To truly understand how they make olive oil, you must first walk through the groves. The soul of the oil is born long before the press, right there on the branch. It is the ripeness of each sun-drenched olive that dictates the oil’s final character, shaping its destiny to become either a fiery, peppery elixir or a whisper-soft, buttery treasure.

The Journey From Olive Grove to Harvest

The story of any exceptional olive oil is written in the field, not in the factory. It all begins with the harvest—a breathless race against time where every decision is a brushstroke on the final masterpiece.

Producers must pinpoint that one fleeting moment to pick. Harvest too soon, and you capture an intensely green, spicy oil with a fiery spirit. Wait a moment too long, and the oil mellows into something far more buttery, sacrificing its vibrant, youthful vigor.

Finding this razor’s edge of perfection is why timing is everything. It is a secret whispered down through generations, a sacred blend of science and an almost primal connection to the grove's rhythm. Of course, before any olives can be harvested, they must be grown. For anyone curious about that first monumental step, there are brilliant guides on cultivating an olive tree.

Harvesting Methods: The Old and The New

Once the moment arrives, the methods for coaxing the olives from the trees vary dramatically.

Traditional growers often cling to hand-raking, a gentle art that keeps bruising to a whisper. In stark contrast, many modern operations unleash mechanical shakers that vibrate the tree, sending a shower of olives onto nets spread below. Each method presents a classic trade-off: the artisan’s delicate touch versus the machine's relentless efficiency. Our detailed guide on olive oil harvesting explores these fascinating techniques in greater detail.

