Making olive oil is the art of transforming a freshly-picked olive into liquid gold. It's a craft that demands more than just machinery; it requires a blend of ancient wisdom and modern precision. In this world, timing and technique are not just important—they are everything. They are the invisible hands that shape a simple fruit into a culinary masterpiece, deciding its final flavor, its intoxicating aroma, and its soul-stirring quality.

The Hidden Craft in Every Drop of Olive Oil

Before you ever lay hands on a press, you must grasp one profound secret: you don't create great olive oil. You preserve it. The potential for a world-class oil is already locked inside the fruit, a gift from the sun and soil. Your entire job, from harvest to bottle, is to unlock that potential without spilling a single drop of its perfection.

This guide isn’t a sterile, mechanical checklist. It is an invitation into the artisan’s world—a world where every single choice, no matter how small, echoes in the final taste.

We will pull back the curtain on this hidden craft, showing you how every variable—from the blush on the olive’s skin to the precise temperature of the paste—writes a different chapter in the story of your oil. Forget the factory floor; this is about understanding the very soul of the olive.

The Four Pillars of Quality Olive Oil

World-class olive oil never happens by accident. It is the direct result of a relentless, almost fanatical, devotion to four foundational pillars. Get just one of them wrong, and the entire structure of quality can come crashing down.

Here are the non-negotiable principles that separate the merely good from the truly magnificent.

| Pillar | Why It Is an Unbreakable Rule | The Critical Action You Must Take |

|---|---|---|

| Impeccable Fruit | Defects are born in the orchard. A bruised or overripe olive is a tainted olive. | Harvest only pristine, healthy fruit at its absolute peak of ripeness. |

| Absolute Cleanliness | A single leaf or twig can introduce a woody taint that ruins an entire batch. | Meticulously clean every piece of equipment, from harvest bins to the mill. |

| Sense of Urgency | Oxidation, the mortal enemy of freshness, begins the second an olive leaves the tree. | Mill your olives within 24 hours of harvest—and preferably, much sooner. |

| Cold Extraction | Heat boosts yield but murders the delicate aromas and healthy antioxidants. | Keep the olive paste below 27°C (80.6°F) throughout the entire process. |

Mastering these four pillars isn't just a suggestion; it is the price of entry into the world of exceptional olive oil.

The most sophisticated mill in the world cannot conjure a phenomenal oil from mediocre olives. The true art lies in preserving the perfect quality nature has already provided.

This guide will walk you through each stage, not as a rigid set of rules, but as a series of crucial moments. Every step is a chance to either protect the oil’s inherent character or diminish it. Understanding this is what separates the pretenders from the masters.

