You can almost taste it, can't you? That rich, flavorful oil that elevates a simple piece of bread or a fresh salad into something truly special. But have you ever stopped to think about how that liquid gold gets from the olive grove into your bottle? The journey is a fascinating blend of art, science, and meticulous care.

At its heart, the best olive oil is simply the fresh-pressed juice of olives. Its ultimate quality isn't decided in a factory, but right at the moment the fruit is plucked from the tree.

From Olive Grove to Liquid Gold

Think about the difference between a glass of orange juice you squeeze yourself and the stuff from a carton. One is bright, alive, and bursting with the true essence of the fruit. The other, while technically still juice, often feels like a pale imitation. It's lost its nuance, its soul. High-quality olive oil extraction is all about capturing and preserving that vibrant, living soul.

This guide will take you on the complete journey, from the sun-drenched groves to the final bottled product. It's a process where ancient traditions shake hands with modern technology, and every single step matters immensely. The aroma, flavor, and health benefits of the oil you use are all determined long before it ever reaches a store shelf.

The Critical Stages of Extraction

Turning a bitter fruit into liquid gold isn't a single event but a series of precise stages. Each one has to be handled perfectly to protect the oil's integrity. Just one misstep can be the difference between a world-class extra virgin olive oil and something far less impressive.

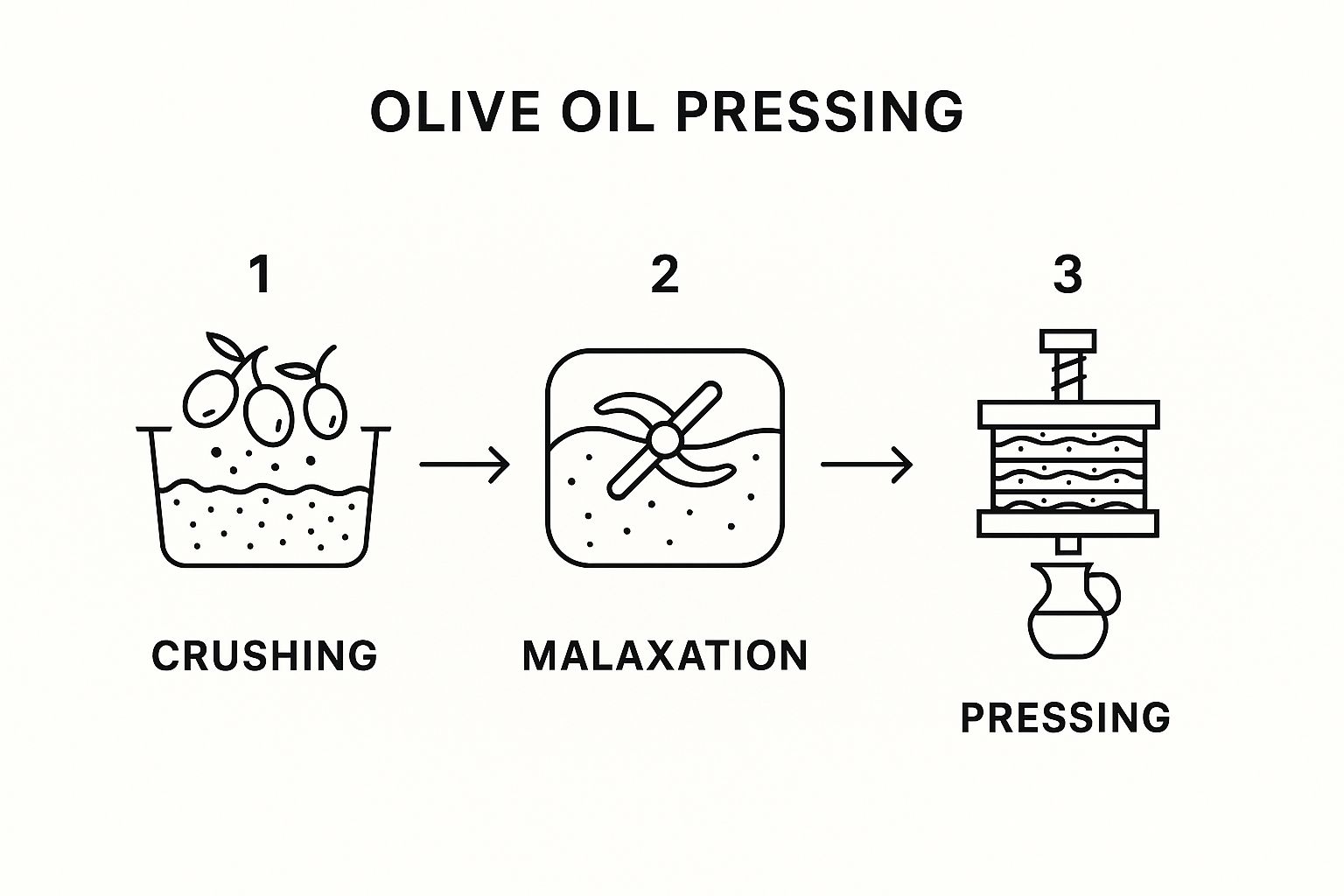

The main steps are:

- Harvesting and Transport: It all starts in the grove. Olives are picked at their peak ripeness and must be rushed to the mill—ideally within hours. This race against the clock prevents oxidation and fermentation, the two mortal enemies of great olive oil.

- Crushing and Milling: At the mill, the whole olives, pits and all, are ground into a thick, uniform paste. The idea is to break open the fruit's cells and start the process of releasing the precious oil.

- Malaxation: This is a fancy word for a crucial step: slowly and gently mixing the olive paste. Think of it as a delicate kneading process that encourages tiny oil droplets to find each other and merge into larger ones, making them much easier to extract.

- Separation: This is the moment of truth, where the pure oil is finally parted from the solid pomace (the leftover pits and pulp) and the vegetable water. Modern mills use a powerful centrifuge, which spins the paste at incredible speeds to separate everything based on its density.

Every step in the olive oil extraction process is a decision point that impacts quality. From the temperature during malaxation to the speed of the centrifuge, producers are constantly balancing yield against the preservation of delicate flavors and healthful compounds.

When you understand this process, you start to see why true extra virgin olive oil is so remarkable. It's not just another cooking fat; it's the carefully preserved juice of a fruit, captured at its absolute peak. As we dig deeper into how this ancient craft has evolved, you’ll gain a whole new appreciation for what’s really inside that bottle.

