At its heart, the process of extracting olive oil is a work of elegant, almost brutal simplicity: you crush fresh olives into a paste, then you force the oil to separate from the solids and water. While technology has sharpened the tools over centuries, the fundamental mission has never wavered—to liberate the precious, liquid gold trapped deep inside the fruit.

From Olive Fruit to Liquid Gold: An Overview

Before a bottle of true extra virgin olive oil ever graces your pantry, it has already survived a perilous journey. It is nothing short of a transformation, turning a bitter, unpalatable fruit into a treasure of the kitchen. This process is a masterful blend of ancient tradition and relentless modern precision—and it is a frantic race against the clock to capture the absolute peak of flavor and nutritional power.

The entire journey from the grove to the bottle must be executed with blinding speed. It begins with harvesting the olives at their fleeting moment of perfect ripeness and rushing them to the mill to prevent the fatal touch of oxidation. Once they arrive, they’re washed and then crushed—pits and all—into a thick, astonishingly fragrant paste.

The Secret of Malaxation

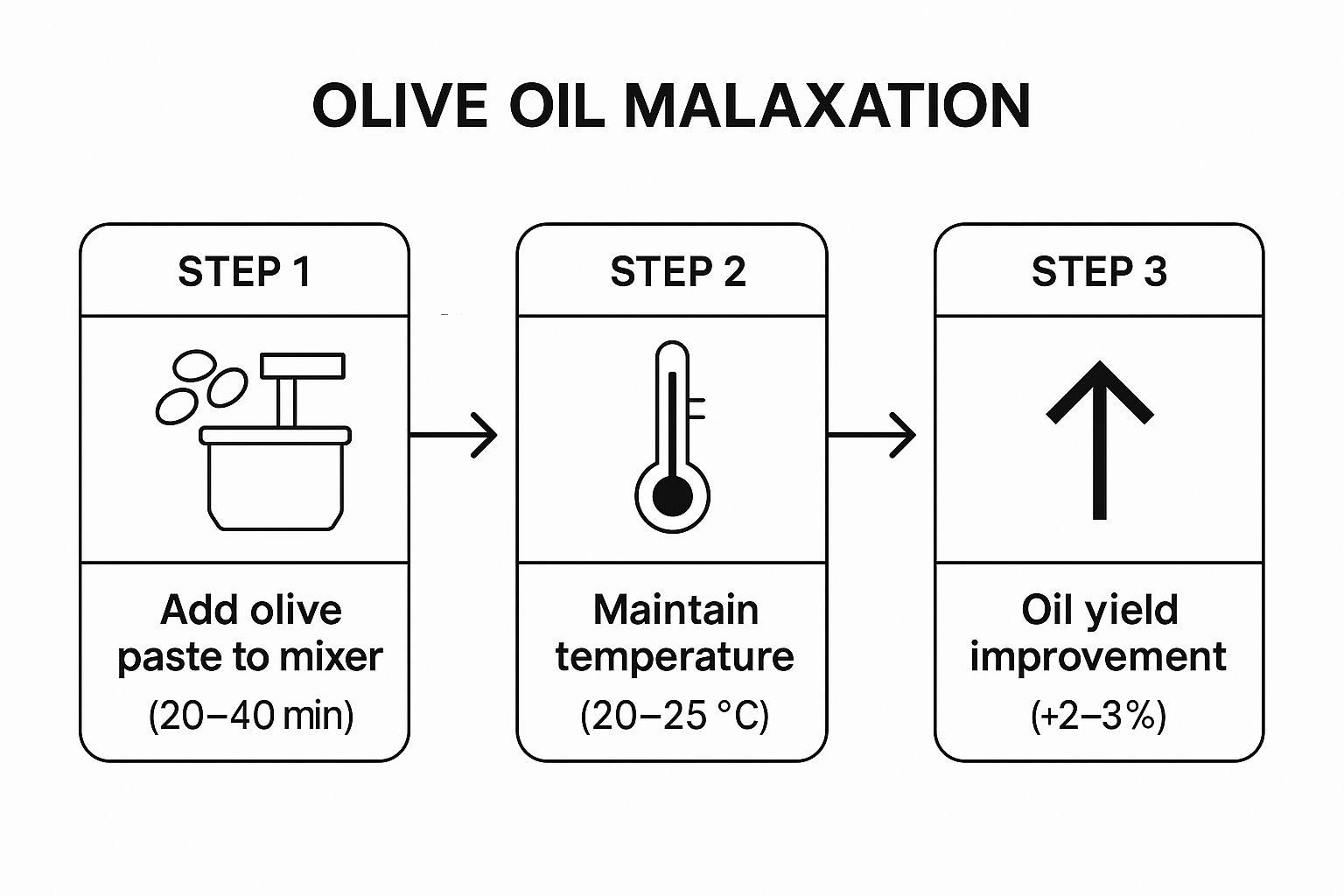

What comes next is a critical, and often misunderstood, step called malaxation. The olive paste is gently, hypnotically, and slowly mixed for about 20-40 minutes. This is not for show; this slow churning coaxes the tiny, microscopic oil droplets to abandon their solitary existence and band together, boosting the final yield by as much as 10-15%.

This is where a master miller's touch truly earns its keep, as they can subtly influence the oil's final character. The modern centrifugal extraction that follows is brutally efficient, achieving yields of around 20% oil relative to the olive's total weight. You can discover more about the different methods and eye-opening production figures in this detailed report on global practices.

To finish, a powerful centrifuge spins the paste at incredible speeds, surgically separating the pure, golden oil from the pomace (the solids) and water. Every single moment in this journey matters, and it is this fanatical attention to detail that separates a truly exceptional oil from a merely average one.

The Critical Race From Harvest To Mill

The soul of an exceptional olive oil is not forged in the mill—it is captured in the grove. From the very instant an olive is plucked from its branch, a clock begins to tick with ferocious intent. This is not just farming; it is a desperate race against time where every minute decides if the final product will be liquid gold or just another forgotten bottle on the shelf.

Picking the olives at precisely the right moment is a high-stakes gamble. Go too early, and you’ll get a fiercely bitter, grassy oil with a frustratingly low yield. Wait just a day or two too long, and the fruit surrenders a flat, lifeless oil that’s already on its way to becoming rancid. The true art lies in hitting that perfect, fleeting window of opportunity.

