Understanding What Makes Exceptional Olive Oil

This screenshot from Wikipedia's Olive Oil page gives you a great visual of the different olive varieties and what they’re used for. Look at the sheer variety of olives grown worldwide—the range of colors and sizes is amazing! This visual diversity really hints at the incredible range of flavors and characteristics possible in the final olive oil, all depending on the olive variety and how it's handled.

Believe me, the difference between supermarket olive oil and a truly exceptional oil isn't just marketing hype. It's a deep respect for the delicate dance of each production stage, from the olive grove all the way to the bottle. I’ve talked to mill operators who have dedicated their lives to perfecting their craft. They've shown me how crafting outstanding oil involves a constant interplay of time-honored traditions and precise, on-the-fly adjustments. These master producers aren’t just following a recipe; they're working with nature—tweaking their techniques based on the weather, the olive variety, and even the humidity that day.

For example, timing is everything. Harvest just a few days too early or too late, and the flavor profile changes dramatically. Experienced growers will taste olives constantly throughout the day, searching for that perfect moment of peak sugar content, just before the fruit’s vibrant character starts to fade. This window can be incredibly short, and the weather can throw a real wrench in the works, changing the ideal harvest time unexpectedly.

The Importance of Early Stages

The very first steps—harvesting, sorting, and cleaning—are absolutely foundational to the final quality. They’re the building blocks of a premium product. The olive harvest itself typically happens between October and December. Once harvested, the olives are sorted and cleaned before being crushed or pressed to extract that liquid gold. Learn more about current olive oil trends and production forecasts here. This is a great resource for understanding how outside factors, like worldwide production and market demand, can influence the final product and how readily available it is. Knowing these market forces is just as important as mastering the production techniques themselves.

This focus on precision continues throughout the entire process. Artisan producers are obsessed with details that might seem insignificant—like the precise temperature during malaxation (mixing the crushed olive paste). But these subtle nuances have a huge impact on the final aroma, flavor, and overall quality. These small choices, taken together, are what separate truly special olive oil from just another bottle on the grocery store shelf. They're what elevate simple ingredients into a remarkable culinary experience.

Let's take a look at global olive oil production to get a sense of the scale of this industry:

To give you a better understanding of the global landscape, I've put together this table:

Global Olive Oil Production by Country

Comparison of major olive oil producing countries and their annual production volumes

| Country | Annual Production (tons) | Market Share (%) | Quality Grade Focus |

|---|---|---|---|

| Spain | 1,600,000 (estimated) | ~45% | Extra Virgin, Virgin |

| Italy | 400,000 (estimated) | ~12% | Extra Virgin, PDO/PGI |

| Greece | 300,000 (estimated) | ~9% | Extra Virgin, PDO |

| Tunisia | 250,000 (estimated) | ~7% | Virgin, Olive Oil |

| Turkey | 225,000 (estimated) | ~6% | Olive Oil, Virgin |

| Morocco | 175,000 (estimated) | ~5% | Virgin, Olive Oil |

| Portugal | 100,000 (estimated) | ~3% | Extra Virgin, PDO |

(Note: These figures are estimates based on recent harvest data and can vary year to year.)

As you can see, Spain is the undisputed leader in olive oil production, accounting for nearly half the global market. While other countries produce significant amounts, the quality grade focus varies. Many countries, like Italy, Greece, and Portugal, prioritize high-quality Extra Virgin and protected designation of origin (PDO) oils, while others focus on larger volumes of Virgin and standard Olive Oil grades. This table helps illustrate the diverse landscape of olive oil production and the emphasis different regions place on quality.

Reading the Signs for Perfect Harvest Timing

Harvesting is where the magic of olive oil production really begins. It’s not just about picking olives; it’s about understanding them. Trust me, it’s more nuanced than you might think. The harvest window, that perfect moment when the olives are just right, can be incredibly short – sometimes just a few days. I’ve seen seasoned olive growers taste olives multiple times throughout the same day, trying to pinpoint that peak sugar content. That's when you know it's go-time, the absolute best moment to capture the full flavor profile.

