Have you ever uncorked a bottle of exceptional olive oil and wondered, just for a moment, how something so vibrant and alive could come from a simple fruit? The journey from a bitter olive on the branch to that peppery, liquid gold in your kitchen is a story of craft, speed, and secrets passed down through generations.

At its heart, the process is pure alchemy: fresh olives are crushed into a thick, fragrant paste. This paste is then gently coaxed—a slow, hypnotic process called malaxation—before a powerful centrifuge spins the pure oil away from the water and solids.

This isn't just manufacturing. It’s a race against time, an art form where ancient tradition shakes hands with modern science. Every decision, from the second the olive is picked to the precise temperature inside the mill, leaves its indelible signature on the final flavor, aroma, and fire of the oil. This guide will pull back the curtain on this entire mesmerizing process, revealing what separates a world-class extra virgin olive oil from everything else on the shelf.

To truly savor the difference, it helps to know what you're tasting. Before we dive in, a quick detour into understanding the five basic tastes in food will give you the foundation to recognize the complex symphony of flavors that make a truly great olive oil sing.

From Harvest to Bottle

The entire operation is a frantic, high-stakes sprint against the clock. Why the rush? Because freshness is everything. The moment an olive is picked, its delicate compounds—the very source of its health benefits and legendary taste—begin to degrade. The goal is to capture them at their absolute peak.