Pinpointing the Perfect Harvest Moment

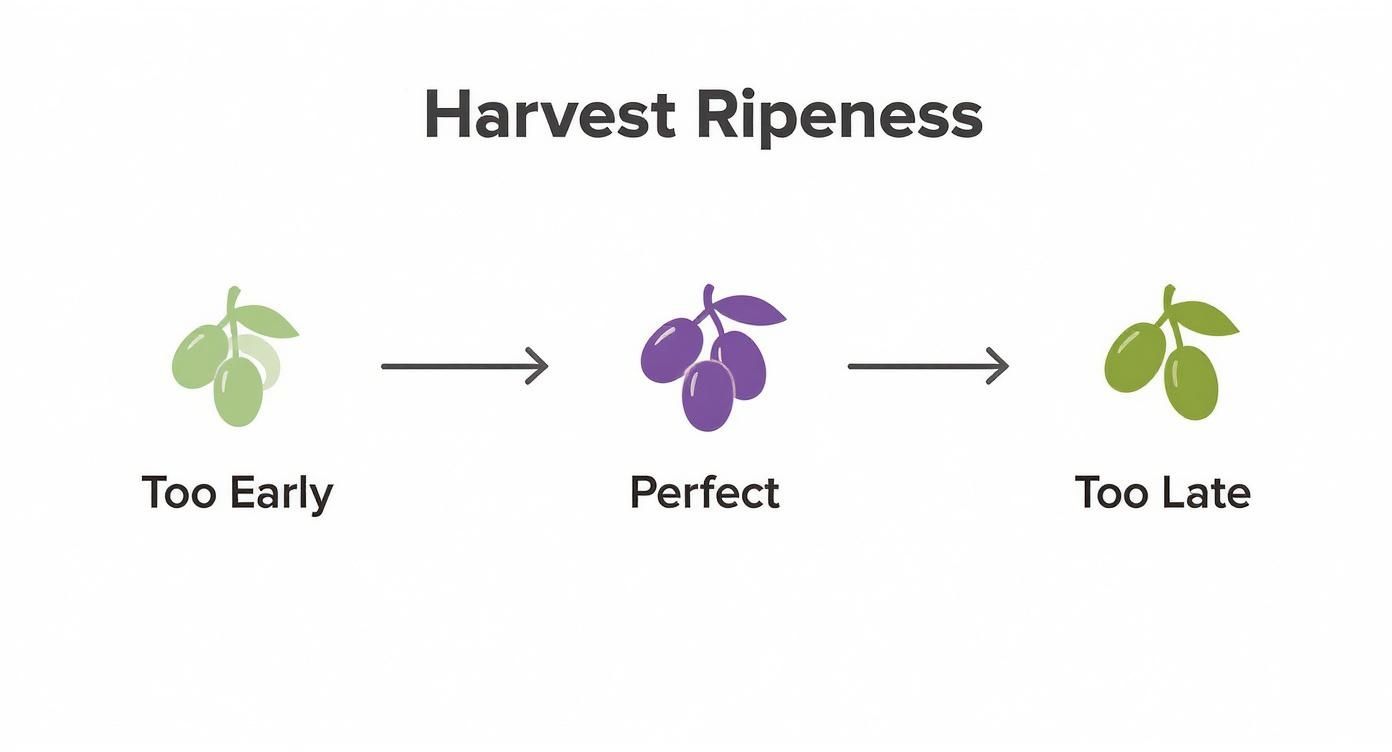

The entire destiny of your olive oil—its peppery fire, its fruity perfume, its very soul—is decided in a fleeting window of just a few days. Harvest a week too early, and you get an aggressive, unbalanced oil that screams instead of sings. Wait a week too long, and that vibrant potential collapses into a flat, greasy liquid with no life. Making olive oil isn't just a process; it's an act of perfect timing.

Think of this as your field guide to reading the secret language of the olive. Forget simple color charts; they only whisper a fraction of the truth. True ripeness is a multi-sensory code an artisan learns to see, to feel, and even to smell on the breeze.

Beyond Just Color

The journey from green to black is called veraison, but it's not a uniform march to the finish line. I’ve discovered that an olive that is 50% straw-green and 50% violet-black is often the sweet spot. At this magical stage, the fruit has not only reached its peak oil content but, more importantly, its highest concentration of polyphenols—the powerful antioxidants that give premium oil its peppery kick and its remarkable longevity.

But you cannot judge an olive by its color alone. You must learn its feel. A perfectly ripe olive for pressing has a certain give, a gentle softness that yields to pressure without being mushy. It’s the difference between a firm, vibrant grape and one that has surrendered to time. This is a skill developed over seasons, much like how one masters the planting, care, and harvesting fruit trees by tuning into the plant's quiet rhythms.

The Two Paths of Harvesting

Once you’ve identified that perfect moment, you face a critical decision. How will you get the fruit from branch to bin? The method you choose has an immediate, irreversible impact on the oil's final quality.

- Hand-Picking: This is the artisan's choice, without question. Harvesters use small, rake-like tools to gently coax the olives from their branches onto nets spread below. It's painstaking, slow, and expensive, but it offers unparalleled control, ensuring almost zero bruising.

- Mechanical Shaking: For larger groves, mechanical shakers are the pragmatic solution. They clamp onto the trunk and vibrate the tree, causing the fruit to rain down. While brutally efficient, this method can be harsh, risking damage to both the olive and the tree if not operated by a skilled hand.

Whichever path you choose, the golden rule is absolute: prevent bruising at all costs. A bruised olive is a wounded olive. The moment its skin breaks, oxidation begins, and enzymatic reactions start creating foul, off-flavors. This is the first step on the road to rancidity.

Every bruise on an olive is a tiny tear in the fabric of your final oil's quality. A pristine harvest is the only foundation upon which a world-class olive oil can be built.

Preserving the Polyphenols

The entire harvest is a race against time to preserve those precious polyphenols. These compounds are the guardians of both the oil's health benefits and its flavor profile. They are the source of that desirable bitterness (amaro) and pungency (piccante) that connoisseurs crave.