Visual Cues and the Art of Observation

Experienced olive oil producers develop an almost intuitive sense of when an olive is ready. They rely on visual cues, honed over years of working with the trees. They watch for the color to shift from green to a deep, almost purplish black. They’ll also check how easily the olives detach from the branches – a gentle tug is all it should take. Believe it or not, even the sound the olives make as they fall onto the collection nets can be a clue – a slightly duller thud indicates ripeness. These subtle indicators are like a secret language, understood by those dedicated to producing the finest olive oil.

It's all about the details! A small change in color, the soft tug of the fruit, the quiet sound of the olives hitting the nets—to the untrained eye, these may seem insignificant. But to the olive oil master, they reveal volumes.

Environmental Factors and Early Morning Harvests

Weather plays a big role in harvest timing. Rain, for example, can plump up the olives with water, which dilutes the oil. Temperature fluctuations also impact flavor. That's why you'll often see harvesting happening in the cool, early morning hours. Those lower temperatures help preserve the delicate volatile aromatic compounds – the ones responsible for those amazing fruity and peppery notes we love in high-quality olive oil. As the day heats up, those compounds can start to disappear.

Think of it like this: those volatile aromatic compounds are like tiny flavor fireworks waiting to explode on your palate. But if they get too warm, they fizzle out before they have a chance to shine. Early morning harvesting helps capture that firework display in every drop.

Orchestrating the Harvest: A Real-World Example

Picture a large olive grove, maybe hundreds of acres, with different olive varieties, each ripening at its own pace. Coordinating the harvest is a massive undertaking. I’ve witnessed firsthand how skilled producers manage this logistical feat. They direct teams to specific areas of the grove based on real-time assessments of olive readiness. It's like a carefully choreographed dance, ensuring that thousands of pounds of olives are harvested daily, each variety picked at the absolute perfect moment. This level of precision and attention is a hallmark of truly exceptional olive oil.

This kind of orchestration is crucial. Imagine the complexity: multiple crews, different olive varieties, a tiny harvest window, and the pressure to maintain quality. It’s a testament to the dedication and skill of these producers. They know that even a small slip-up can compromise the final product.

The Make-or-Break Hours After Harvest

The second those olives are off the tree, the countdown begins. The next few hours are absolutely critical for making top-notch olive oil. Seriously, this short window can make or break your whole batch. I've chatted with professional mill operators, and they all agree: this is where being super detail-oriented makes a huge difference, and cutting corners leads to big problems.

Sorting: More Than Just Removing the Bad Apples

Sorting isn't just about tossing out the obviously damaged olives. It’s about really understanding the fruit. You're looking for subtle things—tiny bruises, slight changes in color, even stems and leaves. These can all be signs of stress, early fermentation, or other issues that can mess with the flavor and quality of your oil. The pros can spot these tricky olives right away. They know even a few bad ones can affect the entire batch.

For example, a small bruise might not seem like much, but it could mean internal damage and off-flavors. Even a slight color variation could indicate uneven ripening, changing the oil’s chemistry and taste.

The Art of Washing and Temperature Control

After sorting, the olives get a gentle bath. This gets rid of dirt and anything else that shouldn’t be there, without hurting the delicate skin. The right washing technique is key—too rough, and you’ll damage the fruit; too gentle, and you might miss important contaminants. And temperature control? Absolutely crucial from the second those olives are picked. Heat can trigger unwanted chemical reactions, lowering the quality of the oil.

Think of it like fresh herbs—you wouldn’t leave them in the hot sun, right? Same goes for olives. This means keeping them cool the whole time, from harvest to milling. Many producers harvest early in the morning to avoid the heat and transport the olives in containers with good ventilation to prevent temperature buildup.

