The creation of olive oil is a true agricultural art, a craft that turns a simple fruit into what many call "liquid gold." This journey is all about patience and precision. It starts in groves bathed in sunlight and finishes in a bottle on your shelf, with every single step along the way—from the moment the olive is picked to the second it's pressed—defining the oil's unique character, its rich flavor, and its overall quality.

From Sun-Kissed Grove to Liquid Gold

Picture a place where time slows down, under the warmth of the Mediterranean sun. This is where the story of olive oil really begins. It’s not in a sterile factory but in ancient groves, some of which have been tended by the same families for generations. The transformation of a bitter, raw olive into a bottle of fragrant, complex oil is a beautiful testament to tradition and painstaking care.

The process is much more like winemaking than it is like standard food manufacturing. The very soul of the land—what the French call terroir—is captured in every drop. The soil, the climate, the slope of the hills… it all matters. Every decision made by the grower and the miller has a profound effect on what you ultimately taste.

The Artistry Behind The Bottle

Making incredible olive oil isn't just a series of mechanical steps; it’s a delicate dance between art and science. From determining the perfect day to harvest to choosing the exact temperature for the press, every choice is critical. This guide will pull back the curtain on this timeless tradition and show you the true artistry behind one of the world's most essential foods.

We’ll walk through:

- The Critical Harvest: We'll explore why the timing of the harvest is arguably the single most important decision a producer makes.

- The Mill's Magic: You'll see how modern technology and ancient wisdom work together to gently coax the oil from the fruit.

- Guarding the Gold: We'll cover the final, crucial steps of filtering and storing that protect the oil’s delicate flavors and purity.

