Think about the difference between a sun-ripened tomato, plucked straight from the vine, and one that’s been sitting in a cold store for weeks. One is an explosion of flavor, a story of sunshine and soil. The other is a pale imitation. This is the difference at the heart of cold-pressed olive oil. It is more than a label on a bottle—it's a solemn promise to capture the true, unadulterated soul of the olive.

The Gold Standard of Purity

At its simplest, cold pressing is a method of coaxing the oil from the olive using only mechanical force, never heat. But why this obsession with temperature? Because heat is the sworn enemy of quality. You see, any producer can get more oil from the olives by heating them. But in doing so, they scorch the very life out of it—burning away the delicate flavors, the fragrant aromas, and the potent nutrients that make extra virgin olive oil one of nature's most perfect foods.

This careful, low-temperature craft is what separates the world’s finest oils from the mediocre masses. It is a philosophy that champions quality over quantity, every single time.

The Magic Number for Preservation

The entire art and science of this process can be distilled down to one critical rule: the olive paste must never exceed 27°C (80.6°F) during extraction. This isn't some arbitrary figure pulled from a hat. It is the scientifically proven threshold where the precious compounds within the oil begin to break down and vanish.

It’s like handling a delicate flower—a gentle touch preserves its pristine beauty, while a rough hand bruises it beyond recognition. By keeping the process cool, producers are acting as guardians of the oil’s integrity, ensuring its most valuable qualities survive the journey from the grove to your kitchen.

"Cold pressing is less an industrial process and more a form of preservation. It's about locking in the fleeting, precious essence of a freshly picked olive before it has a chance to escape."

This fanatical devotion to temperature control is what truly elevates an elite oil above the countless other bottles crowding the supermarket shelf.

What Does Cold Pressing Protect?

So, what exactly is being saved from the destructive power of heat? It's a roll call of everything that makes olive oil a titan in the kitchen and a champion for your health.

- Flavor and Aroma: The subtle, volatile compounds that gift an oil its grassy, fruity, or peppery personality are incredibly fragile. Heat makes them evaporate into thin air. Cold pressing keeps them locked in, vibrant and complex.

- Polyphenols: These are nature’s powerful antioxidants, like oleocanthal, responsible for that peppery kick in your throat and celebrated for their anti-inflammatory powers. Heat obliterates them.

- Vitamins and Nutrients: This gentle method also safeguards essential vitamins, most notably Vitamin E. You can learn more about the vital link between process and quality in our guide on what makes an oil first cold pressed.

To witness this commitment on a grand scale, look to the sun-drenched groves of Andalusia, Spain—the heartland of this ancient craft. As the world’s leading producer, Spain yielded a staggering 1,419,128 tons in a recent season. Over 70% of that liquid gold earns the coveted extra virgin grade, which demands cold-pressing to preserve its superior flavor and high polyphenol count. This unwavering dedication to staying cool is precisely why Spanish olive oil is celebrated across the globe.

From the Grove to the Bottle: How Cold-Pressed Oil is Made

Step into an almazara—the traditional Spanish name for an olive mill—and you enter a world where ancient craft shakes hands with modern science. This is where the alchemy happens. Where the humble, often bitter fruit is transformed into the liquid gold we cherish. It is a journey defined by meticulous care, astonishing precision, and a profound respect for the olive itself.

For centuries, the process conjured a romantic image: colossal granite millstones, turning slowly, patiently, crushing whole olives into a thick, fragrant paste. Speed was never the goal. The entire purpose was to gently rupture the fruit's cells, liberating the precious oil without generating destructive heat. It was a true labor of love.

Ancient Stones Meet Modern Steel

While the soul of cold pressing remains unchanged, the modern mill presents a different picture. Those weighty granite stones have largely given way to gleaming stainless steel hammer mills. These powerful machines perform the same essential task—crushing the olives—but with vastly superior control and hygiene.

This modern leap forward is a game-changer. It keeps oxidation and contamination at bay, ensuring the final product is as pure and fresh as nature intended. Yet even with this new technology, one sacred rule is honored above all others: the olive paste must remain cool throughout this entire first step.