Hand-Picked vs. Machine Harvested

The way olives are picked also tells a compelling story. Careful hand-picking, while agonizingly slow and expensive, is gentle and protects the delicate fruit from the slightest bruise. On the other hand, mechanical shakers offer breathtaking efficiency, an absolute necessity for the colossal scale of modern production.

The best producers I know treat the journey from the tree to the mill like a medical emergency. Getting olives processed within a few hours—not days—is non-negotiable for them. That speed is what stops oxidation in its tracks and locks in the precious polyphenols that define a world-class extra virgin olive oil.

The scale of this industry is truly staggering. Globally, we're talking about a massive operation, with total production hitting around 2.7 million tonnes in 2022. Spain, a true titan in the field, produced 665,709 tonnes from its 2.8 million hectares of olive groves.

To put that into perspective, in a region like Andalucía, a single large-scale mill can chew through up to 2,500 tonnes of olives every single day. You can get more fascinating insights on the global olive oil market at Certified Origins.

Ultimately, a swift, merciless trip to the mill is what separates the good from the great. To truly grasp this first crucial battle, you might want to explore our deep dive into the different olive oil harvesting methods. It's this immediate, decisive action that preserves the fresh, vibrant character we all crave.

Inside The Mill: Crushing And Malaxation

Once the freshly picked olives arrive at the frantoio—the Italian term for an oil mill—the real magic begins. This is where the solid fruit starts its transformation into liquid gold. The first and most dramatic step is the crush. Here, the entire olive, from the skin and flesh right down to the pit, is pulverized into a thick, brilliantly colored paste.

Historically, this was accomplished with massive, slow-turning granite millstones. While beautiful to watch, most modern mills now rely on stainless-steel hammer mills. These powerful machines work much faster and, crucially, grant the miller incredible control over the process, especially when it comes to managing the enemy: temperature.

The Gentle Art Of Malaxation

After crushing, the vibrant olive paste moves on to what is arguably the most critical and misunderstood stage of the process: malaxation. Think of it less as simple mixing and more like a slow, deliberate persuasion.

This gentle churning, which typically lasts anywhere from 20 to 40 minutes in a large steel tank, has one primary goal. It coaxes the tiny oil droplets released during crushing to join forces, forming larger drops that are much easier to separate from the solid fruit matter and water. This is where the oil’s complex flavors and aromas are truly born.