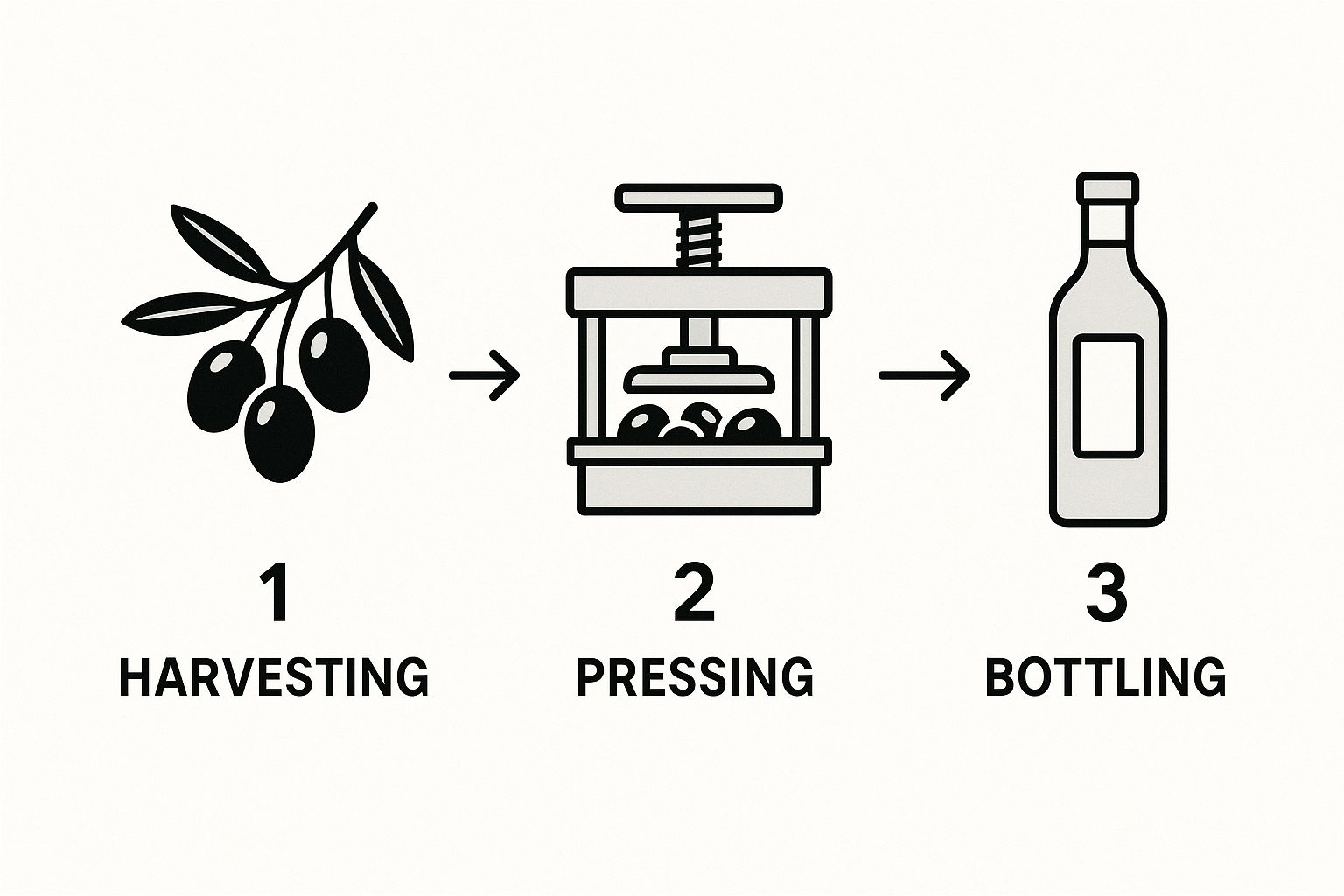

Let's start with a high-level look at the key stages that take an olive from the tree to the bottle.

The Olive's Transformation Journey

Here's a quick overview of the key stages in making olive oil, from the grove to your bottle.

| Stage | Core Objective | Impact on Final Quality |

|---|---|---|

| Harvesting | Pick olives at the peak of ripeness without bruising the fruit. | Timing determines the flavor profile (grassy vs. buttery) and polyphenol content. Bruising causes defects. |

| Milling | Crush the olives into a paste and extract the oil as quickly as possible. | Speed is essential. The longer the wait, the higher the risk of oxidation and off-flavors. |

| Malaxation | Gently mix the olive paste to allow small oil droplets to combine. | This step develops the oil's aroma and flavor. Temperature control is critical to preserve delicate compounds. |

| Extraction | Separate the oil from the solid pomace and vegetable water. | Modern centrifuges do this efficiently without heat, preserving the oil's "extra virgin" status. |

| Storage | Protect the finished oil from its enemies: oxygen, light, and heat. | Proper storage in stainless steel vats under nitrogen ensures the oil stays fresh and vibrant until bottling. |

Each step is a link in a chain, and the final quality is only as strong as the weakest link.

As you can see, the process looks straightforward on the surface. But true mastery is what separates an average, forgettable oil from an exceptional one that sings with flavor.

The greatest olive oils are not merely produced; they are guided. The producer's role is to shepherd the olive's natural essence from the tree to the bottle with as little intervention as possible, preserving the voice of the grove itself.

At the end of the day, the quality of any olive oil comes down to preserving the integrity of the fruit. This absolute dedication to purity is what defines the entire process from start to finish. To get a better handle on the different grades you see on store shelves, it helps to learn more about what is pure olive oil and how it stacks up against other varieties. Arming yourself with that knowledge is the key to truly appreciating the craft.

The Art and Science of the Olive Harvest

Timing is everything. After a year of sun, rain, and patient tending, an entire season’s work hinges on one brief, critical window of time. This is the moment the fruit reaches a perfect alchemy of flavor, aroma, and health-boosting antioxidants. Miss this window—even by a day—and the soul of the oil is lost forever.

This is the intense, high-stakes world of the olive harvest. It’s a frantic race against the clock. The “when” and “how” of picking are, without question, the most fateful decisions a producer will make all year. They draw the line between a truly legendary olive oil and one that's just… ordinary.

Hand Raking vs. Mechanical Shaking

Out in the groves, you'll see two vastly different approaches to getting the olives off the trees.

First, there's the gentle, time-honored tradition of hand-raking. Workers use small, comb-like rakes to carefully coax the olives from their branches, letting them fall onto nets spread out below. It’s a slow, back-breaking process, but it treats the fruit with the reverence it deserves, minimizing damage.

Then you have the sheer force of modern mechanical shakers. These machines grip the tree's trunk and vibrate it with startling intensity, causing a rain of olives to fall in just seconds. It’s fast. It’s economical. But that efficiency comes at a cost. The risk of bruising the delicate fruit is dramatically higher.

