about what cold-pressed olive oil means.

This meticulous, temperature-controlled extraction is what makes an exceptional oil. It guarantees that the liquid gold flowing from the centrifuge is as pure, flavorful, and healthy as the fresh olives from which it came.

Olive Oil Extraction Methods: A Modern Comparison

To truly appreciate the quantum leap in quality, it helps to see the old and new methods side-by-side. The differences in control, efficiency, and the final product are like night and day.

| Feature | Traditional Press ('First Cold Press') | Modern Centrifugation ('Cold Extraction') |

|---|---|---|

| Oxygen Exposure | High. Paste is exposed to air for long periods. | Minimal. The system is sealed and enclosed. |

| Hygiene | Difficult. Fiber mats are hard to clean thoroughly. | Excellent. Stainless steel is easily sanitized. |

| Temperature Control | Inconsistent and difficult to regulate. | Precise. Temperature is monitored throughout. |

| Efficiency | Lower. Leaves a fair amount of oil in the pomace. | High. Extracts nearly all available oil. |

| Final Oil Quality | Prone to oxidation and defects. Shorter shelf life. | Higher purity, richer flavor, more polyphenols. |

| Process Speed | Very slow, batch-based process. | Fast and continuous. |

While the traditional press holds a certain romantic appeal, modern centrifugation is undeniably superior for producing the clean, vibrant, and healthy extra virgin olive oil that experts prize today.

Earning the Title: The Trial by Fire for Extra Virgin

Not every drop of oil that emerges from the centrifuge is worthy of the "extra virgin" crown. This is no mere marketing slogan; it is a legally protected designation, guarded by ruthlessly strict international standards. The journey to this title is a two-part trial, combining cold, hard science with the refined art of human perception.

The first gatekeeper is the laboratory, where the oil undergoes a battery of chemical tests to prove its purity and freshness. The most critical of these is the free fatty acidity (FFA) level. Think of this number as a direct report card on the quality of the fruit and the speed of production.

For an oil to even be considered for the extra virgin category, its FFA must be below 0.8%. A low FFA is a producer's badge of honor—it is irrefutable proof that the olives were healthy, harvested without bruising, and milled within hours. A higher number signals that something went terribly wrong. The fruit was likely overripe, damaged, or left to sit for too long, allowing decay to set in.

The Unforgiving Human Palate

If the oil survives the chemical gauntlet, it faces its second, and arguably tougher, challenge: a certified human sensory panel. No machine can replace the nuanced ability of a trained taster to detect the subtle flaws that science might miss. These experts are the ultimate guardians of the extra virgin standard.

The panel's job is twofold. First, they search for positive attributes—the three pillars of a great oil:

- Fruitiness: The aroma and flavor of fresh, healthy olives, which can range from green and grassy to ripe and buttery.

- Bitterness: A sharp, pleasant taste on the tongue, often a marker of fresh, early-harvest olives rich in antioxidants.

- Pungency: A peppery or spicy sensation in the back of the throat, another sign of healthy compounds like oleocanthal.

But more importantly, they hunt for defects. The presence of even a single flaw means instant disqualification. There is no middle ground.

To be crowned Extra Virgin, an oil must have zero defects and a discernible level of fruitiness. It is an absolute, pass-fail test. One misstep anywhere in the process, from a bruised olive to an overheated malaxer, and the oil gets demoted.

Common Defects That End the Dream

The sensory panel is trained to identify dozens of potential flaws, but a few appear with depressing regularity when things go wrong. These are not subtle imperfections; they are clear signs of a poorly made product.

Common Flaws:

- Fusty/Muddy Sediment: This defect arises from olives being piled up and stored for too long before milling, causing them to ferment without oxygen. It gives the oil an aroma reminiscent of sweaty socks or swampy vegetation.

- Rancid: This is the most common defect found in oil on store shelves. It's caused by oxidation from exposure to air, light, or heat and smells like old nuts, crayons, or stale oil.

- Winey-Vinegary: This fault occurs when olives begin to ferment with oxygen, creating acetic acid. The oil will have a sharp, sour smell like wine that has turned to vinegar.

The entire olive oil world moves to the Mediterranean's rhythm, but unpredictable weather can cause dramatic swings in output. Turkey, a rising powerhouse, illustrates this volatility well. In a recent peak year, its production hit 505,000 tons, which sent its olive oil exports soaring by 132%. This shows how quickly the global supply can shift, reinforcing why the rigorous standards for certified oils are so crucial for guaranteeing the flavor and health benefits consumers expect.

This demanding dual-gate system—chemistry and sensory analysis—is what makes the extra virgin designation so meaningful. It ensures that any oil bearing the name is not just chemically pure, but also aromatically and flavorfully perfect. It is, in the truest sense, an unadulterated fruit juice. To better understand these strict criteria, you can explore our guide on extra virgin olive oil certification.

Resting and Bottling: The Final Steps

The journey from fruit to liquid gold is not quite over. Fresh from the centrifuge, the oil is a vibrant, cloudy liquid, practically humming with the energy of its creation. But before it is ready for your kitchen, it must be protected, settled, and bottled with meticulous care. This is the final, critical line of defense for its quality.

The brand-new oil is immediately whisked away to massive, gleaming stainless steel tanks. These are not just holding vats; they are fortresses, housed in climate-controlled rooms designed to shield the oil from its three mortal enemies: oxygen, light, and heat. Any one of these can turn a perfect oil rancid in a surprisingly short time.

Here, in the cool, dark quiet, the oil is allowed to rest. This settling period, known as racking, is a gentle, natural clarification process. Over several weeks, any remaining microscopic bits of olive fruit and water—the very things that give the new oil its cloudy appearance—slowly succumb to gravity and settle at the bottom of the tank.