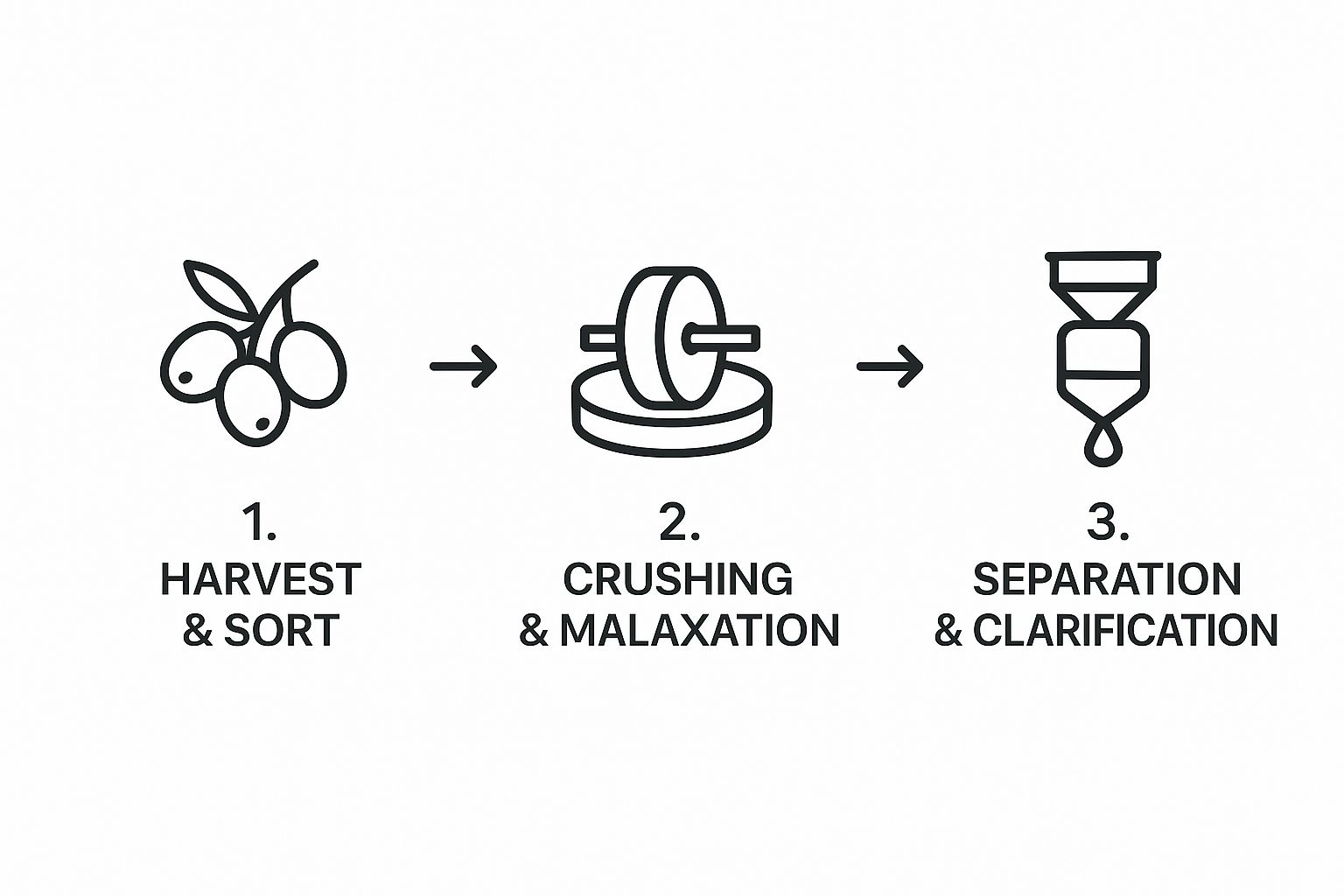

The flowchart above reveals the three critical acts in this drama:

- Harvesting and Sorting: Plucking the fruit at its moment of perfect ripeness and ruthlessly weeding out every leaf and twig.

- Crushing and Malaxation: Grinding the olives into a fragrant paste, then gently stirring it to persuade tiny oil droplets to merge.

- Separation and Storage: Unleashing the power of a centrifuge to spin the pure, liquid gold free from the rest of the olive matter.

The chasm between an ordinary oil and an extraordinary one is carved out in the tiny, obsessive details of these steps. A closer look at the complete https://learnoliveoil.com/olive-oil-manufacturing-process reveals how master producers manipulate variables like temperature and time to craft their liquid masterpieces.

Here's a quick look at the modern extraction battlefield.

Key Stages in Modern Olive Oil Extraction

| Stage | Objective | Method |

|---|---|---|

| Harvest & Cleaning | Gather impeccable olives and banish leaves, twigs, and dirt that cause off-flavors. | Mechanical shakers or careful hand-picking, followed by washing and air-blowing. |

| Crushing | Shatter the olive's cellular walls to set the imprisoned oil free. | Hammer mills or stone grinders pulverize whole olives into a thick, uniform paste. |

| Malaxation | Gently persuade tiny oil droplets to coalesce into larger, more easily captured drops. | The paste is slowly churned in a temperature-controlled trough for 20-40 minutes. |

| Extraction | Separate the oil from the solid pomace and vegetable water. | A decanter centrifuge spins the paste at incredible speeds, separating components by density. |

| Separation | Polish the oil by removing any lingering water and fine sediment. | A final vertical centrifuge spins the oil one last time to guarantee absolute purity. |

Each of these stages is a battlefield where quality is either won or lost.

The secret to a phenomenal olive oil isn't hidden in a single, magical step. It lies in the seamless, swift, and fanatically careful execution of the entire process. A single delay, a single miscalculation, can shatter the delicate balance of flavor and nutrients forever.

The Critical Role Of The Olive Harvest

If you think the story of a great olive oil begins inside a bustling mill, with its giant stone wheels and gleaming steel presses, you’re missing the most important chapter. The true character of the oil—its flavor, its peppery fire, its very soul—is decided in the grove, at the precise moment an olive is plucked from its branch.

The harvest isn’t just another task on a checklist. For the true artisans of olive oil, it is the single most defining moment.

Here, the producer makes their most crucial gamble: when to pick. Do they harvest early, when the olives are a vibrant, hard green? This choice yields a bold, pungent oil, blazing with healthy polyphenols but offering a stingy amount of liquid. Or do they wait, letting the fruit ripen to a deep purplish-black? This delivers a much larger bounty of smoother, buttery oil, but at the cost of intensity and shelf life.

There is no single "right" answer. But this one decision fundamentally dictates the personality of the oil that will end up in your bottle.

Protecting The Fruit At All Costs

Once that perfect moment arrives, the next battle begins: getting the olives from the tree to the mill without a single scratch. An olive’s skin is its armor. The instant it’s broken, oxidation—the mortal enemy of freshness—launches its attack, and the countdown to defects and off-flavors begins.

To keep the fruit flawless, growers rely on a few time-honored methods:

- Hand-Raking: The classic, gentle approach. Workers use small, handheld rakes to tenderly comb olives from the branches onto vast nets spread below. It is painstaking work, but it is the surest way to prevent bruising.