A great miller's intuition is indispensable here. They are constantly monitoring the paste, balancing time against temperature. If the paste gets too warm, you might extract a little more oil, but you'll cook off all the delicate, peppery aromas that define a premium product. If it's too cool, you won't get a good yield, leaving precious oil trapped in the pulp.

This precise temperature control is the secret weapon behind high-quality olive oil. To be classified as "extra virgin," the olive paste must stay below 27°C (80.6°F) from start to finish. This is the entire basis for the "cold extraction" method. You can dive deeper into why this temperature is so vital by reading our guide on what "first cold-pressed" olive oil truly means. Keeping things cool is the only way to preserve the oil's full flavor profile and its healthy polyphenols.

The Moment Of Separation: Releasing The Oil

https://www.youtube.com/embed/Hz0QlRcnyio

After the malaxation phase, the olive paste is ready, and it is time for the miracle to happen. This is the crucial moment where we finally separate the oil, and it's where modern technology has completely rewritten the rulebook. Forget the romantic image of old stone presses; today, it’s all about the clean, powerful, and surgical precision of a decanter centrifuge.

Think of a horizontal drum spinning at an unbelievable speed—thousands of rotations per minute. As the olive paste is fed into this machine, the sheer centrifugal force does all the work, separating everything by its density in an instant.

It’s a beautiful, physics-based process.

- The heaviest solids—the leftover bits of pit and pulp called pomace—are forced to the outer wall.

- The vegetation water, which is a bit lighter, forms a layer just inside that.

- And finally, at the very center, the lightest element of all collects: the pure, vibrant olive oil.

From there, it's carefully piped away, ready for the next step. The efficiency of this separation is heavily influenced by the previous malaxation step, where time and temperature set the stage for how much oil can actually be liberated.

As you can see, you could crank up the heat to get a slightly higher yield, but any seasoned producer will tell you that's a fool’s bargain. You would be sacrificing the delicate aromas and flavors, a trade-off that simply is not worth it for a premium oil.

Why The Centrifuge Reigns Supreme

To truly appreciate the modern centrifuge, it helps to understand what it replaced. The traditional press and the modern decanter centrifuge are worlds apart in how they extract olive oil, with each method leaving a distinct mark on the final product.

Olive Oil Extraction: A Modern Vs Traditional View

| Attribute | Traditional Pressing | Modern Centrifugation |

|---|---|---|

| Process | Olive paste is spread on fiber mats, which are stacked and pressed to squeeze out liquid. | Paste is spun at high speed in a decanter, separating oil, water, and solids by density. |

| Efficiency | Slower and more labor-intensive. Can leave a higher percentage of oil behind in the pomace. | Highly efficient and fast, extracting a greater percentage of oil from the paste. |

| Oxygen Exposure | High. The paste is exposed to air on the mats, which can lead to rapid oxidation. | Minimal. The process occurs in a sealed, continuous-flow system, protecting the oil. |

| Hygiene | The fiber mats are difficult to clean perfectly, posing a risk of fermentation or off-flavors. | The stainless steel centrifuge is easily cleaned, ensuring a highly sanitary process. |

| Final Oil Quality | Can produce good oil, but the risk of defects from oxidation and contamination is much higher. | Consistently produces cleaner, fresher, and more stable oil with a longer shelf life. |

The old way of pressing the paste between fiber mats was not only messy and slow but also exposed the oil to its greatest enemy: oxygen. The centrifuge is a closed, airtight system. This means it’s faster, far more hygienic, and critically, it keeps oxygen away from the oil. This clean separation is a primary reason why modern extraction produces superior extra virgin olive oil.

You can learn more about what makes olive oil truly "virgin" and the punishingly strict standards it must meet.

But we're not quite done. For absolute clarity and stability, the freshly separated oil often gets a final "polishing." It's sent through a second, vertical centrifuge that spins even faster, wicking away the very last traces of water and any microscopic sediment. What emerges is pristine, brilliant oil, perfectly ready for safekeeping.

Preserving Liquid Gold: Filtration and Storage

The work doesn't stop once the centrifuge has done its job. In fact, one of the most vital stages is just beginning: protecting the fragile flavors and potent health benefits of the freshly extracted oil. This brings us straight to a major debate in the olive oil world—to filter or not to filter?