Maintaining Quality During Peak Season

Harvest season gets crazy. Tons of olives need to be processed quickly. But even with the pressure, the best producers never sacrifice quality. They stick to their strict sorting and washing routines, even when time is tight. They know that rushing these crucial steps will only result in a subpar product.

So how do they balance speed and quality? They invest in good sorting and washing equipment and train their teams to work quickly and precisely. They create smooth workflows that allow them to handle large quantities while still giving the olives the attention that makes truly great olive oil. It's about finding that sweet spot between speed and precision. That's why making olive oil isn't just about the technical process; it's also about the art of keeping quality high under pressure.

Mastering the Crushing and Malaxation Process

This is where olive oil production gets really interesting. It's the point where age-old traditions meet modern science. The crushing stage is a pivotal moment—months of work come down to this. Will you get liquid gold, or will disappointment crush your dreams (pun intended)? I've chatted with mill operators who use everything from ancient stone wheels to modern hammer mills, and honestly, each method has its own perks. It all depends on what you're going for and the kind of olives you're working with. Stone mills are slow and gentle, coaxing out delicate flavors. But, they're also time-consuming and don't yield as much oil. Hammer mills? Fast and efficient, but you have to manage the temperature carefully, or you'll damage the oil's nutritional goodness.

Crushing: The First Step

The crushing method you choose has a huge impact on the final product. Think of traditional stone wheels, often made of granite. They crush the olives slowly, releasing the oil gradually. This gentle approach minimizes heat, which helps preserve those volatile aromatic compounds—the secret behind complex flavors. Now, hammer mills are a different story. They're all about speed and efficiency, maximizing oil extraction. But, all that action creates more heat. This means you need precise control to avoid overheating the olive paste and ruining your oil's quality. Controlling paste consistency is also crucial, something you'll learn more about as we go.

Malaxation: The Gentle Art of Mixing

After crushing, the olive paste moves into the malaxation phase. A lot of people overlook this step, but trust me, it's essential. Malaxation is basically slowly mixing the paste. This encourages the microscopic oil droplets to join forces and form bigger ones, which makes extraction easier. Imagine gently persuading the oil to come out of its hiding spots within the paste. Rushing this step is a big no-no. Different olive varieties react differently to various malaxation techniques. And temperature control? Absolutely critical. Professional producers keep a constant eye on the temperature during this delicate process. Too hot, and you risk ruining the flavor and nutritional value of your oil. Too cold, and the oil won't separate properly.