Malaxation: The Art of the Gentle Stir

Once crushed, the olive paste enters a phase known as malaxation. Imagine it as a slow, meditative stirring session. The paste is moved into a horizontal trough where large paddles churn it for 20 to 40 minutes.

This is not idle mixing. This slow, deliberate motion coaxes the tiny droplets of oil released during crushing to find one another, merging into larger drops that are far easier to separate. It’s a delicate dance. Too little time, and you leave precious oil behind. Too much, and you invite oxidation, which creates foul, off-flavors. Temperature control here is absolutely paramount to protecting the oil’s fragile, delicious aromas.

Separating the Gold

After the oil droplets have coalesced, it’s time for the final separation. In the old days, this meant spreading the paste onto fiber mats, stacking them high, and using a hydraulic press to literally squeeze out the liquid.

Today, most mills use a centrifuge. This machine spins the paste at astonishing speeds, using centrifugal force to neatly separate the three components according to their density:

- Olive Oil: The lightest of the three, which is piped off first.

- Vegetable Water: The heavier water content from the fruit.

- Pomace: The solid leftovers—pits, skin, and pulp.

This entire modern journey, from crushing to spinning, is one continuous, unbroken flow. Crucially, it's all accomplished without any external heat or chemical solvents. It’s this meticulous care that separates a true extra virgin olive oil from common refined oils. You can learn more about the entire olive oil extraction process in our dedicated guide.

The global demand for this level of purity is surging. The tradition of cold-pressing has scaled up, with 58 countries across five continents now producing olive oil. In a recent record season, non-EU nations contributed nearly 40% of the 3.5 million-ton global production. The secret to this quality is keeping the process under 27°C, which preserves 75-80% of the olive's beneficial phenolic compounds—the very essence that gives the oil its magnificent flavor and protects it from oxidation.

This journey from grove to bottle is a beautiful testament to a simple truth: the best results come not from brute force, but from a gentle, respectful technique. It is a process designed to protect, not just extract, guaranteeing that every drop of oil is a true expression of the olive it came from.

How Temperature Shapes Flavor and Health Benefits

Why are the world's best olive oil producers so obsessed with a thermometer? Think of it this way: when you cook a delicate piece of fish with gentle, controlled heat, it becomes flaky, tender, and flavorful. But if you blast it with high heat, it turns tough, dry, and loses all its character. The very same law applies to making olive oil.

Temperature is the invisible hand that decides whether a bottle of olive oil becomes a vibrant, complex elixir or a flat, greasy cooking fat. Of course, cranking up the heat during extraction can squeeze out a few extra drops and increase yield. But that efficiency comes at a devastating cost. It systematically destroys the very compounds that give premium olive oil its soul.