The moment an olive's skin breaks or it gets bruised, oxidation kicks in. This process is the arch-enemy of quality, creating off-flavors and driving up acidity. The clock literally starts ticking the second an olive is separated from its branch.

The Mad Dash to the Mill

You cannot overstate the urgency of this next step. The world's most celebrated extra virgin olive oils go from the branch to the press in an astonishingly short time—often in less than four hours.

This mad dash to the mill is the secret to capturing the olive's absolute peak of freshness, locking in the vibrant, peppery polyphenols that are the source of its health benefits. Any delay opens the door to oxidation and fermentation, the twin villains that will ruin a batch of high-quality oil.

This obsession with speed and careful handling is what truly separates the best from the rest in the making of olive oil. It's an expensive, demanding commitment, but you can taste the difference—and feel the health benefits—in every single drop. For a closer look at these techniques, check out our deep dive into olive oil harvesting methods and their impact on quality.

Of course, weather always has the final say, leading to huge swings in global production. The 2024/25 season is a perfect example: Spain's output is forecasted to leap by 52%, while a brutal drought in Italy is expected to cause a major drop. These regional shifts are a stark reminder of the delicate balance producers face every single year. You can read more about these global production forecasts on oleista.com.

Inside the Mill: The Alchemy of Extraction

Welcome to the almazara—the olive mill. Once the olives arrive, the clock is still ticking furiously. This is where the fleeting freshness of the harvest is either captured forever or lost for good. After a quick but thorough cleaning to wash away dust and remove leaves, the fruit goes straight into the crusher.

Modern mills use powerful steel hammer mills that shatter the olives, pit and all, in a matter of seconds. The result is a vibrant, fragrant, and brilliantly colored paste. The aroma is absolutely intoxicating: a blast of fresh-cut grass, green tomato, and pungent herbs. This paste holds all the potential of the final product, but the precious oil is still locked away in microscopic droplets.

The Gentle Art of Malaxation

What comes next is arguably the most delicate and least understood step in making world-class olive oil: malaxation. The olive paste is moved into a trough where large augers slowly and gently turn it over and over. This isn't about brute force; it's a patient, deliberate churning.

Think of it like coaxing millions of tiny balloons filled with oil to pop. The goal of malaxation is to gently break them open and encourage all those microscopic droplets to find each other and merge into larger, more easily extractable drops. It’s a slow dance that develops the oil's full aromatic complexity.

Temperature is the single most critical variable during malaxation. This is where the term "cold-pressed" gets its modern meaning. To preserve the delicate flavors and health-giving polyphenols, the paste must stay below 27°C (about 80.6°F). Go any warmer, and you might get a little more oil, but you sacrifice its very soul in the process.

The Final Separation

Ancient millers used heavy stone presses and woven mats to squeeze the oil out—a slow process that exposed the oil to a lot of damaging oxygen. Today, the world’s best oils are made using a far superior method: the decanter centrifuge. This gleaming stainless-steel machine is the heart of any modern mill.

The olive paste is pumped into the centrifuge, which spins at incredibly high speeds. This immense force separates everything inside by density:

- The Pomace: The heaviest solid parts (skin, pulp, pit fragments) are flung to the outside wall.

- Vegetable Water: The water from the olive fruit forms the next layer.

- The Olive Oil: As the lightest component, the pure, golden-green oil collects right in the center.

The entire separation is lightning-fast and happens in a sealed, oxygen-free environment. No heat or chemicals are ever involved. It cleanly spins the pure oil away from everything else, capturing the fruit's essence at its absolute peak. You can learn more about the specifics of modern olive oil extraction and see how technology is used to preserve ancient quality.

From here, the brand-new oil is ready for its final journey of clarification and rest.

Protecting the Purity of the Final Product

Once the centrifuge has worked its magic, the journey is far from over. What emerges is a cloudy, vibrant, and completely raw mix of oil, water, and tiny particles of olive. The next steps—clarification and storage—are the unsung heroes that protect the oil's quality, flavor, and lifespan. This is where a producer's commitment is truly tested.

They arrive at a fork in the road: decant or filter? Some artisan producers will bottle their oil completely unfiltered, embracing its cloudy look and bold, rustic taste. This is often called olio nuovo (new oil), a seasonal delight cherished for its intensity but with a much shorter shelf life. Why? Because those suspended fruit particles, while delicious at first, eventually settle and can cause the oil to go bad.

