Picture this: liquid gold seeping from crushed, sun-ripened olives. At its heart, extracting olive oil is a straightforward mechanical dance—crush the fruit into a paste, then press out the oil. Yet achieving true extra virgin olive oil—with its vibrant flavor and health-boosting power—demands a master’s touch. It’s not just extraction; it’s the art of capturing peak taste and nutrition in every drop.

The Art of Capturing Liquid Gold

Before any machine whirs to life, the grove holds the secret. The press is merely the instrument; the soul of an extraordinary olive oil is born in the orchard, guided by intuition, timing, and reverence for the olive.

One day too early or one day too late in harvesting can spell the difference between a flat, unremarkable oil and one bursting with peppery life. Your choices among the trees define whether you produce a run-of-the-mill cooking oil or a complex, aromatic masterpiece.

The Moment of Perfect Ripeness

Timing isn’t just important—it’s everything.

Underripe olives deliver a grassy, biting oil; overripe ones yield a soft, insipid liquid that won’t endure. That fleeting window of ideal ripeness? It’s your golden ticket.

How do you seize it? You learn to read the fruit:

- Watch the Color Shift: Seek the inveria stage—when skin morphs from bright green to a mix of purplish-black. A mosaic of hues often heralds deeper complexity.

- Feel the Give: Gently squeeze. The right olive feels firm yet yielding—never rock-hard, never mushy.

- Do the Juice Test: Crush one between your fingers. Creamy, milky juice means go-time; clear, watery liquid means wait a little longer.

You must master the 'why' before the 'how.' Every step—milling, pressing, separating—depends on the caliber of olives you bring in. For insight on how region shapes ripening, explore the diverse origins of olive oil.

Turning Fresh Olives Into a Rich Paste

With olives harvested at their peak, it’s time to transform them into a fragrant, oil-rich paste. Precision here begets perfection later.