A gentle, swift harvest is your shield, protecting these delicate compounds from harm. For those eager to master this critical stage, our detailed guide on olive oil harvesting offers deeper insights and varietal-specific advice. The goal is simple but demanding: move the olives from tree to mill with a sense of controlled urgency, treating them not as a commodity but as the fragile vessels of liquid gold they are.

The Race From Branch to Mill

The moment an olive is plucked from its branch, an invisible clock starts ticking. It’s a frantic, irreversible countdown against oxidation. Every hour that passes is an open invitation for defects to creep in, slowly stealing the oil's potential for greatness.

This isn’t just about moving fruit; it’s a sequence of precise, critical actions designed to deliver the olives to the mill in a state of absolute perfection.

The timing of the harvest, which we just covered, is the first and most crucial decision in this race. It sets the stage for everything that follows.

As you can see, that "perfect" harvest window is dangerously narrow. It dictates the entire balance of flavors and polyphenols before a single olive even sees the inside of a mill.

The Critical First Steps: Sorting and Washing

Once at the mill, the olives face their first test. They are gently tumbled onto sorting tables where powerful fans blow away any stray leaves, twigs, and other field debris. This isn't just about housekeeping. A single stray leaf can introduce a woody, astringent bitterness that can taint an entire batch.

After this "de-leafing," the olives get a quick, cold-water bath. This removes any lingering dust or soil. Speed is critical—olives are porous and can absorb water, which complicates extraction and can dilute the quality of the final product.

From Fruit to Paste: The Crusher

Cleaned and ready, the olives now meet the crusher. In this violent, transformative moment, the fruit's cellular structure is ruptured, releasing the microscopic droplets of oil held within. The machine you use here has a profound impact on the oil's final character.

There are two main schools of thought:

- Stone Mills: This is the romantic image of old-world olive oil making—two massive granite wheels slowly grinding olives into a coarse paste. The method is gentle and tends to produce a softer, sweeter oil. But it is also slow and exposes the paste to more oxygen, a risk most modern producers refuse to take.

- Hammer Mills: This is the modern standard. A hammer mill uses high-speed, rotating metal hammers to pulverize the olives against a screen. It's incredibly fast and efficient. More importantly, by changing the screen size and hammer speed, a skilled miller can craft vastly different flavor profiles—from delicate and buttery to intensely pungent and green.

The choice is a deliberate one. A hammer mill gives the artisan far more control, allowing them to tailor the process to a specific olive variety and the exact style of oil they aim to create.

The crusher doesn't just break the olive; it begins to define its voice. A slow grind whispers, while a fast pulverization shouts. The miller's job is to choose the right tone for the story the oil is meant to tell.

This obsession with precision is why the olive oil manufacturing process is so meticulously managed by global leaders. Production is concentrated in just a few countries, with Spain and Italy alone producing over one million tons annually. A staggering 75% of exported volumes from these regions are extra virgin, a testament to their mastery of these high-quality methods.

Malaxation: The Heart of Flavor Development

From the crusher, the olive paste is pumped into a malaxer—a long, stainless-steel trough where spiral blades slowly churn. This may be the most misunderstood—and most crucial—step of them all.

For the next 20 to 40 minutes, the paste is gently and continuously kneaded. This is not wasted time. During malaxation, the tiny oil droplets released during crushing are coaxed into pooling together, forming larger drops that will be easier to separate later.

But something far more magical is happening. A delicate enzymatic dance is unfolding, developing the oil’s complex aromas and signature flavors. Here, temperature is everything. It must be kept below 27°C (80.6°F) to be considered true "cold pressing." A few degrees higher might increase your yield, but at a terrible cost: the volatile, aromatic compounds that give an oil its personality are burned off, lost forever. This hypnotic, patient kneading transforms a simple olive paste into the soul of a true extra virgin olive oil.

Separating Gold From Pulp

After the slow, deliberate kneading of malaxation, the olive paste is finally ready to surrender its treasure. This is the moment of truth, where the liquid gold is coaxed out from the solids and vegetable water. How you handle this step defines the oil's final purity and character.

For centuries, the iconic image of this process was the hydraulic press. You've seen the pictures: stacks of round, woven mats (fiscoli) slathered with olive paste, then squeezed under immense pressure until oil trickles out. It’s undeniably romantic.

Unfortunately, it’s also a minefield for quality. Those porous mats are nearly impossible to clean perfectly, often holding onto old, rancid residues that can contaminate a fresh batch. Worse, the process exposes the oil to a flood of oxygen, kicking off the very oxidation you've fought so hard to prevent. For these reasons, you'll rarely see a traditional press used by producers of top-tier extra virgin olive oil today.