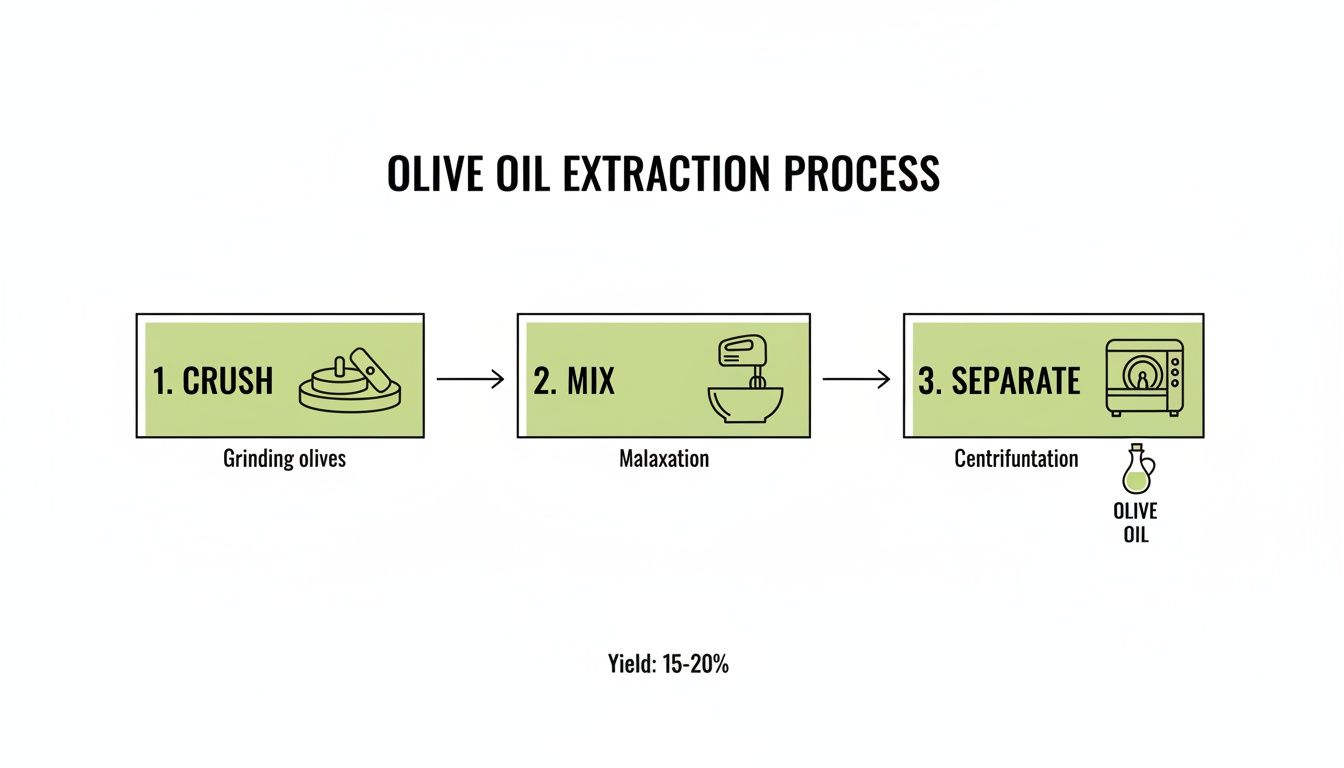

This simple infographic illustrates the modern cold-pressing journey, where maintaining a low temperature is non-negotiable at every stage.

From the initial crush to the final spin in the centrifuge, every step is managed with one goal in mind: to shield the oil's fragile character from heat.

The Heroes of Olive Oil: Polyphenols

The real magic inside a bottle of world-class extra virgin olive oil lies in its polyphenols. These are potent, naturally occurring antioxidants that serve as the olive’s own immune system. When we consume them, they lend us their protective powers. The entire purpose of the olive oil cold pressing method is to keep these heroes intact.

One of the most celebrated of these compounds is oleocanthal. If you’ve ever tasted a superior oil and felt a distinct, peppery sensation in the back of your throat, you have met oleocanthal. That feeling is not a flaw—it is the unmistakable signature of a fresh, powerful oil. This specific polyphenol is a natural anti-inflammatory agent, and its presence is a direct result of gentle, low-temperature extraction.

High heat is the sworn enemy of polyphenols. It causes them to oxidize and break down, effectively erasing the oil’s most profound health benefits before it ever reaches the bottle.

Keeping the olive paste below that sacred 27°C (80.6°F) threshold ensures that oleocanthal and other valuable compounds like hydroxytyrosol and oleuropein are preserved. This is precisely what elevates olive oil from a simple cooking ingredient into a genuine tool for wellness. The connection is direct and undeniable: cold pressing protects these compounds, resulting in an oil that is both richer in flavor and vastly better for your health.

A Tale of Two Flavors

The difference temperature makes is not some abstract concept measured in a lab; it’s something you can taste instantly. The flavor profiles of cold-pressed oil versus its heat-treated counterparts are worlds apart.

A true cold-pressed extra virgin olive oil sings with life. Its aroma might transport you to a field of freshly cut grass, a grove of green almonds, or a garden of artichokes. On the palate, it delivers a complex, harmonious balance of three key positive attributes:

- Fruitiness: A fresh, aromatic quality that recalls the living olive fruit itself.

- Bitterness: A desirable trait, often tasted on the sides of the tongue, which signals freshness and a high polyphenol count.

- Pungency: That peppery kick in the throat, the calling card of oleocanthal.