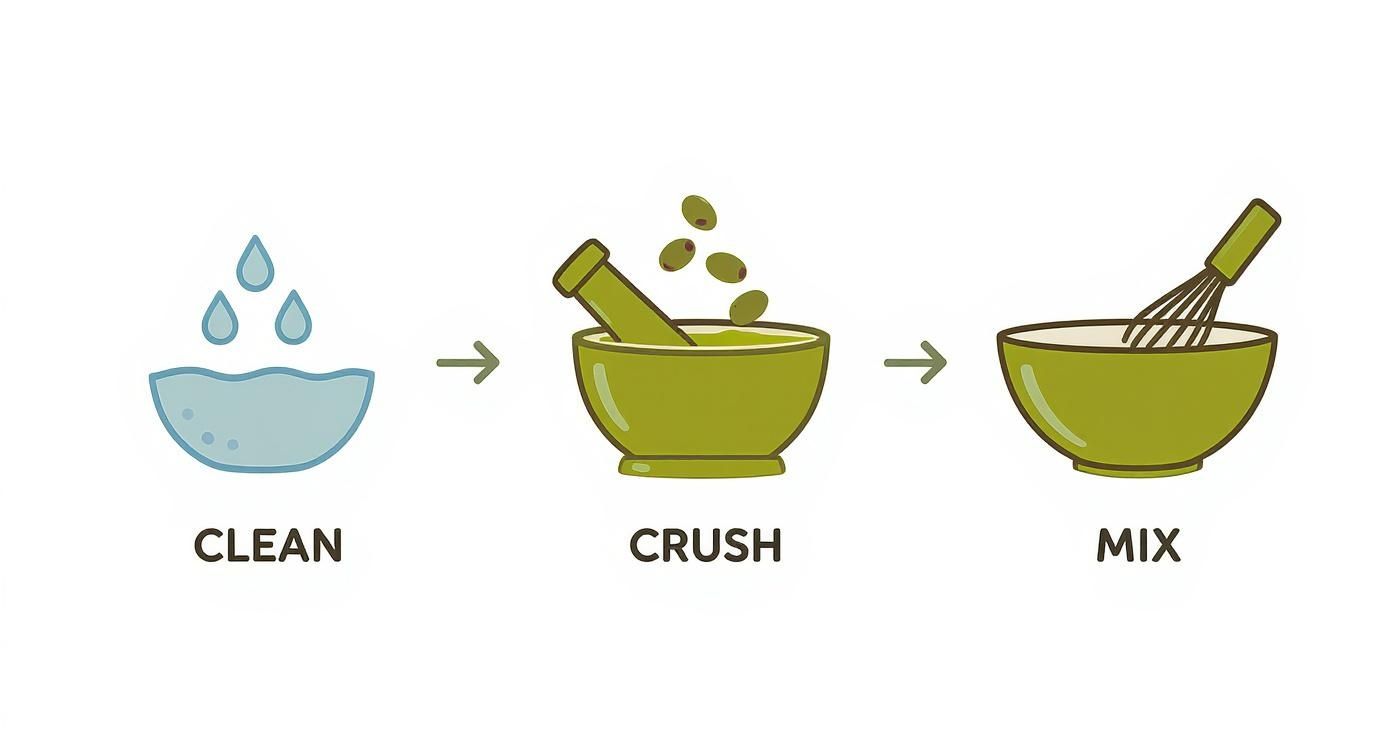

First, purge every leaf, twig, and speck of dirt. A single leaf can taint your batch with unwanted bitterness. This isn’t casual cleaning—it’s the foundation of purity.

The First Step: The Crush

Now, break down the fruit—pit and all—into a coarse paste. Old-world mills used granite wheels; today’s hammer mills do the job. The aim isn’t pulverization but a gentle rupture of cell walls (the mesocarp), where precious droplets of oil lie hidden.

Heat is your adversary; crush just enough to coax the oil free without firing up unwanted warmth.

The Magic of Malaxation

Your mash now needs mixing—slowly and deliberately. Malaxation is the soul-stirring phase where oil droplets unite into larger beads, ready for extraction.

For 20–40 minutes, keep the paste between 20–27°C (68–81°F). Too cold, and the oil won’t coalesce; too hot, and you’ll scorch away the phenols and antioxidants that give true extra virgin its character and bite.

Malaxation crafts the oil’s aroma and zip. Adjust times for different varieties—longer for a robust Coratina, shorter and chillier for a delicate Arbequina.

As the paste glimmers and smooths, you know you’re on track. For deeper context on these early stages, see our guide on the complete olive oil harvesting and preparation process.

Pressing for Purity: The Heart of the Process

This is the crescendo. All your grove-side decisions and atelier craft converge in the press—where fragrant mash becomes liquid gold.

Whether you opt for a traditional cold press or a modern centrifugal decanter, the rule is the same: gentle, steady pressure, with zero tolerance for heat.

Think of your tools as revealing agents—they don’t make the oil, they merely uncover its glory.

The Cold Press Commitment

"Cold-pressed" is more than a buzzword; it’s a vow. The paste must never exceed 27°C (81°F). This restraint traps polyphenols and antioxidants in a time capsule of freshness. Learn why in what makes cold-pressed olive oil superior.

Modern Methods: The Centrifugal Decanter

Many producers favor the decanter’s high-speed elegance, where density does the sorting:

- Pomace: Heaviest, flung outward.

- Water: Middle layer.

- Oil: Lightest, collected at the core.

Decanters extract more oil, faster—but temperature control remains the golden rule, enforced by built-in cooling.

Olive Pressing Methods At a Glance

| Feature | Traditional Cold Press | Centrifugal Decanter |

|---|---|---|

| Process | Hydraulic squeeze of mats layered with paste. | High-speed spin separates by density. |

| Speed | Slower, batch-style. | Fast, continuous-flow. |

| Yield | Lower. | Higher efficiency. |

| Oil Quality | Exceptional; risk of oxidation on mats. | Excellent; retains freshness with cooling. |

| Temperature | Ambient, gradual pressure. | Requires integrated chill control. |

The machine reveals; you decide. Your vigilant tweaks ensure every last drop of high-grade oil is safely extracted and preserved.