The Modern Heart of the Mill

Enter the decanter centrifuge. This gleaming stainless-steel machine is the heart of any modern olive mill. It’s a technological marvel that spins the olive paste at thousands of RPMs, using powerful centrifugal force to separate everything by density.

Inside the spinning drum, the heaviest material—the solid pulp, or pomace—is flung to the outside wall. The vegetable water forms a layer just inside that. And the lightest of all, the precious oil, collects right in the center. It’s a clean, fast, and completely sealed process that keeps oxygen out, preserving the oil's fragile aromas and polyphenols.

The precision needed here is incredible, which is why many mills rely on advanced industrial automation systems to manage the extraction. The choice of centrifuge system itself has a huge impact on the final product.

Two-Phase vs. Three-Phase Decanters

The choice between a two-phase or three-phase system is one of the most significant decisions a miller makes. It's a classic debate that pits yield against quality and environmental impact.

-

Three-Phase System: This was the older standard. It works by adding water to the paste to make separation easier. The centrifuge then spits out three things: oil, water, and pomace. While effective, it uses a lot of fresh water and, more importantly, many of the water-soluble polyphenols—the good stuff—get washed away, stripping the oil of its character.

-

Two-Phase System: This is the modern, quality-focused choice. It separates the paste into just two outputs: oil and a wet pomace (which holds both solids and water). Because no extra water is added, more of those vital, peppery polyphenols stay right where you want them: in the oil. The result is almost always a more robust, flavorful, and healthful product.

The leap from a three-phase to a two-phase decanter represents a fundamental shift in philosophy—from prioritizing quantity to preserving inherent quality. It’s a choice to keep the very soul of the olive intact.

This commitment to quality-driven technology is central to the global olive oil industry. Spain, the world leader, produced an estimated 1.42 million tons in the 2024/25 season, which is about 40% of the world's total supply. That kind of dominance is built on the efficiency and quality control that modern extraction provides.

The centrifuge is where the potential you unlocked during malaxation is either captured or lost. For a deeper dive, our complete breakdown of the olive oil extraction process covers these technologies in more detail. In this final, forceful separation, the vibrant, green-gold liquid is finally born.

Protecting Your Liquid Gold After the Press

The centrifuge spins its last rotation, and there it is: a stream of vibrant, almost electric-green liquid filling the tank. It is a moment of triumph. But the truth is, this newborn olive oil is at its most vulnerable. It's a living product, bursting with volatile aromas and potent antioxidants, and your job has just shifted from extraction to preservation.

Every step from here on out is about defending this liquid gold from its mortal enemies.

Even after the main decanter does its work, the oil isn't perfectly pure. It still holds microscopic particles of olive flesh and tiny droplets of water. Left alone, these impurities will settle at the bottom of the tank, creating a sludge that begins to ferment. This process causes the awful "muddy sediment" defect that can ruin an otherwise perfect oil.

To prevent this, the oil needs a final polishing. This is usually done with a vertical plate centrifuge, which spins the oil one last time. Its series of conical discs gently pulls out these last stubborn remnants. It’s a delicate finishing touch that clarifies the oil and dramatically extends its shelf life without stripping it of its character.

The Great Filtration Debate

With the oil polished, you face one of the most debated questions in the artisan olive oil world: to filter, or not to filter? There is no single right answer; it all depends on the experience you want to create.

-

Unfiltered Oil (Olio Nuovo): This is olive oil in its most raw, primal state. It’s cloudy, intensely flavorful, and often has a more aggressive, peppery kick. Tasting fresh olio nuovo is an unforgettable experience, but it’s a fleeting one. The same fruit particles that give it that robust character will also cause it to spoil much faster. Think of it as a seasonal treat, meant to be consumed within a few short months.

-

Filtered Oil: The vast majority of high-quality extra virgin olive oil is filtered. The process involves passing the oil through inert materials like cotton to remove the final suspended solids. This doesn't harm the oil—it protects it. By removing the sediment, filtration ensures the oil remains stable, preserving its fresh flavors for 18-24 months. It's the standard for any producer who wants their oil to be enjoyed year-round.

Think of it this way: Unfiltered oil is a brilliant firework—dazzling for a moment but gone in a flash. Filtered oil is a perfectly cut diamond—stable, brilliant, and built to last.