You might see hazy, unfiltered oil and believe it looks more authentic or rustic. The truth is, most top-tier producers choose to filter their oil, and for a very good reason. That cloudiness is not just character; it is made up of residual water and tiny olive particles. Over time, these solids will ferment and spoil the oil, dramatically cutting its shelf life short.

Filtration neatly removes these impurities. The result is a brilliant, stable oil that holds onto its fresh, vibrant character for much longer. For a deeper dive, our guide on filtered or unfiltered olive oil breaks down the pros and cons.

Guarding Against the Elements

Once filtered, the oil faces three sworn enemies: oxygen, light, and heat. Exposure to any one of them will degrade the oil, creating foul off-flavors and destroying the very polyphenols that make it so healthy.

This is why premium producers act fast. They immediately transfer the fresh oil into vast, temperature-controlled stainless steel tanks. To go a step further, many will even flush the headspace in the tank with an inert gas like nitrogen, which displaces all the oxygen and completely halts oxidation.

"Olive oil is not like wine. It doesn’t improve with age. The faster you can make it into oil, the better it is."

That same principle holds true once you bring a bottle home. How you store your olive oil makes all the difference in preserving its quality from the first pour to the last drop.

Here is what you must do:

- Choose the right container: Always opt for oil sold in dark glass bottles or tins. Clear glass is a glaring red flag, as it offers zero protection from light damage.

- Find a cool, dark place: Your pantry or a cabinet is the perfect spot. Keep it away from the windowsill and, most importantly, away from the heat of your stove.

- Keep it sealed: Get in the habit of tightening the cap right after you use it. This simple act keeps oxygen out and the fresh flavor in.

Following these simple rules ensures all the hard work that went into that bottle—from the olive grove to the mill—was not in vain.

Answering Your Olive Oil Questions

Even after seeing how olive oil is made, a few questions always surface. These are the details that really matter, the kind of knowledge that turns you from a casual buyer into someone who truly understands what is in the bottle. Let's tackle the most common ones.

What Does "Cold-Pressed" Actually Mean?

You see "cold-pressed" on labels all the time, but frankly, it’s a ghost term these days. It is a carryover from the old days of traditional hydraulic presses. The term that truly matters for modern production is "cold extraction."

This is your guarantee that the olive paste was kept below a strict temperature ceiling of 27°C (80.6°F) during the entire process, especially the crucial malaxation stage. Why this obsession with temperature? Heat is the mortal enemy of quality. It murders the delicate aromas, ruins the flavor, and destroys the very antioxidants you’re paying for.

By definition, any legitimate extra virgin olive oil must be a product of cold extraction. It is non-negotiable.

While the details of extraction can seem technical, they all point back to a single goal: protecting the natural quality of the fruit. Once you grasp that, finding a great bottle of olive oil becomes a whole lot easier.

Why Is Everyone in Such a Rush After the Harvest?

It helps to think of an olive just like any other fresh fruit, say an apple or a banana. The moment it leaves the tree, the clock starts ticking. Oxidation and fermentation begin almost immediately, and they are merciless.

If olives are left to sit in sacks or bins for even a day, you're asking for trouble. Defects start to develop, which can lead to musty, fusty, or winey flavors in the oil. The best producers are absolutely fanatical about this. They get their olives from the branch to the mill within just 4 to 12 hours of being picked. This race against time is what locks in that fresh, peppery bite and high polyphenol count that great extra virgin olive oil is known for.

Should I Buy Unfiltered Olive Oil?

Not unless you plan on using it up very, very quickly. Unfiltered oil, which you might see marketed as olio nuovo ("new oil"), certainly has a certain rustic charm. That cloudy appearance, however, is caused by tiny suspended particles of olive fruit and water.

Those very same particles are what cause the oil to go bad so much faster. Filtration is not a cheat or a shortcut; it is a critical step for ensuring the oil remains stable. It removes the sediment that will inevitably lead to rancidity. If you’re buying a bottle you expect to last for a few months, a well-made filtered oil is always the smarter bet. A clear oil is also one of the first things to look for when you're learning how to spot fake olive oil.

At Learn Olive Oil, we're dedicated to helping you discover the world of premium olive oil with confidence. https://learnoliveoil.com

Leave a comment