Global production is pegged at 3.39 million metric tons for 2024/25, but beyond numbers, it’s detail and patience that define your batch’s brilliance.

How to Properly Store Your Liquid Treasure

Your oil is pressed—now begins the final act. Bottle too soon, and sediment and water will ferment, spoiling your masterpiece. Let gravity do its work through racking.

The Gentle Art of Racking and Decanting

Let unfiltered oil rest undisturbed for three to six weeks. Sediment settles; clear oil rises. Decant or siphon the top layer into a fresh vessel. Repeat until your oil shines like polished amber.

Racking isn’t about aesthetics—it’s about stability. Removing water and particles extends shelf life and locks in purity.

Shielding Your Oil from Its Mortal Enemies

Three arch-nemeses lurk:

- Oxygen: Airtight seals and brim-to-brim filling thwart oxidation.

- Light: UV rays ravage polyphenols—never store in clear glass.

- Heat: Keep oil cool; avoid stoves and windowsills.

Dive deeper with our guide on effective olive oil storage techniques.

Choosing the Perfect Vessel

Pros prize stainless steel fusti—light-proof, inert, airtight. Home producers excel with dark green or amber glass. Beware generic plastics; they can bleed off unwanted compounds. For large caches, consider reconditioned IBC totes with UV light protection and food-grade history.

Find a cool (14–18°C/57–65°F), dark, and steady spot—cellars or pantries work wonders. This final, careful step seals in the vibrant flavor you’ve crafted.

Working Through Common Pressing Problems

Even a flawless plan can hit bumps. The mark of a true artisan is not avoiding missteps but reading their signals and correcting course.

What to Do About Unwanted Flavors

Your palate is your most honest critic:

- Muddy/Earthy: Too many leaves or twigs snuck in, infusing unwanted chlorophyll.

- Greasy/Flat: Over-mixed or overheated paste oxidized prematurely.

- Aggressive Bitterness: Underripe fruit—wait an extra day or two.

Other defects:

- Winey/Vinegary: Fermentation from delayed pressing.

- Metallic: Contact with non-food-grade metals.

- Rancid: Oxidation—check paste temp and storage conditions.

When You Get a Disappointingly Low Yield

Yield woes usually trace back to process, not machinery. Ask:

- Was malaxation too brief or too cold?

- Did your olives naturally have low oil content? Varietals like Picual can yield up to 25%; others far less.

Supply crunches loom—2025/26 production may dip to 3.016 million metric tons (USDA's global olive oil production forecast). Maximizing every drop is non-negotiable.

Gentle, methodical pressing—never a rogue hydraulic thrust—ensures more oil flows into your tank, not stuck in the pomace.

A Few Common Questions About Making Olive Oil

When you’re shoulder-deep in mash, these questions surface repeatedly. Let’s tackle them head-on.

How Many Olives Do I Actually Need for One Liter of Oil?

There's no magic formula, but expect 5–10 kilograms of olives per liter of oil. Variations depend on:

- Variety: Picual vs. low-yield types.

- Ripeness: Earlier picks yield less.

- Extraction Efficiency: Press vs. decanter matters.

Forget chasing a number; master each step, and your olives will give up their best.

Can I Use the Olives From My Backyard Tree?

Yes—and it’s unbelievably rewarding. But ornamental varieties may offer low yields or unusual flavors. Test first:

- Harvest 2–3 kg.

- Run a small press or even a kitchen juicer.

- Taste and measure your result before a full-scale effort.

What Does "Extra Virgin" Really Mean, and Can I Make It?

"Extra Virgin" is a certified standard: mechanical extraction only, free acidity under 0.8%, and no flavor defects. By following our cold-press protocol, you’re already on the path to true extra virgin quality.

For DIY testing, see how to test olive oil at home and learn to validate your oil’s purity and flavor.

At Learn Olive Oil, our mission is to demystify the art and science of olive oil, helping you create something wonderful right in your own kitchen. We're here with expert advice to make the journey from grove to table a rewarding one. https://learnoliveoil.com

Leave a comment