The Three Enemies of Olive Oil

Once your oil is clean and clear, the final battle begins. Three relentless enemies are constantly working to degrade its quality. Protecting your oil means fighting a constant war against them.

- Oxygen: Air is public enemy number one. Oxygen drives rancidity, breaking down the oil's healthy fats and creating stale, waxy, crayon-like off-flavors.

- Light: UV light acts as a catalyst, dramatically accelerating the oxidation process. An oil stored in a clear bottle on a sunny windowsill can turn rancid in a matter of weeks.

- Heat: Warmth is an accelerator for every negative chemical reaction in olive oil. Storing your oil next to the stove is a surefire way to destroy its delicate aromas.

This defense is more critical than ever. Global olive oil production hovers around 3 million tons annually, but climate stresses are hammering yields in the European Union, which accounts for over 60% of that total. You can see more about the trends impacting olive oil production on usetorg.com. This makes every well-preserved drop even more precious.

The gold standard for bulk storage is stainless-steel tanks, often called fusti. To take protection to the next level, producers top these tanks with an inert gas like argon or nitrogen. This creates a protective blanket over the oil, preventing any contact with oxygen.

For anyone wanting to dive deeper, our guide to proper olive oil storage has essential tips for both producers and consumers. By controlling these final variables, you ensure the magnificent flavor you worked so hard to create in the mill is the same one your customer gets to experience when they finally open the bottle.

Your Top Olive Oil Questions, Answered

Even with the best guide, making olive oil for the first time brings up a ton of questions. Let's tackle some of the most common things people ask, whether they're just curious foodies or thinking about pressing their own small batch.

How Many Olives Does It Take to Make a Liter of Oil?

This is the classic question, and the answer is always, "It depends." The yield can swing dramatically based on the olive variety, ripeness at harvest, and the efficiency of the mill.

That said, a good rule of thumb is that you'll need around 5 to 6 kilograms (or 11 to 13 pounds) of olives to produce one liter of high-quality extra virgin olive oil.

But this is just an average. If you're chasing those intensely green, peppery flavors from an early harvest, be prepared for a much lower yield. Those young, unripe olives are packed with polyphenols but less oil, so it's not unusual to need 10 to 12 kilograms for a single liter. On the flip side, late-harvest olives will give you far more oil, but you'll sacrifice that vibrant flavor and shorten the oil's shelf life.

Can I Make Real Olive Oil at Home?

The romantic image of pressing your own olives in the kitchen is appealing, but honestly, making true, high-quality olive oil without professional equipment is next to impossible. The process depends on specialized machinery that can crush the entire olive (pit and all) and then cleanly separate the oil from the vegetable water and solids—all without heat or oxygen getting in the way.

Trying to do this with a home blender or a fruit press usually results in a cloudy, low-grade liquid that will go bad very quickly.

If you have a few trees in your backyard, your best bet is to find a local custom mill (often called a frantoio) that will process small batches for a fee. This way, you get the satisfaction of using your own fruit while taking advantage of the equipment and expertise needed to produce a beautiful, stable oil.

What Actually Makes an Olive Oil "Extra Virgin"?

"Extra virgin" isn't just a marketing slogan—it’s a legal grade with ironclad chemical and sensory requirements. For an oil to earn this top-tier classification, it must pass two major tests.

First is the lab analysis. The most famous chemical marker is the free fatty acid (FFA) level, which must be below 0.8%. A low FFA is a strong indicator that the olives were healthy and processed quickly.

But that's only half the story. The oil must also be tasted by a certified sensory panel and be found to have zero defects. These aren't subjective opinions; they are specific, internationally recognized flaws like "musty," "fusty," or "rancid." An oil can have perfect chemistry, but if the panel detects even a single flaw, it gets downgraded and cannot be called extra virgin.

The "extra virgin" stamp is a promise of purity. It certifies that the oil is simply the fresh juice of the olive, extracted using only mechanical methods, with no heat or chemicals involved.

Achieving this grade is a testament to the entire process, from a well-tended grove to a spotless mill. Any misstep along the way will reveal itself in the final product, which is why learning how to tell if olive oil is rancid is such a valuable skill for anyone who loves good food.

At Learn Olive Oil, we believe that knowing the story behind the bottle is the key to truly appreciating it. Our mission is to give you the knowledge to choose, taste, and cook with the world's best olive oils like a pro.

Explore our guides and start your journey to becoming an olive oil connoisseur today at https://learnoliveoil.com.

Leave a comment