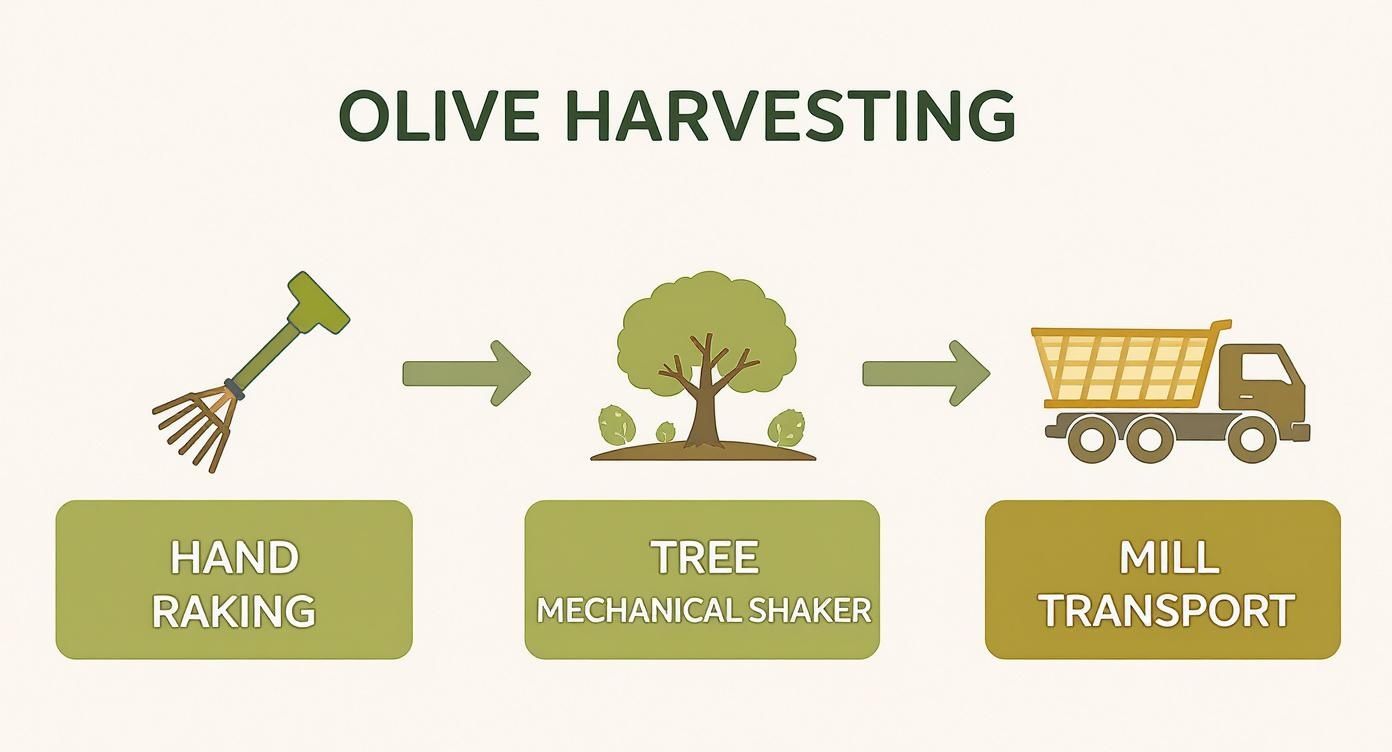

The infographic below offers a bird's-eye view of the journey from tree to mill.

The choice of harvesting method directly sculpts the oil's final profile. A gentle hand-pick preserves the olive's integrity, leading to a pristine, flawless taste. Mechanical methods, though astonishingly fast, risk introducing minor defects if not wielded with an expert hand.

Here is a quick comparison of these philosophies.

Harvesting Methods and Their Impact on Olive Oil Quality

| Harvesting Method | Key Benefit | Potential Drawback | Best For |

|---|---|---|---|

| Hand-Picking/Raking | Minimal bruising, preserves fruit integrity | Labor-intensive and slow | Artisanal, small-batch, premium EVOOs |

| Mechanical Shakers | Extremely fast and efficient | Can bruise fruit if not operated carefully | Large-scale production, efficiency-focused farms |

| Pneumatic Rakes | Faster than hand-raking, gentler than shakers | Requires skilled operators, potential for some damage | Medium-sized groves seeking a balance of speed and quality |

Ultimately, no matter the method, the goal is singular and absolute: get perfect, unblemished fruit to the mill with the urgency of a rescue mission.

From Branch to Mill: A Critical Race

This frantic sprint from grove to mill is non-negotiable for anyone aspiring to create liquid gold. The entire rhythm of olive oil production is chained to these agricultural cycles.

Even the heavens play their part. A season of heavy spring rains might promise a bountiful crop, but a sudden summer heatwave can dash those hopes in an instant. It is a fragile dance between nature and producer. The 2023 harvest, for example, saw production in some regions plummet by over 50% due to punishing drought, a stark reminder of nature’s ultimate power.

The clock starts ticking the second an olive leaves its branch. Every minute delayed is a small chip away from the final quality, allowing unwanted flavors to develop.

This first stage—the harvest—is where excellence is born. It is the bedrock upon which an oil will be judged as merely good, or truly, breathtakingly, extraordinary.

Inside the Mill: The First Crush

Once the freshly harvested olives storm the gates of the mill, the race against time is won. Now, the alchemy begins. Banish the romantic image of giant stone wheels grinding away; today’s temple of olive oil is a gleaming sanctuary of stainless steel and precise temperature control. All the potential so carefully nurtured in the grove can be either fully realized or squandered in these next few crucial hours.

The first order of business is transforming whole olives into a thick, fragrant paste. This is more than mere crushing; the goal is to rupture the fruit's very cells to liberate the microscopic droplets of oil trapped within. Modern mills achieve this with stunning speed using a hammer mill, a powerful machine that pulverizes olives into the perfect consistency in mere seconds.

The Secret of the Cold Press

You have undoubtedly seen "cold-pressed" emblazoned on a label, but what does it truly mean? It is a sacred vow to maintain a low temperature—ideally below 27°C (80.6°F)—from the moment the olives are crushed until the oil is separated. This isn't a friendly suggestion; it is the unbreakable law of extra virgin olive oil.