The Ancient Roots of Olive Oil Pressing

To really get a feel for today’s olive oil extraction technology, you have to look back. The story of olive oil isn't just about food; it's woven into the very fabric of human history, starting in the ancient Mediterranean where making it was a true test of ingenuity and raw physical strength.

The very first methods were simple, but they worked. Picture massive stone wheels, some weighing several tons, being dragged by donkeys or pushed by laborers to crush olives in a stone basin. This grueling work created a thick olive paste, but that was just the first step in a long, demanding process.

Next, workers would meticulously spread this paste onto woven fiber mats, usually made from hemp or coconut fibers. They’d stack these mats one on top of the other, creating a tower of paste-filled discs. Then came the pressure. A heavy beam or a screw press was used to squeeze the stack, forcing out the precious liquid—a mixture of oil and water.

The Rise of Hydraulic Pressure

For centuries, the basic idea of applying pressure didn't change much. The real innovation was in finding better ways to create that force. The big leap came with the Industrial Revolution and the invention of the hydraulic press. For olive oil makers, this was a game-changer.

Instead of relying on pure muscle power, hydraulic systems used fluid to generate immense force with far less effort. Mills could suddenly process much larger quantities of olives, and do it faster than ever before. While these machines were a world away from the old stone wheels, they still operated on the same core principle: squeezing the olive paste to get the liquid out.

But this traditional pressing method had its problems:

- Heat Generation: All that friction and pressure created heat. This was bad news for the oil, as heat damages its delicate flavors and degrades its healthy compounds.

- Oxidation: The fiber mats exposed the olive paste to air for long periods. This led to oxidation, which could introduce off-flavors and shorten the oil's shelf life.

- Labor Intensive: Even with hydraulic help, the process was still physically demanding and slow, putting a cap on how much oil a mill could produce.

The constant search for better quality and higher yields has always been the engine of innovation in this industry. The flaws of traditional pressing directly fueled the quest for a new method—one that could protect the oil's integrity without all the squeezing.

A Growing Global Appetite

The world’s increasing demand for olive oil has been a major catalyst for this evolution. Production has been on a steady climb for decades, really taking off in the mid-1990s. Global output first shot past 2.5 million tons in the 1996/1997 season and broke the 3 million ton barrier just a decade later. For the past 50 years, European Union countries have dominated the scene, producing about 76% of the world's supply. If you're interested in the numbers, you can dive deeper into these trends in this detailed handbook on olive oil.