In stark contrast, oil extracted with heat tells a much sadder story. The delicate, volatile compounds that create those beautiful aromas are the first casualties. What’s left behind is often described as flat, greasy, or even rancid. The vibrant, living character is gone, replaced by a blandness that does nothing to elevate your food. If you're curious about how heat affects oil in your own kitchen, it's worth understanding the olive oil smoke point and why quality matters so much.

Ultimately, the choice to cold press is a choice for integrity. It’s a commitment to delivering an honest product that reflects the true nature of the olive—a fruit bursting with flavor, aroma, and life-giving nutrients.

Decoding Labels: Cold Pressed vs. Other Methods

Walking down the olive oil aisle can feel like navigating a minefield. You are confronted with a wall of bottles shouting terms like 'cold pressed,' 'extra virgin,' and 'light,' and it's nearly impossible to know what truly matters. Let's cut through the confusion and draw a bright line between the gold standard—cold pressing—and other methods designed for quantity, not quality.

Think of a 'cold pressed' label as a solemn promise. It is a sign that the oil was handled with reverence, extracted using only mechanical means without the damaging influence of heat. This gentle process protects the oil's natural flavors and potent nutrients. Its modern counterpart, 'cold extracted,' means the exact same thing but refers to the use of a centrifuge instead of a traditional press. Both paths lead to the same glorious destination: a superior oil.

The Problem with Heat and Shortcuts

So, what happens when producers prioritize wringing more oil from each olive? They crank up the heat. This method, known as hot pressing, undeniably boosts the yield, but it comes at a terrible price.

Heat demolishes the delicate antioxidants and aromatic compounds that give a premium oil its character and health benefits. The result is a flat, sometimes greasy oil that lacks the vibrant, peppery kick you expect. It is a classic industrial shortcut that sacrifices everything that makes olive oil special in the first place.

The Industrial Extreme: Solvent Extraction

At the very bottom of the quality ladder lies solvent extraction. This industrial process is typically reserved for the leftover olive pulp, or pomace, after the first pressing is complete. It is a method designed to squeeze out every last possible drop of oil, no matter the cost to quality.

The pomace is washed with chemical solvents, most often hexane, which dissolves any remaining oil. The solvent is then boiled off, leaving behind a low-grade, tasteless oil. This product must be heavily refined just to be made edible and is usually sold as 'pomace oil' or blended into generic 'olive oil.'

To verify that "cold pressed" claims are accurate, producers often rely on specialized oil laboratories. This scientific analysis ensures the promise on the bottle matches the quality inside.

Let's break down these methods side-by-side to make the differences painfully clear.

Olive Oil Extraction Methods Compared

The journey from olive to oil can take a few very different paths. The table below compares the three main extraction methods, showing how the process directly impacts the final product's quality, flavor, and nutritional value.

| Extraction Method | Process & Temperature | Resulting Oil Quality | Flavor & Aroma Profile | Nutrient Retention |

|---|---|---|---|---|

| Cold Pressing | Mechanical extraction below 27°C (80.6°F) with no chemicals. | Highest quality (Extra Virgin). | Complex, fruity, grassy, peppery. | Excellent retention of polyphenols & vitamins. |

| Hot Pressing | Mechanical extraction with added heat, often exceeding 50°C (122°F). | Lower quality, often requiring refinement. | Flat, bland, sometimes greasy or burnt. | Poor retention; most beneficial compounds are destroyed. |

| Solvent Extraction | Chemical process using solvents like hexane on leftover pulp (pomace). | Lowest quality (Pomace Oil). | Odorless and flavorless; must be refined to be edible. | Negligible; virtually all natural nutrients are stripped away. |

As you can see, the method is everything. Knowing these distinctions empowers you to look past the marketing slogans and choose an oil with confidence. The words on the label tell the whole story of how that oil was made, what it will taste like, and what it can do for your health.

For a deeper dive, check out our complete guide to reading an olive oil label. This knowledge is your best tool for bringing home an oil that will genuinely elevate your cooking and support your well-being.

How to Buy and Taste True Cold-Pressed Olive Oil

Now you know the secret that separates a genuine cold-pressed olive oil from the pretenders. But all that knowledge is just theory until you put it into practice. Tasting is where the truth is revealed—where you learn to trust your own senses to identify the real thing.