Preserving Freshness for the Long Haul

For this reason, most top-tier producers insist on filtration. They gently pass the fresh oil through thick cotton filters, a process that removes the last traces of water and sediment without stripping away any of the flavor or precious polyphenols. It's a critical step that ensures the oil is brilliantly clear, stable, and will hold onto its peak freshness for up to two years. It’s a promise of purity.

The greatest enemy of fresh olive oil isn't time; it's exposure. Oxygen, light, and heat are the three assassins that will degrade its flavor, destroy its health benefits, and turn liquid gold into a rancid disappointment.

To fight these threats, modern producers use massive stainless-steel tanks called depositos. Here, the oil rests in a cool, dark, and oxygen-free space, often shielded by a protective layer of inert nitrogen gas. This is a quiet but crucial resting period where the oil settles and its complex flavors meld together, creating the masterpiece you expect in the bottle.

This level of care is vital, especially as global producers work to meet incredible demand. Spain, for example, produces about 40% of the world's olive oil, a staggering figure that highlights the scale of modern production.

Ultimately, these protective measures are what separate the real artisans from those who cut corners. Understanding this dedication to quality is the first step when you learn how to spot fake olive oil on the supermarket shelf.

Decoding Olive Oil Quality Like an Expert

Not all olive oils are created equal. In fact, a vast ocean of difference separates a sublime Extra Virgin Olive Oil from a generic bottle labeled ‘pure’ olive oil. That difference comes down to chemistry, sensory experience, and a producer’s deep commitment to their craft. Learning to spot these differences gives you the power to become a truly discerning buyer, moving past the label to understand the liquid gold inside.

The official grades are your first clue. At the very top is Extra Virgin Olive Oil (EVOO), the highest grade possible. Think of it as pure, unadulterated fruit juice, extracted without chemicals or excessive heat. To earn this title, it must pass a battery of stringent chemical tests and a sensory analysis by a certified panel.

A step below that is Virgin Olive Oil. It’s also produced without chemicals but has some minor sensory defects and a slightly higher acidity level. Finally, you have Lampante Oil, an oil with such significant flaws that it's completely unfit for human consumption until it goes through an industrial refining process.

The Chemistry of Quality

One of the most revealing numbers in an oil's quality report is its free fatty acidity (FFA). Think of it as a damage report for the olives. When an olive is bruised, left to sit too long after picking, or is simply overripe, its cell walls break down. This unleashes enzymes that degrade the oil, causing its acidity to rise.

To qualify as Extra Virgin, an oil’s FFA must be below 0.8%. But for truly elite producers, that number is a ceiling, not a goal. The world’s best EVOOs often boast acidity levels below 0.3%, a powerful chemical signature of perfectly healthy fruit that was handled with extreme care.

A low FFA isn’t just a sign of quality; it also points to a longer, more stable shelf life. Understanding this simple number is a huge step toward decoding the story behind the label. Many producers take pride in their methods, so it's helpful to understand what is first cold-pressed olive oil and how it contributes to these low acidity levels.

Tasting Like a Professional

Beyond the lab tests, the true soul of an oil is revealed through taste and smell. When professionals taste olive oil, they aren't just looking for flaws; they are searching for three positive hallmarks that sing of freshness and quality.

- Fruitiness (Frutado): This is the aroma of fresh, healthy olives. It can range from delicate and floral to robust and grassy, with notes of green apple, artichoke, or tomato leaf.

- Bitterness (Amaro): A bitter taste on your tongue is not a defect! It’s actually a fantastic sign, indicating the oil was made from fresh, green olives and is a highly desirable trait.

- Pungency (Piccante): That peppery, cough-inducing sensation at the back of your throat is perhaps the most important sign of all. This is the direct sensory proof of oleocanthal, a powerful anti-inflammatory polyphenol found only in fresh, high-quality EVOO.

That peppery kick is the oil speaking to you. It's telling you that it’s fresh, healthy, and packed with life-giving antioxidants. Don't be shy—embrace it. It’s the taste of authenticity.

The Global Forces Shaping Your Olive Oil

The bottle of olive oil on your kitchen counter didn't just appear there. It is the final scene in a massive global drama, a story shaped by forces thousands of miles away—climate, economics, and agricultural cycles as old as the trees themselves.