Heat is the sworn enemy of quality. Applying heat would certainly extract more oil, boosting profits. But the cost is catastrophic. It would utterly obliterate the delicate aromas, the fresh flavors, and the health-giving antioxidants like polyphenols that are the very soul of a premium oil. Any true artisan knows that sacrificing a little quantity is a small price to pay for preserving the oil's vibrant, peppery life force. To truly grasp the significance of this, our guide on first-press olive oil reveals why this principle is so sacred.

Malaxing: The Slow Churn to Perfection

After the olives become paste, the journey continues to a critical stage known as malaxing. The olive paste is gently swept into large, horizontal troughs where spiral blades turn, slowly and continuously, for the next 20 to 45 minutes.

This slow, methodical mixing is not for show. It serves a vital purpose: encouraging the millions of tiny oil droplets released during crushing to find one another and coalesce into larger drops. This makes the oil infinitely easier to separate from the solids and water later on. It is during this patient churn that the oil's complex aromatic profile truly awakens, releasing its signature symphony of fresh-cut grass, fruit, and spice.

This is where the path splits. An industrial producer might rush this step to push more volume through the mill. A dedicated artisan, however, gives the paste all the time it needs to develop its full, nuanced spectrum of flavor.

The sheer scale of modern production is staggering. Over the last century, the industry has leaped from manual, back-breaking methods to hyper-mechanized operations. Today, a large mill in Spain can process over 1,000 tons of olives every single day during peak season, relying on continuous centrifuge systems that handle hundreds of kilos per hour. This remarkable efficiency ensures the journey from fruit to paste is breathtakingly swift, protecting the oil from oxidation before the next step begins.

Extracting Liquid Gold From the Olive Paste

After the patient, deliberate work of malaxing, the olive paste is ready. It is a fragrant, glistening slurry, and those tiny oil droplets have merged, poised for liberation. Now comes the moment of truth: extracting that liquid gold from the fruit solids.

This is where the oil is finally separated from the leftover solids (called pomace) and vegetable water. The method a producer chooses speaks volumes about their priorities. Is their goal to squeeze out every last drop for maximum yield? Or is it to protect the delicate flavors and precious antioxidants at all costs? The two main approaches could not be more different.

The Charm of the Traditional Press

For centuries, making olive oil meant one thing: a press. You’ve seen the images. The olive paste is smeared onto round, woven fiber mats, which are then stacked high and squeezed under immense hydraulic pressure.

This pressure literally forces the liquids—a mix of oil and water—out of the paste, which then dribbles into a collection tank. It's a romantic, old-world image, but it comes with dangerous flaws. Those fiber mats are a nightmare to clean and can easily harbor old, musty flavors that will contaminate the new oil. Worse, the entire process exposes the oil to oxygen for an extended period, the mortal enemy of the precious polyphenols that give high-quality oil its peppery bite and health benefits.

While beautiful to watch, the traditional press is a slow, less controlled method that promotes oxidation. That's why you'll rarely see it used by producers who are serious about making top-tier extra virgin olive oil.

The Precision of the Modern Centrifuge

This is where modern technology triumphs. The hero of today's high-quality olive mill is the decanter centrifuge. Picture a massive, horizontal stainless steel cylinder spinning the olive paste at incredible speeds—often over 3,000 rotations per minute.

This powerful spinning action creates immense centrifugal force, separating everything inside based on its density. The heaviest components, the solids, are flung to the outer wall. The lightest, the pure oil, gathers in the center. The vegetable water settles in a layer between them. It is all accomplished in a sealed, continuous system that separates the oil with astonishing speed and precision.

The benefits are undeniable:

- Speed: The process is incredibly fast, drastically reducing the oil's exposure to air.

- Hygiene: Gleaming stainless steel is easy to sanitize, eliminating the risk of contamination or off-flavors.

- Control: Modern centrifuges grant the miller absolute control, helping to preserve the oil's fragile chemistry.