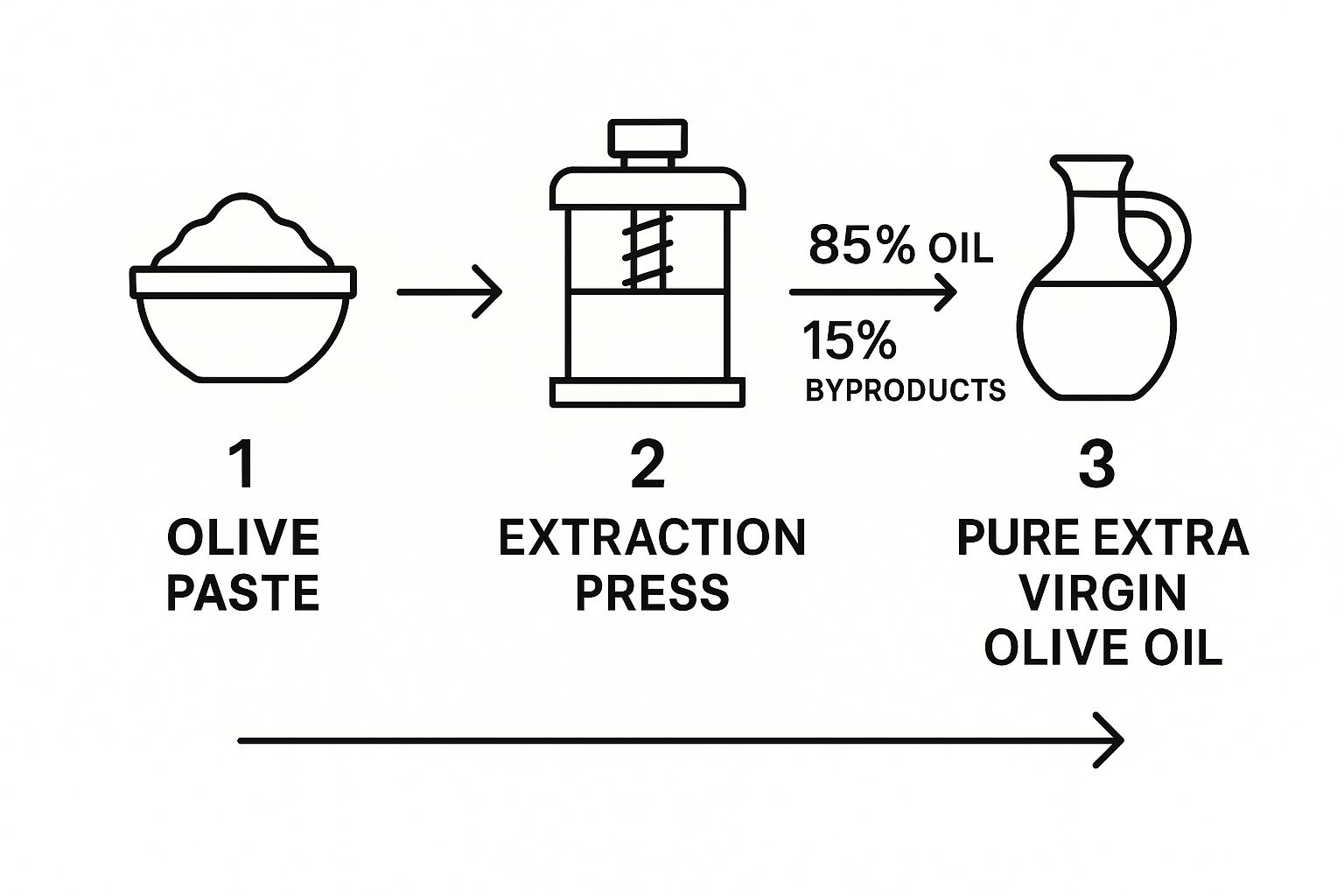

This infographic shows the journey from olive paste to pure extra virgin olive oil. It breaks down the extraction process into three main stages: input, separation, and output. Notice how the centrifugal separation stage yields roughly 85% oil and 15% byproducts. Modern extraction methods are remarkably efficient! This really highlights the precision involved in separating that precious oil from the other components of the olive paste while getting the most oil possible.

Let's talk about the different crushing methods. I've put together a table to help you compare them:

Crushing Methods Comparison

| Method | Extraction Rate (%) | Temperature Control | Flavor Impact | Processing Speed |

|---|---|---|---|---|

| Traditional Stone Mills | Lower (e.g., 60-70%) | Easier, lower temperatures | Preserves delicate flavors | Slow |

| Modern Hammer Mills | Higher (e.g., 80-90%) | More challenging, higher temperatures | Can impact delicate flavors if not managed carefully | Fast |

As you can see, traditional stone mills offer a gentler approach that preserves delicate flavors, but at the cost of extraction rate and speed. Modern hammer mills are much faster and more efficient, but require precise temperature control to protect those precious flavors.

Finding the Right Balance

The perfect malaxation time and temperature? It’s a moving target. It depends on the olive variety and the kind of oil you’re after. For example, robust olive varieties might need longer malaxation at slightly higher temperatures to bring out their full-bodied flavors. Delicate varieties, on the other hand, need shorter times and lower temperatures to preserve their subtle aromas. To get the oil profile you want, you need to keep a close eye on things throughout the malaxation process—constantly checking the paste's consistency, aroma, and temperature. This careful balancing act between time, temperature, and technique is something you develop over years of practice. It's what separates truly exceptional olive oil from the ordinary.