Once you can decipher the secret codes on a superior bottle, navigating the store aisle becomes simple. Better yet, learning to taste oil like an expert transforms you from a mere shopper into a true connoisseur, someone who can recognize the vibrant life locked inside a truly great oil.

Your Checklist for Buying Better Oil

Before you ever twist the cap, the quest for quality begins at the shelf. You must not be swayed by a pretty label or a romantic-sounding Italian name. Instead, you must become a detective, searching for the vital clues that point to a fresh, authentic, and well-protected oil.

-

Look for a Harvest Date: This is the single most important piece of information on the bottle. Olive oil is not like wine; it is a fresh fruit juice that begins to fade the moment it’s made. You want the most recent harvest date you can possibly find, ideally within the last year.

-

Choose Dark Glass or Tins: Light is one of olive oil's greatest enemies. An opaque, dark bottle or a metal tin is your best defense, shielding the delicate oil from the light damage that can quickly turn it rancid. See-through glass bottles? That's a giant red flag.

-

Seek Out Seals of Origin: Keep an eye out for certifications like PDO (Protected Designation of Origin) or PGI (Protected Geographical Indication). These seals are your guarantee that the olives were grown and the oil was produced in a specific region, which means a higher level of accountability and quality control.

How to Taste Olive Oil Like a Professional

Once you’ve brought a promising bottle home, it’s time for the moment of truth. Professional tasters never use bread; they taste the oil straight to experience its pure, unadulterated character. You can do the exact same thing with this simple, three-step ritual.

-

Warm and Swirl: Pour about a tablespoon of oil into a small, clean glass—a wine glass or even a shot glass works perfectly. Cup the glass in one hand and cover the top with your other to trap the aromas. Gently swirl the oil for about a minute. The warmth from your hand is just enough to release its fragrant compounds.

-

Smell Deeply: Now, uncover the glass, bring it right to your nose, and take a deep, deliberate sniff. What do you smell? A great cold-pressed oil should smell fresh and alive. You might detect notes of freshly cut grass, green apple, tomato leaf, or even banana. If it smells waxy, musty, or like nothing at all, it's a dead giveaway that the oil is old or of poor quality.

-

Slurp and Savor: Here comes the fun part. Take a small sip of oil and, as you do, suck in a bit of air. This "slurp" may feel strange, but it aerates the oil and spreads it across your entire palate, unlocking its full spectrum of flavors.

As you let the oil linger, pay attention to three key sensations. A truly exceptional extra virgin olive oil always strikes a balance between fruitiness, bitterness, and pungency.

A bitter note on your tongue and a peppery kick in the back of your throat are not flaws—they are the hallmarks of a fresh, healthy oil bursting with polyphenols. That little tickle that makes you want to cough is the calling card of oleocanthal, a powerful antioxidant that can only survive a true cold pressing. It’s the ultimate sign that the oil is the real deal.

To take your skills to the next level, you can explore detailed guides on how to taste olive oil and really start to develop your palate.

Busting a Few Olive Oil Myths

Walk down any grocery store aisle, and you'll be met with a wall of olive oil choices, along with a ton of marketing jargon and long-standing myths. It’s easy to get confused. These misconceptions don’t just get in the way of enjoying great oil; they can lead you to buy products that aren't what they claim to be.

Let's cut through the noise and tackle some of the biggest myths head-on. With the real story in hand, you can shop, cook, and taste like a pro.

Myth 1: You Can’t Cook with Extra Virgin Olive Oil

This is perhaps the most persistent and damaging myth of all. The claim is that EVOO has a smoke point too low for cooking, but this is simply untrue. A high-quality oil made through proper olive oil cold pressing will have a smoke point somewhere between 190–215°C (375–420°F).

Let's put that in perspective with everyday cooking temperatures:

- Sautéing and pan-frying? Usually done around 120°C (250°F).

- Deep frying? Most recipes call for 160–180°C (320–350°F).

- Baking? You’re typically not going above 200°C (400°F).