This whole journey, from ancient stone wheels to powerful hydraulic systems, was really just setting the stage for the next great leap. The industry's drive to overcome the quality issues tied to pressing would ultimately lead to the modern centrifuge, a machine that completely redefined how this liquid gold is made.

Inside a Modern Olive Mill: The Centrifuge Process

Walk into a modern olive mill today, and you’ll find a world away from the romantic image of old stone wheels. It’s all gleaming stainless steel and precision engineering now. The traditional presses have been replaced by a far more efficient method: centrifugation. This is the workhorse of modern olive oil extraction, a system that uses incredible force to separate the oil from the fruit.

It all starts with the olives—pits, pulp, and all—being fed into powerful hammer mills. These machines instantly crush the fruit into a thick, uniform paste. The goal here is simple but critical: rupture the cell walls within the olive to get the oil ready for release. It’s a fast, aggressive start to what becomes a much more careful and deliberate process.

From the mill, the olive paste is moved into a key stage known as malaxation. You can think of this as the flavor-development phase. The paste is pumped into long, horizontal troughs where it’s slowly and gently churned by paddles. This isn't about more crushing. Instead, this slow mixing encourages the countless microscopic oil droplets to bump into each other and merge into larger drops, which are much easier to separate later.

It’s a lot like a baker kneading dough. The constant, gentle motion develops the final product. For olive oil, the temperature and time spent in the malaxer are huge factors. They directly influence the final flavor and, just as importantly, the amount of healthy polyphenols that are preserved in the oil.

This infographic lays out the three main stages of modern olive oil extraction in a simple, clear flow.

As you can see, the journey is logical. First, you break down the fruit. Then, you prepare the paste. Finally, you separate the oil. Each step is built on the one before it.

The Decanter Centrifuge Takes Over

After the malaxation is complete, the paste is ready for the star of the show: the decanter centrifuge. This machine is the heart and soul of a modern mill. Picture a salad spinner, but amplify its power and precision a thousand times over. The olive paste gets pumped into a horizontal drum that spins at thousands of RPMs.

This intense rotation generates enormous centrifugal force, forcing the different parts of the paste to separate based on their weight. It’s simple physics, applied with incredible power. The components naturally sort themselves into distinct layers:

- Olive Pomace: The heaviest stuff—crushed pits, skins, and pulp solids—is flung against the outer wall of the drum.

- Vegetable Water: This is the water from the olives themselves. It's lighter than the solids but heavier than the oil, so it forms a middle layer.

- Olive Oil: The lightest of all, the precious oil, migrates to the very center of the spinning drum, where it’s continuously siphoned off.

This process happens in a sealed environment, protecting the oil from the prolonged air exposure and heat that were common with old presses. The result is a much fresher, more stable oil that lasts longer.

Two-Phase vs. Three-Phase Systems

Not all centrifuges are created equal. Mills today typically use one of two systems—two-phase or three-phase—and the choice makes a big difference for both the final product and the environment.

The three-phase decanter was the original standard. It works by adding a stream of warm water to the paste, which helps make the separation cleaner. As its name suggests, it spits out three things: oil, water, and solid pomace. It works well, but it uses a ton of water and creates a lot of liquid waste (the "vegetable water") that’s tricky to dispose of responsibly.

Because of those issues, many mills have switched to the more modern two-phase decanter. It’s often called an "ecological" system because it adds no extra water. It separates the paste into just two outputs: the oil and a single, wet pomace that contains all the solids and the olive’s natural water. This dramatically cuts down on water use and gets rid of the liquid waste problem. On top of that, many producers feel it creates a better oil with more polyphenols, since these healthy compounds aren’t getting washed away by added water.

Two-Phase vs. Three-Phase Centrifugation Compared

This table provides a quick look at how these two modern centrifuge systems stack up against each other, comparing their core functions and outputs.

| Feature | Two-Phase System | Three-Phase System |

|---|---|---|

| Water Usage | No additional water required, making it more eco-friendly. | Requires a significant amount of added water to aid separation. |

| Byproducts | Produces two outputs: oil and a single wet pomace. | Produces three outputs: oil, vegetable water, and a drier pomace. |

| Polyphenol Content | Generally results in oil with a higher concentration of healthy polyphenols. | Can lose some water-soluble polyphenols to the wastewater stream. |

| Environmental Impact | Lower impact due to reduced water use and no liquid waste. | Higher impact due to large water consumption and wastewater disposal. |

In the end, the move to centrifugation was a huge leap forward for olive oil extraction. It gives producers an incredible amount of control, allowing them to make a consistently high-quality product while also being better stewards of the environment and preserving those beautiful, delicate flavors that make extra virgin olive oil so special.