Separating Pure Gold From the Mix

What comes out of the olive press isn't ready for your kitchen table. It’s a mix of oil, water, and tiny bits of olive—kind of like a chunky, oily salad dressing. This mixture needs careful separation to get that beautiful, clear olive oil we all know and love. This separation process is where the real skill of an olive oil producer shines. It’s all about finding the right balance: removing impurities while preserving the delicate flavors and health benefits.

Traditional vs. Modern Separation

Traditionally, olive oil producers let gravity do the work. They would let the freshly pressed mixture sit, allowing the heavier olive particles and water to slowly sink to the bottom. It’s a slower method, but it’s incredibly gentle and helps preserve those subtle, fresh flavors.

Now, many producers use centrifuges. These machines spin the mixture at seriously high speeds, separating the oil much faster than gravity ever could. However, using a centrifuge requires careful calibration. Too much spinning, and you risk damaging the oil's delicate molecular structure. Think of it like steeping tea versus blasting it in a blender—the end result can be totally different.

Signs of Proper Separation and Troubleshooting

How can you tell when the separation is complete? Experienced producers can actually tell just by looking at the oil. It should be clear, bright, and free of any cloudiness or sediment. They’ll also look for signs of emulsification, which happens when the oil and water mix together and refuse to separate. This can occur if the olives weren't processed quickly enough after harvesting, or if the temperature wasn’t just right during the process.

Incomplete water removal can lead to a shorter shelf life and some unpleasant off-flavors. It's like trying to separate oil and vinegar in a salad dressing—sometimes they just don’t want to cooperate! I remember visiting a small, family-run mill in Italy that still uses the traditional settling method. They kept a close eye on their settling tanks, watching for a distinct line to appear between the oil and the water. They even showed me how tiny vibrations from nearby equipment could disrupt the settling process, so they’d carefully placed the tanks in a quiet corner of the mill.

Environmental Factors and Storage

Even the environment plays a surprising role in separation. Temperature fluctuations, humidity, and even vibrations can affect this sensitive stage. That’s why maintaining consistent temperature control during storage is so important. You wouldn't leave a fine wine in a hot car, right? Olive oil is similar – it needs a cool, dark place to preserve its quality and flavor.

Speaking of the market, the global olive oil industry has its share of peaks and valleys. You can find some interesting insights into olive oil market trends here. Just like the production process, the market is constantly changing. For example, in January 2025, Spain produced 344,530 tons of olive oil, contributing to a total of 1,234,568 tons. Sales that month, excluding imports, reached 116,104 tons, exceeding expectations partly due to increased demand from Italy after two disappointing harvests.

Proper handling through each stage, from harvesting to bottling, is crucial for the final product's quality and nutritional value. By understanding these details, producers can ensure they’re crafting the highest quality olive oil possible. This attention to detail is what truly sets exceptional olive oil apart. It's a testament to the art and science of a centuries-old tradition.

Protecting Your Liquid Investment Through Proper Storage

After months of hard work producing top-notch olive oil, you don't want to let it go to waste. Imagine spending hours on a painting only to leave it out in the rain! Olive oil is just as delicate. Proper storage isn’t just about keeping it fresh; it’s about preserving those amazing flavors and antioxidants that make it truly special. Let me share a few tips I’ve picked up along the way.

The Enemies of Olive Oil

Your olive oil’s biggest enemies? Light, heat, oxygen, and time. These guys work 24/7 to degrade the quality. Light can create weird off-flavors and even reduce the nutritional value. Heat speeds up oxidation, making the oil go rancid. Oxygen is another culprit in oxidation, and time itself just slowly diminishes those vibrant characteristics. Luckily, smart storage can help!

So what can we do? Let's dive into some strategies to mitigate these risks and keep your olive oil happy.