- Mechanical Shakers: In larger groves, you’ll see powerful shakers clamp onto a tree’s trunk and vibrate it fiercely, raining olives down. It is astonishingly efficient, but demands a skilled operator to avoid harming the fruit or the tree.

No matter the method, the mission is identical: treat the fruit like the treasure it is. The best producers are haunted by the ticking clock. They race their harvest to the mill within 24 hours, and the truly fanatical aim for less than 12. This desperate sprint against time is a non-negotiable part of the craft.

If you’re fascinated by how these first, critical decisions make or break an oil, our in-depth guide to olive oil harvesting lays bare the secrets of these crucial first hours.

The most skilled olive oil producers know their job is not to create flavor in the mill, but to preserve the pristine quality that was cultivated in the grove. The harvest is their one chance to capture that perfection.

2. Crushing Olives Into A Fragrant Paste

The moment those pristine olives arrive at the mill, the race against oxidation intensifies. Here, the first, most dramatic transformation begins: crushing the entire fruit—pit, flesh, and all—into a thick, astonishingly fragrant paste. This is the precise instant the oil, held captive in the olive's microscopic cells, is finally liberated.

This is a foundational step, and the method chosen here leaves an indelible fingerprint on the final oil. The machinery isn't just about efficiency; it's a strategic decision that directly shapes the flavor, aroma, and even the chemical makeup of what ends up in your bottle.

While the tools are now space-age, the principle is ancient. Olives were once pounded with mallets or ground under colossal stone wheels. Today, it's a highly refined, mechanized process. After a thorough washing, the olives are fed into industrial crushers. To see how this age-old practice has evolved alongside market forces, you can find more details about the reasons behind olive oil price shifts and the technologies that drive them.

The Old-World Stone Mill

The stone mill is the romantic image most people conjure: two massive granite wheels, weighing several tons, slowly revolving in a basin, grinding the olives into a uniform paste.

This method is gentle. It generates very little heat, which is fantastic for preserving delicate aromas. The downside? It’s slow and exposes the paste to more oxygen, which can sometimes lead to a less stable oil with a shorter shelf life. Today, it’s a rare sight, mostly used by artisanal producers pursuing a specific, traditional style.

The Modern Steel Hammer Mill

The undisputed champion of the modern mill is the steel hammer mill. This machine uses rotating metal hammers to smash the olives at breathtaking speed against a perforated screen. It’s incredibly fast, ruthlessly efficient, and can process tons of olives in an hour.

The true genius of the hammer mill is the control it offers. The miller can swap out screens with different-sized holes to dial in the exact texture of the paste—finer for a more bitter and pungent oil, coarser for something softer and milder.

The real artistry in crushing isn't about brute force. It's about achieving the perfect rupture of the olive's cells without generating the destructive enemy: heat. Too much warmth obliterates the valuable polyphenols and delicate aromas that define a premium extra virgin olive oil.

Ultimately, the choice between stone and steel comes down to the producer’s philosophy and the specific character they want to coax from their oil.

- Stone Mill: Creates a paste that often yields a sweeter, more delicate oil, but one that may be prone to faster oxidation.

- Hammer Mill: Offers surgical precision and speed, leading to oils that are typically more robust, pungent, and rich in antioxidants.

Regardless of the tool, the goal is always the same: to create a perfect, uniform paste that’s ready for the next crucial step in its journey to becoming liquid gold.

Mastering Malaxation To Release The Oil

After the violent, fragrant chaos of crushing, the olive paste enters a stage that’s all about patience and finesse. This crucial step is called malaxation, a term that sounds technical but is beautifully simple in practice. Picture that thick, green paste being gently and continuously folded over itself in a large, temperature-controlled trough.

It’s a slow, hypnotic process that seems almost too gentle to be doing anything important. But don't be fooled. This isn't just mixing. This is where a skilled miller coaxes the oil from the paste. The slow, steady churning encourages all those tiny, microscopic oil droplets liberated during crushing to find each other, connect, and coalesce into larger, more substantial drops.

Without this step, separating the oil later would be like trying to squeeze water from a barely damp sponge—frustrating and wildly inefficient. Malaxation makes the oil available, preparing it for a clean, easy extraction. It's the artful science behind how oil is extracted from olives in the most effective way.