What Cold Extraction Really Means for Quality

You've probably seen "cold pressed" or "cold extraction" proudly displayed on high-end olive oil bottles. These aren't just marketing buzzwords; they're a signal of quality, a promise from the maker that they’ve put care into their craft. But what do they actually mean in a modern mill, where traditional presses are a rare sight?

It all comes down to one critical factor: temperature.

True “cold extraction” means the olive paste was kept below a very specific threshold—27°C (about 80.6°F)—during the entire malaxation and centrifugation process. For anyone serious about making authentic extra virgin olive oil, this isn't a guideline; it's a rule you simply don't break.

Think of it like brewing tea. If you scorch delicate green tea leaves with boiling water, you get a fast, strong brew, but it’s often bitter and harsh. You’ve burned off all the nuanced, aromatic notes. Use cooler water, however, and you gently coax out the complex flavors and fragrant aromas. Olive oil works exactly the same way.

The Science Behind Staying Cool

Why all the fuss about a few degrees? The answer is pure chemistry. The things we prize most in extra virgin olive oil—its vibrant, fruity aromas and its healthy polyphenols—are incredibly fragile. These are the compounds that create those wonderful green, peppery, and sometimes bitter notes that scream "freshness" and "quality."

These delicate molecules are extremely sensitive to heat. As soon as the olive paste creeps above that 27°C mark, they begin to break down and evaporate. What you're left with is an oil that's less flavorful, less fragrant, and frankly, less healthy. This presents every producer with a constant, critical choice.

A higher temperature can actually squeeze more oil out of the paste, which means a better yield. But this extra quantity comes at a steep cost: a major drop in quality. The oil loses its character, its antioxidant punch, and its soul.

The best producers know this all too well. They will always sacrifice a little bit of yield to protect the integrity of their oil. This means investing in temperature-controlled machinery and keeping a vigilant eye on the process, ensuring the paste never overheats—not even from the friction of its own mixing.

Flavor and Health on the Line

The effect of temperature isn't subtle. It’s the difference between an oil that bursts with life and one that just tastes oily. During the olive oil extraction process, here’s exactly what’s at stake:

- Polyphenols: These are the powerful antioxidants behind the peppery kick and pleasant bitterness in a great oil. They're also where most of the health benefits come from. Heat decimates them, meaning an oil extracted hot will have a far lower polyphenol count.

- Aromas: Those beautiful scents of fresh-cut grass, green almond, or artichoke? They come from volatile compounds that, like a fine perfume, simply float away when warmed up, leaving a much duller product behind.

- Oxidation: Heat speeds up oxidation, the chemical reaction that causes oils to go rancid. Extracting cool helps create a more stable oil that will stay fresh longer.

Ultimately, "cold extraction" is a promise. It tells you the producer chose quality over quantity, taking every step to preserve the raw, natural goodness of the olives. It’s your assurance that the bottle in your hand contains an oil that is not only delicious but also brimming with the very compounds that have made it a cornerstone of healthy living for thousands of years. When you choose a genuinely cold-extracted oil, you're choosing to taste the true, uncompromised essence of the olive.

Global Production and Its Biggest Challenges

The journey from a single olive to the golden oil in your kitchen is a story of incredible care. But to really grasp what's behind that bottle, we need to pull back from the individual mill and look at the bigger picture. It's a global marketplace shaped by massive agricultural forces, fierce competition, and one overwhelming factor: the climate.

The olive oil world has long been dominated by a handful of Mediterranean countries. Spain, in particular, is the industry's giant. Its output is so vast that a good or bad harvest in its Andalusian groves sends ripples across the globe, influencing the price and availability of olive oil on every continent.

But this system is anything but stable. Olive trees are notoriously sensitive to the weather, which makes the entire industry incredibly vulnerable to climatic shifts. A single, ill-timed frost in spring can mean the flowers never become fruit. A blistering summer heatwave or a long drought can shrivel the olives right on the branch, decimating both the amount of oil and its quality.