To Filter or Not To Filter

After racking, the producer faces a choice that splits the olive oil world: to filter or not. One path leads to a crystal-clear oil with a longer, more stable shelf life. Filtration removes the last of the fine sediment, ensuring the oil remains pristine in the bottle for months to come. This is the common choice for oils meant for wide distribution.

The other path is to leave the oil unfiltered. This rustic, intensely flavored oil is often called olio nuovo or "new oil." It's prized for its robust, hazy character, but it comes with a catch: you must use it quickly. The very sediment that gives it that unique personality will also cause it to spoil faster.

The final act of making olive oil is bottling, and it's done with almost surgical care. The main goal is to get the oil from the tank to the bottle with the absolute minimum exposure to its greatest enemy, oxygen.

The Final Seal of Quality

Master bottlers go to extraordinary lengths to protect their product. Many will flush the empty bottles with an inert gas, like nitrogen, just before filling. This simple step pushes out all the oxygen, creating a protective blanket for the oil. It is an expensive detail, but one that makes a world of difference in preserving freshness.

The choice of container is just as vital. You should never see a high-quality extra virgin olive oil in a clear glass bottle. Dark glass or opaque tins are non-negotiable, as they block the damaging UV light that accelerates rancidity.

Finally, a secure, tamper-proof seal and—most importantly—a harvest date are the final stamps of integrity. This date tells you exactly when the olives were picked and milled, giving you the ultimate assurance of freshness. It's the producer’s final promise, a guarantee that they have done everything possible to deliver the vibrant, living soul of their olives from their mill to your table.

Your Olive Oil Questions, Answered

As you dive into the world of olive oil, a few questions always seem to surface. Think of this as the final piece of the puzzle, connecting what you see on the bottle to the hard work that happened months earlier in a distant olive grove and mill.

Getting these details right will help you move beyond being just a consumer to becoming someone who truly understands what makes a great olive oil.

Does the Color of Olive Oil Indicate Its Quality?

This is perhaps the biggest myth in the olive oil world—that a deep, dark green oil is automatically superior. While a vibrant green can look beautiful, color tells you almost nothing about the oil's quality. The real story behind the hue is all about chlorophyll and when the olives were picked.

- Early-harvest oils, made from green, less-ripe olives, are packed with chlorophyll. This gives them that intense green color, along with a peppery, sometimes bitter, flavor profile.

- Late-harvest oils come from olives that have ripened and darkened on the tree. They have less chlorophyll, resulting in a more golden-yellow color and a softer, buttery taste.

Both can be exceptional extra virgin olive oils. In fact, professional tasters use special blue glasses to evaluate oils, specifically so that color cannot influence their judgment. The true measures of quality are revealed in its aroma and taste: fresh, fruity scents and a balanced flavor free of any off-putting defects.

What Does "Cold Extracted" Really Mean?

You see "cold-pressed" or "cold-extracted" on nearly every label of high-quality oil. It sounds impressive, but what does it actually mean? It is a guarantee that during the entire milling process, the olive paste was kept below 27°C (80.6°F).

That specific number is crucial. It is the tipping point for preserving everything good inside the olive.

Once the temperature climbs higher, the oil's delicate aromas begin to evaporate and its healthy polyphenol antioxidants start to break down. A producer could certainly get more oil by cranking up the heat, but they would be sacrificing the very soul of the oil—its vibrant flavor, fresh scent, and powerful health benefits.

So when you see "cold extraction," you know the producer chose quality over quantity. It is an essential standard for making authentic extra virgin olive oil.

How Long Does Olive Oil Last Once Opened?

Here’s a key difference from wine: olive oil does not get better with age. It is a fresh fruit juice, and its quality is at its absolute peak right after it’s milled. The clock starts ticking the moment you break the seal and expose it to its number one enemy: oxygen.

As a general rule, try to use an open bottle of extra virgin olive oil within 30 to 60 days. It won’t go bad in a way that will make you sick, but its bright, fruity notes will fade, and it will eventually become rancid. A rancid oil not only tastes stale (think old crayons or nuts) but has also lost its antioxidant punch.

To give your oil the best life possible, store it in a cool, dark place and always seal the cap tightly. And please, never keep it next to the stove—the heat is a fast track to ruin.

What Is the Difference Between Filtered and Unfiltered Oil?

Right after the oil is extracted, the producer has a choice: filter it or leave it cloudy. This decision creates two very different styles of oil.

| Feature | Filtered Olive Oil | Unfiltered Olive Oil (Olio Nuovo) |

|---|---|---|

| Appearance | Bright, clear, and translucent. | Hazy or cloudy from tiny bits of suspended olive fruit. |

| Flavor Profile | Clean, crisp, and well-defined flavors. | Bolder, more intense, and sometimes a bit rustic. |

| Shelf Life | More stable, lasting 18-24 months from harvest. | Very short; best enjoyed within 3-6 months. |

| Best Use | A fantastic all-rounder for everything from finishing to cooking. | A special treat for drizzling and finishing to celebrate its fresh character. |

Filtering simply removes the last microscopic particles of olive and water, which makes the oil much more stable and gives it a longer shelf life. Unfiltered oil, often sold as olio nuovo ("new oil") right after harvest, is a seasonal delight meant to be savored quickly before those leftover solids cause it to spoil. Neither style is inherently better; it all comes down to personal preference.

At Learn Olive Oil, we believe that understanding the journey of this liquid gold deepens your appreciation and empowers you to make better choices. From the grove to your table, every step matters, and now you have the knowledge to taste the difference.

Start your journey and discover a world of flavor at https://learnoliveoil.com.

Leave a comment