The Delicate Balance Of Time And Temperature

The malaxation process is a masterclass in control, where two variables reign supreme: time and temperature. Get them right, and you’re on your way to a masterpiece. Get them wrong, and you can ruin an entire batch in minutes.

This gentle kneading usually lasts between 20 and 40 minutes. It’s a precise window, long enough for the oil droplets to merge but short enough to prevent overexposure to air.

Temperature is even more critical. To earn the coveted "cold-pressed" designation, the paste must remain below 27°C (80.6°F). A little warmth helps the oil flow and combine, but too much heat is the enemy. It triggers rapid oxidation, incinerating the delicate aromas and destroying the healthy polyphenols that give great olive oil its signature peppery kick and antioxidant power.

This is where a master miller earns their reputation. They don’t just set a timer; they read the paste. They know from sight, smell, and even touch when the oil droplets have formed perfectly, ready for the next stage. It's an intuition built over years of experience.

How Malaxation Defines The Final Oil

The decisions made during malaxation directly shape the final product's personality. The miller is essentially fine-tuning the oil's sensory profile right here in the trough.

- Shorter Malaxation: This tends to produce a more pungent, bitter, and robust oil. It preserves more of the raw, green characteristics of the olive but might result in a slightly lower yield.

- Longer Malaxation: This often leads to a milder, more buttery oil. While this can increase the total oil extracted, it also raises the risk of oxidation, potentially introducing flavor defects if the paste is exposed to oxygen for too long.

This stage is a perfect example of the compromises inherent in olive oil production. Pushing for maximum yield can come at the cost of flavor complexity and shelf life. For those interested in the finer points of this stage, our complete guide to the olive oil extraction process offers a much deeper dive.

Ultimately, it’s this carefully managed kneading that transforms a simple olive paste into a canvas, ready for the final separation of its liquid gold.

How Centrifuges Separate The Liquid Gold

After the patient, watchful work of malaxation, the olive paste arrives at its moment of truth. This is where the pure, liquid gold is finally liberated from the water and solids. While many of us still picture an old-fashioned stone press, the real hero in a modern mill is the decanter centrifuge—a marvel of engineering that performs the separation with astonishing speed and precision.

Think of it as a supercharged, industrial-grade salad spinner. The paste is piped into a long, horizontal drum that spins at thousands of RPMs. This ferocious centrifugal force accomplishes in seconds what would take gravity days to do: it sorts everything in the paste by its weight.

The physics are beautifully simple. The heaviest components—the solid bits of skin, pulp, and pit we call pomace—are slammed against the outer wall. The vegetable water, which is lighter than the solids but heavier than the oil, forms a layer just inside that. And finally, the lightest, most precious element of all, the olive oil, gathers right at the very center, shimmering and ready to be collected.

Two-Phase Versus Three-Phase Separation

Not all decanter centrifuges are built the same. Millers face a critical choice between two primary systems, and their decision has a profound impact on the oil's final character.

A three-phase centrifuge does exactly what its name suggests, separating the paste into three distinct outputs:

- Oil: The liquid gold.

- Water: A separate stream of vegetation water.

- Pomace: The semi-dry solid waste left behind.

A two-phase centrifuge, however, produces only two streams: oil and a very wet pomace that still contains all the vegetation water. This might sound less efficient, but many elite producers swear by this method.

Why? Because many of the water-soluble polyphenols—those powerful antioxidants responsible for a great oil's peppery kick and health benefits—remain in contact with the oil for a bit longer. The result is often a more robust, flavorful, and nutrient-dense oil.

This ability to fine-tune the extraction is central to the European Union's capacity for producing world-class olive oil. You can find more details about the EU olive oil market and production techniques on certifiedorigins.com, where these methods are key to preserving quality while maximizing yield.

The choice between two-phase and three-phase extraction isn't just a technical detail—it's a philosophical one. It’s a trade-off between maximizing yield and preserving the highest possible concentration of flavor and antioxidants.

The Final Polish

But the journey isn't over yet. The oil emerging from the decanter is mostly pure, but it can still contain microscopic particles of fruit or water. If left behind, these impurities can cause the oil to spoil over time.

To guarantee a brilliant, stable, and flawless product, the oil often gets one last treatment in a vertical centrifuge. This final "polishing" step spins the oil again at an even higher speed, clarifying it completely and removing the very last trace of impurity.