When you understand these dynamics, you see why some years bring an abundance of incredible oil, while others leave us with shortages and sticker shock at the grocery store. A drought in the Mediterranean has a direct line to the price you pay. It’s a complex dance between nature and the market, where a heatwave in Spain sends ripples through kitchens all over the world.

The Rhythm of the Olive Tree

One of the most powerful natural forces in this story is something called alternate bearing. It's a fascinating phenomenon. Olive trees have a built-in rhythm: they'll produce a massive, high-yield crop one year, and then follow it up with a much smaller one the next. Think of it as the tree's way of catching its breath and conserving energy after an exhausting bumper crop.

This natural cycle is a huge driver of supply swings. A year of plenty is almost always followed by a leaner period, and every good producer has to plan for these predictable ebbs and flows.

The global olive oil market isn't a steady stream; it's a river that swells and shrinks with the seasons. Weather shocks, like unexpected freezes or prolonged droughts, can amplify these natural cycles, turning a lean year into a crisis or a good year into a record-breaker.

A World of Interconnected Fortunes

The global market is a delicate ecosystem where what happens in one country deeply affects another. Production from the titans of the industry, like Spain and Italy, can swing wildly from one harvest to the next, while smaller, emerging producers face their own unique hurdles. It all adds up to a volatile marketplace where supply forecasts are watched like a hawk.

For instance, the United States Department of Agriculture (USDA) is already forecasting a significant drop—roughly 10%—in worldwide production for the 2025/26 season. This includes an expected decline in the European Union (the world’s largest producer) and an even steeper drop in Turkey. Why? A big part of it is that alternate bearing cycle kicking in.

You can dive deeper into these global olive oil production forecasts on Olive Oil Times to see just how interconnected it all is.

Common Questions About Making Olive Oil

Diving into the world of olive oil can feel a bit overwhelming. Labels have specific terms, the process seems complex, and it’s natural to have questions. Let's clear up some of the most common things people wonder about how olive oil is made.

How Much Olive Oil Can You Get From One Tree?

This is a great question, but the answer really depends. A tree's output can swing wildly based on its age, health, the specific olive variety, and even the weather during the growing season. A good, mature tree can give you anywhere from 15 to 40 kilograms (that's about 33 to 88 pounds) of olives in a single harvest.

But here’s the kicker: it takes a lot of olives to get a little bit of oil. The general rule of thumb is you need about 5 to 6 kilograms of fruit to produce just 1 liter of extra virgin olive oil. So, when you do the math, one very productive tree might only yield about 3 to 8 liters of finished oil.

It's easy to assume that a huge pile of olives will result in a huge amount of oil. The truth is, it's a very low-yield process, which helps explain why authentic extra virgin olive oil is so prized. It truly reflects the incredible amount of fruit and hard work involved.

What Does "Cold-Pressed" Actually Mean?

Back in the day, "cold-pressed" literally meant the first pressing of olives using a traditional hydraulic press without any heat. Now, with modern equipment, the meaning has shifted slightly. The term now guarantees that the olive paste was kept below 27°C (80.6°F) during the entire mixing (malaxation) and extraction process.

Why does that temperature matter so much? Because heat is the enemy of quality. Keeping things cool is crucial for protecting the oil’s beautiful, delicate flavors, its fresh aroma, and all those healthy polyphenols. In fact, for an oil to even qualify as "extra virgin," it has to be produced this way. So while the term is a bit of a holdover, it’s still a great signpost for quality.

Why Does My Olive Oil Taste Bitter or Peppery?

If you taste a hint of bitterness or feel a peppery kick in the back of your throat, don't worry—that's a good thing! In fact, that's the signature of a fresh, high-quality extra virgin olive oil.

The bitterness comes from olives that were picked while still green and fresh, right at their peak. That peppery sensation? It’s caused by a powerful natural anti-inflammatory compound called oleocanthal. These are the clues your senses give you that the oil is packed with the antioxidants that make it so good for you.

At Learn Olive Oil, we're passionate about helping people understand the full story, from the olive grove all the way to the bottle. Knowing the journey is the best way to truly appreciate this liquid gold. We offer expert insights to help you choose, taste, and cook with confidence.

You can discover more at our website: https://learnoliveoil.com.

Leave a comment