Storage Container Materials: Choosing Wisely

Your storage containers are your first line of defense. I’ve chatted with some award-winning producers, and they swear by stainless steel tanks for bulk storage. They're inert, so they won’t mess with the oil's chemistry, and they're easy to keep clean. For smaller amounts, dark glass bottles are fantastic. They block out light and keep everything stable. Steer clear of plastic for long-term storage. It can leach chemicals into the oil and let oxygen sneak in.

Now, what about temperature?

Temperature Control and Monitoring

Temperature is crucial. The sweet spot is between 57°F and 64°F (14°C and 18°C). Consistent temps keep those flavors intact and extend the shelf life. A temperature control system for your storage area is worth considering. Regularly check the temperature with a good thermometer. Small changes might not seem like much, but they add up over time. Think of it like storing fine wine – consistency is key.

Once you've got storage sorted, it's time to think about bottling.

Bottling Best Practices: Preserving Integrity

Bottling is the final step in protecting your precious oil. Nitrogen flushing gets rid of oxygen in the bottle, which really helps prevent oxidation. Filtration can be a bit controversial, but done right, it clears up the oil without removing the good stuff. Always use dark glass bottles and fill them completely to minimize air exposure.

Finally, let's talk quality control.

Quality Control: Ensuring Consistency

The best producers are obsessed with quality. They constantly test to make sure their oil meets their standards. Checking for acidity and peroxide values can tell you a lot about stability and quality. Regular testing will help you maintain that high quality that customers love, which in turn builds trust and strengthens your brand. This meticulous approach to storage sets the top olive oil producers apart. They know protecting their “liquid gold” is key to long-term success.

Your Path to Olive Oil Production Success

I've spent a lot of time talking with olive oil producers – some crushing it and some, well, not so much. Through those conversations, I've noticed some patterns, both in the challenges and the successes. I want to share those insights with you, offering practical advice, not just a bunch of technical mumbo-jumbo. This is about giving you the confidence to navigate each step of the process, from orchard to bottle.

Realistic Timelines and Coordination

Knowing how long each stage takes – harvesting, milling, pressing, clarifying, bottling – is key to smooth operations. Think of the olive harvest: that window of perfect ripeness might only last a few days. Having your team and equipment primed and ready is crucial. Even the time it takes from pressing to clarification can change depending on your method. Traditional settling? Much slower than centrifugal separation. Build that into your schedule. A realistic timeline prevents bottlenecks and ensures each step gets the attention it deserves.

Scaling: From Artisanal to Commercial

Whether you're dreaming of small-batch artisanal oils or aiming for large-scale commercial production, scaling up requires a plan. Equipment, for instance, is a big decision. A small stone mill might be perfect for capturing those unique, nuanced flavors in a boutique operation. But if you're aiming for higher volumes, a larger hammer mill might be a better fit. As you grow, efficient workflows and rock-solid quality control become even more important, ensuring every bottle maintains that same high standard, no matter the batch size. Think big-picture, even from the beginning.

Monitoring, Testing, and Troubleshooting

Knowing what to look for at each stage is like having a superpower. It's about empowering you to maintain quality. The color of the olives at harvest, the consistency of the paste during malaxation (that's the mixing stage), the clarity of the oil during separation – these are all valuable clues. Even simple tests – like tasting an olive for ripeness or checking the oil's acidity – can make a world of difference in consistency. And don’t underestimate troubleshooting. Knowing why something like emulsification happens during separation lets you fix it fast, preventing big losses.

Practical Implementation and Benchmarks

All this advice? It’s meant to be used. So, instead of just saying "monitor temperature," I’ll give you specific temperature ranges for optimal malaxation and storage. Clear benchmarks help you see your progress and celebrate those wins. Did your final product hit that target acidity level? Did you avoid emulsification during separation? These are the milestones that mark your journey toward olive oil success. Remember, every single step, from grove to bottle, contributes to crafting an oil you’ll be truly proud of.

Ready to embark on your own olive oil adventure? Learn more about producing premium olive oil at Learn Olive Oil.

Leave a comment