What emerges is the pristine, luminous liquid gold that’s finally ready for storage and bottling. It’s crucial to note that this entire process is done without heat, a core principle you can explore further in our article on what is cold-pressed olive oil.

The Economics Driving Olive Oil Production

Behind the romance of ancient groves and artisanal traditions, olive oil production is a cutthroat business. The journey from tree to table is guided as much by economics as by culinary art, and the relentless pressure of the bottom line shapes every decision made in the mill.

For any producer, the extraction process is where the numbers get real. Even a fractional increase in the amount of oil extracted from a ton of olives—achieved with a new centrifuge or by perfecting the malaxation time—can translate into thousands of dollars by season's end. This is why millers are obsessed with efficiency.

The drive for better technology isn't just about making better oil; it's a desperate fight for survival in a fiercely competitive global market.

The Global Marketplace

The olive oil market is a colossal global arena where producers constantly hunt for a competitive edge. The market was valued at around $13.58 billion USD in 2021 and is projected to surge to $15.64 billion USD by 2025. This explosive growth, fueled by health-conscious consumers, means producers must adopt the most efficient extraction methods just to stay in the game.

You can dive deeper into these market trends on cognitivemarketresearch.com.

This financial reality forces difficult choices. Should a miller invest a fortune in a top-of-the-line two-phase decanter? It may produce less oil, but that oil will be packed with valuable polyphenols and command a premium price. Or is it smarter to stick with an older three-phase system that maximizes volume for the bulk market? These are not just technical questions; they are critical business strategies.

In the world of olive oil, there's a constant war between quality and quantity. The producers who don't just survive, but thrive, are the ones who master this balancing act, creating a product that wins awards while also paying the bills.

Tools for agricultural yield and profit estimation help put the immense economic challenges producers face into perspective. At the end of the day, every advance in milling technology is an investment in keeping this ancient industry alive and profitable, ensuring that magnificent, high-quality olive oil continues to find its way to our tables.

Your Olive Oil Questions, Answered

After this journey from the tree to the bottle, you might have a few questions. That's a good thing. Let's tackle some of the most common curiosities people have about how this liquid gold is really made.

Think of this as the final key that unlocks the puzzle, connecting the dots between the extraction process, the different grades you see on the shelf, and what truly makes a bottle of oil worth its price.

What Does "Extra Virgin" Actually Mean?

This is the most important question of all, and the answer is far more demanding than most people realize. For an oil to earn the coveted "extra virgin" title, it must pass two ironclad tests.

First, the oil must be extracted using only mechanical means—no chemicals, no high heat, just the pure, physical pressing and spinning of the olives. Second, it must undergo a rigorous chemical analysis and then be judged by a certified tasting panel. This panel ensures the oil has zero flavor defects and exhibits the fresh, fruity characteristics of a perfect olive.

In short, "extra virgin" is a guarantee of both purity in its production and perfection in its flavor. It is the highest grade an olive oil can possibly achieve, representing the purest expression of the fruit.

Is All Olive Oil Made The Same Way?

Absolutely not. While extra virgin olive oil must adhere to the pristine cold-mechanical process we've explored, the story is dramatically different for the lower grades.

- Virgin Olive Oil: This is also extracted mechanically, but it's permitted to have minor flavor defects and a slightly higher acidity level. It's a clear step down from EVOO.

- Refined Olive Oil: This is where things take an industrial turn. This oil has been chemically treated to strip away unpleasant flavors and other defects. The result is a colorless, odorless oil that has also been stripped of the powerful antioxidants found in extra virgin.

- Pomace Oil: This is the bottom of the barrel, extracted from the leftover olive paste (the pomace) using chemical solvents and high heat. You do not want this on your food.

Understanding this hierarchy is a game-changer. It empowers you to make smarter choices, whether you're searing a steak or drizzling a finishing oil over pasta. For more on this, our guide on olive oil uses for cooking offers fantastic, practical advice. It shows precisely why investing in a true EVOO for finishing a dish is always worth it.

At Learn Olive Oil, we believe that understanding the journey from grove to table deepens your appreciation for this liquid gold. We're here to guide you with expert insights and clear advice.

Discover the world of premium olive oil at https://learnoliveoil.com.

Leave a comment