This swift, clean separation is absolutely essential for locking in the oil’s quality from the very start. The choice of extraction method is paramount, and for a more detailed comparison, you can explore the various techniques for extracting olive oil in our deeper dive. By embracing centrifuge technology, millers can capture those fresh, vibrant flavors right after the crush, ensuring the oil in the bottle is as pure and delicious as nature intended.

Guarding the Gold: Clarifying and Storing the Final Product

Extracting the oil from the paste feels like victory, but the battle for quality is far from over. This is the stage where many potentially great oils begin their tragic decline. The beautiful, green-gold liquid flowing from the decanter is not yet the finished product. It is still cloudy, filled with microscopic bits of olive and tiny water droplets.

Leaving those particles in the oil is an invitation to disaster. They eventually sink, forming a layer of sediment that begins to ferment. This process is a flavor-killer, introducing foul notes and dramatically shortening the oil’s shelf life. The true art isn't just making the oil; it's preserving its perfection.

The Final Polish

To achieve a stable, brilliantly clear oil with a long life, producers perform one last separation. This is the job of a vertical centrifuge. Think of it as a high-speed polishing machine. The oil is fed into this device, which spins at an even more incredible speed than the decanter, using pure force to strip out the last remaining impurities.

The heavier water and solids are flung to the sides and siphoned off, leaving behind nothing but pure, clarified olive oil. You might hear some producers praise olio non filtrato (unfiltered oil) for its rustic charm. And while it can be sublime right after milling, its clock is ticking loudly. Those suspended solids will spoil it quickly. For any oil meant to last, this clarifying step is non-negotiable.

Olive Oil's Three Greatest Foes

Once the oil is pristine, it must be shielded from its three mortal enemies: oxygen, light, and heat. Any of these will trigger oxidation, the chemical reaction that turns a beautiful oil rancid and obliterates its healthy compounds. This is why proper storage is as vital as the milling process itself.

Top-tier producers immediately transfer their fresh oil into large, airtight stainless steel tanks. These are not mere holding vats; they are high-tech preservation chambers.

The entire goal is to put the oil into a state of suspended animation. You want to shield it completely from the outside world to lock in the exact flavor and aroma that was achieved on milling day.

These tanks are often topped with a blanket of inert gas, like nitrogen, which displaces any oxygen. The storage cellars are also kept at a constant, cool temperature, typically between 14-16°C (57-61°F), year-round. This dark, cold, oxygen-free environment is the ultimate defense, ensuring the oil tastes just as fresh months later as it did the moment it was born.

Want to keep your oil fresh at home? Our guide on proper olive oil storage has all the secrets you need.

The Final Steps: Bottling and Tasting

After the relentless work of harvesting and milling, the olive oil is nearly ready. It has rested in protective storage tanks, but now it faces the last leg of its journey: bottling. This isn't just about filling a container; it's the final, critical act of preservation and the first time its true character is officially judged.

The choice of packaging is paramount. You will almost never see a world-class olive oil in a clear glass bottle, and for good reason. Light is one of olive oil's worst enemies, rapidly degrading its delicate flavors and health benefits. This is why dedicated producers always choose dark green or brown glass, or even better, opaque tins. Think of the bottle as the oil's final fortress, shielding the liquid gold from harmful UV rays until the moment it reaches your kitchen.

Passing the Ultimate Test

Before any oil can be bottled, it must earn its title—specifically, the coveted ‘extra virgin’ designation. This is not some fanciful marketing term; it is a legally defined standard of quality, proven by both hard science and expert human senses.

An oil must clear two major hurdles to make the grade:

- Chemical Analysis: A sample is sent to a laboratory for the hard numbers. Technicians measure key markers like free fatty acidity and peroxide values, which provide a scientific snapshot of the oil's freshness and confirm it was made from healthy, undamaged olives.