As you can see, a good EVOO can handle the heat just fine. In fact, its high concentration of stable antioxidants makes it one of the most resilient cooking fats available, protecting it from breaking down when heated. So go ahead and sear, sauté, and roast with it. You absolutely can—and should!

Myth 2: “Light” Olive Oil Means Fewer Calories

The word "light" on an olive oil bottle is a clever marketing trick that has nothing to do with calories or fat. All olive oil, whether it’s extra virgin or a refined "light" version, contains the same caloric value: about 120 calories per tablespoon.

So, what does "light" actually mean? It refers to the flavor and color. These oils have been intensely refined and filtered to strip out almost all of their natural character, leaving behind a neutral-tasting, pale yellow oil. They are a world away from the complex, vibrant flavors you get from a true cold-pressed extra virgin olive oil.

The "light" label is a classic marketing play targeting health-conscious shoppers. It’s a trick—it describes the oil's mild taste, not its nutritional content.

Myth 3: Italian Olive Oil Is Always the Best

Italy has a legendary, well-deserved reputation for producing phenomenal olive oils. But that fame has a dark side. A great deal of the "Italian" oil you find on store shelves isn't what it appears to be.

Many large brands simply import massive quantities of oil from other countries—like Spain, Greece, or Tunisia—then blend and bottle it in Italy. This practice allows them to legally slap a "Bottled in Italy" or "Packed in Italy" label on the front, which many people understandably mistake for "Product of Italy."

The real lesson here is that quality trumps geography. Incredible cold-pressed oils are being made all over the globe, from California to Australia. Instead of just looking for an Italian flag, check for a harvest date, a specific producer, and protective dark glass. Those are the true signs of quality.

A Few Lingering Questions About Cold Pressing

Even after diving into the details, a few specific questions tend to pop up. Let's tackle some of the most common ones so you can feel completely confident when you're choosing, using, and storing your olive oil.

Is "First Cold Press" Better Than "Cold Press"?

You’ve probably seen "First Cold Press" on a label and thought it must be a step above the rest. The truth is, it's more of a romantic nod to the past than a modern-day quality indicator.

Back in the day, traditional hydraulic presses might have squeezed the olive paste a second time to get every last drop. But today’s equipment is far more efficient. Modern centrifugal machines get all the oil out in one single, continuous process. There is no second press.

So, while the term isn't technically incorrect, it's mostly for marketing. The real markers of quality to look for are the terms "cold pressed" or "cold extracted", always paired with the "Extra Virgin" classification. That's the combination that truly matters.

How Can I Be Sure My Oil Is Genuinely Cold-Pressed?

The single best guarantee you have is the "Extra Virgin" grade on the label. To legally qualify as extra virgin, an oil must be extracted mechanically below that strict temperature threshold. It’s the very definition of cold pressing.

But beyond the label, your own senses are an incredibly reliable guide.

A genuinely cold-pressed extra virgin olive oil smells alive and vibrant—like fresh-cut grass, green almonds, or even tomato leaf. The real tell, though, is the taste: a distinct, peppery sensation that catches in the back of your throat.

That satisfying little kick is from oleocanthal, a potent polyphenol that simply cannot survive high-heat extraction. It is the authentic signature of a carefully made, high-quality oil.

Does Cold Pressing Change How I Should Store My Oil?

Yes, and this is a big one. The gentle process that works so hard to preserve all those delicate flavors and healthy compounds also makes the oil more fragile. Think of it this way: because all the good stuff is left in, it's more sensitive to its three biggest enemies: light, heat, and air.

To protect the quality you paid for, just follow a few simple rules:

- Find a cool, dark home for your bottle, like a pantry or cupboard.

- Never store it next to the stove or on a sunny countertop.

- Get in the habit of sealing the cap tightly the second you're done pouring.

Treat it less like a shelf-stable cooking fat and more like a fresh-squeezed juice. Proper storage is the key to making sure that incredible flavor and all those health benefits last.

At Learn Olive Oil, we believe understanding the journey from the olive grove to your kitchen table is what transforms your appreciation for this liquid gold. Our expert guides are here to help you choose, taste, and enjoy the world's best olive oils with confidence. Discover the World of Premium Olive Oil and elevate your culinary experience.

Leave a comment