- Sensory Evaluation: This is where art meets science. A certified tasting panel assesses the oil for its positive qualities and, more importantly, for any potential defects. No chemical test can ever replace the human palate in capturing an oil's complex soul.

During these final bottling stages, the design and information presented on custom food labels become vital. They not only build a brand but also convey the quality and story of the oil inside, building trust with the customer.

The Art of Professional Tasting

Watching an expert taste olive oil is a ritual of pure focus. They pour a little oil into a special blue-tinted glass—the color is intentional, masking the oil's hue to prevent any visual bias—and warm it in their hands to gently release its aromatic compounds.

The goal here is to pinpoint three key positive attributes: fruitiness (think notes of green apple, tomato leaf, or fresh-cut grass), bitterness on the tongue, and pungency (that signature peppery kick you feel in the back of your throat). A world-class extra virgin olive oil has a beautiful, harmonious balance of all three.

Next, they take a small sip and slurp it, a technique that aerates the oil across their entire palate. This allows them to detect any of the 16 official defects, like musty, fusty, or rancid notes. If a taster detects even a single defect, the oil automatically fails the test. It simply cannot be called extra virgin.

This final, meticulous assessment ensures that the bottle you pick up is truly the best it can be. If you're curious to train your own palate, you can dive deeper and learn how to taste olive oil like the pros do.

Common Questions About Making Olive Oil

https://www.youtube.com/embed/jyYNaQ92zEM

Even after walking through the entire process, from the olive grove to the final bottle, a few questions always seem to come up. The olive oil world is packed with tradition and specific lingo, so it's only natural to be curious. Let's tackle some of the most common points of confusion.

What Does "Cold-Pressed" Really Mean?

One of the biggest questions I get is about the term "cold-pressed." Here’s the secret: true "pressing" is quite rare these days, at least for high-quality production. Most modern mills use a centrifuge, not a press.

So, the term has evolved. Today, it really means "cold-extracted." It’s a promise that the entire process—from crushing the olives into a paste to spinning the oil out in the centrifuge—was kept below a strict temperature threshold of 27°C (80.6°F). Why is this so important? Keeping the temperature low is crucial for preserving the oil’s delicate flavors, aromas, and all those healthy polyphenols.

Is Greener Olive Oil Better?

Another common question is about color. Is that deep, vibrant green oil automatically superior to a golden one? Absolutely not.

An oil's color simply tells you about the ripeness of the olives and how much chlorophyll remains. A bright green hue usually signals an early harvest oil, which often comes with a bold, peppery kick. A more golden oil, on the other hand, can be just as delicious and complex, often with buttery or nutty notes.

Fun fact: Professional tasters use special blue-tinted glasses so they can't see the oil's color. This forces them to judge it purely on aroma and taste, removing any visual bias. It’s a great reminder that color isn't a true indicator of quality.

What Is the Difference Between First Press and Extra Virgin?

This is another one of those terms that’s a relic from older, traditional methods. Back in the day, mills would press the olive paste multiple times. "First press" referred to the very first, highest-quality oil that came out. Any subsequent presses produced a lower-grade oil.

But with modern centrifuges, there is only one extraction. The idea of a "second press" is obsolete.

So, here’s the bottom line: all true extra virgin olive oil is, by its very nature, a "first press" product.

- First Press: Think of this as an outdated marketing term that’s now basically synonymous with extra virgin.

- Extra Virgin Olive Oil (EVOO): This is the official, legally regulated top grade. To earn this label, the oil must have zero flavor defects and pass a battery of chemical tests.

When you see "first cold-pressed" on a label, it's really just a slightly redundant way of saying "extra virgin." It's a nod to tradition, confirming the oil came from the one and only extraction process and was made without excessive heat. The most important thing to look for is always the EVOO designation.

At Learn Olive Oil, we're dedicated to helping you explore the rich world of high-quality olive oil. From understanding labels to mastering tasting techniques, we provide the expert insights you need. Discover the World of Premium Olive Oil.

Leave a comment