The Unpredictable Nature of Harvests

This sensitivity to climate creates wild swings in production from one year to the next. Take the forecasts for the 2024/2025 olive oil extraction season, for example. Global output is expected to bounce back, surpassing 3.1 million tons. This recovery is almost entirely thanks to Spain, which is projected to produce nearly 1.3 million tons—a staggering 52% jump from its previous, drought-ravaged season.

Meanwhile, Italy is facing the opposite problem, with its own production predicted to fall sharply after battling severe drought and heat. These numbers paint a clear picture of just how volatile the industry is. You can dig deeper into these production forecasts for 2024-2025 to see the full story.

This constant fluctuation creates a persistent state of uncertainty. One year, a country might enjoy a bumper crop and flood the market. The next, its harvest could be cut in half, causing shortages and price hikes felt by shoppers thousands of miles away. It’s a powerful reminder that the price you pay at the store is directly tied to the weather in a Spanish or Italian olive grove.

It's not just an economic puzzle; it’s a real agricultural battle that forces growers to constantly adapt. They're up against a host of climate-related threats that can make or break their entire year.

- Drought Stress: Lack of water is the most common enemy. It results in smaller olives that yield far less oil.

- Extreme Heat: Heatwaves, especially when the olives are developing, can literally cook the fruit on the tree, making high-quality oil impossible.

- Unseasonal Frost: A late spring frost can kill the delicate blossoms, meaning no fruit will grow at all.

- Erratic Rain: Too much rain at the wrong time can encourage fungal diseases and dilute the oil's precious flavor and quality.

Emerging Players and Shifting Landscapes

While traditional giants like Spain and Italy wrestle with these climate challenges, other regions are starting to make their move. Countries across North Africa, for instance, are becoming increasingly important players on the world stage.

Tunisia is a perfect example. Its production is forecasted to climb significantly, potentially hitting 325 thousand tons. This points to a bigger trend where new producers are capitalizing on favorable conditions just as historic leaders are facing setbacks.

This changing of the guard is creating a more dynamic—and complex—global market. The story is no longer just about Spain and Italy. Producers from Tunisia, Turkey, and even parts of the Americas are making their mark, introducing new flavor profiles and adding new competitive pressures.

For those of us who love good olive oil, this means more variety. But it also highlights the fragility of an agricultural system so deeply connected to our planet's changing climate. The future of olive oil extraction truly depends on how well all these producers, both old and new, can navigate these immense challenges.

How Experts Define Olive Oil Quality

So, you’ve gone through the entire, painstaking process of extracting olive oil. How do you know if you've produced a good oil, or a truly great one? It's not just a matter of taste. The official grading system is a rigorous, two-part evaluation that separates average oils from authentic extra virgin olive oil by combining hard science with highly trained human senses.

Think of it like this: an oil has to pass two major exams to earn the coveted "extra virgin" title. First, a lab test, and second, a taste test. It’s like a world-class athlete who not only needs to have incredible stats on paper (the chemical tests) but also has to perform flawlessly on the field (the sensory test).

The Chemical Fingerprint

The first stop is the laboratory. Here, technicians analyze the oil’s chemical makeup, looking for specific markers that tell the story of its quality and freshness. This isn't about finding additives; it's about checking the oil’s natural state to see how well it was made and how healthy the olives were to begin with.

A few key metrics give a crystal-clear picture of the oil's integrity:

- Free Fatty Acidity (FFA): This is the big one. FFA measures the breakdown of fats, a process that accelerates when olives are damaged, overripe, or left sitting around for too long before milling. A lower FFA indicates healthier fruit and prompt processing. For an oil to be called extra virgin, its FFA must be below 0.8%.

- Peroxide Value: This test checks for primary oxidation, giving a snapshot of the oil's initial freshness. If the peroxide value is high, it means the oil has already started to degrade, likely due to too much heat or air exposure during or after extraction.

- Polyphenol Count: While not always a required part of the official grading, this is a huge indicator of a top-tier oil. Polyphenols are powerful antioxidants that give high-quality oil its characteristic peppery kick and most of its incredible health benefits. A higher count usually means a more robust and longer-lasting oil.

An oil can pass all the chemical tests with flying colors and still not make the cut for extra virgin. The lab analysis simply confirms the oil is free from major flaws; it doesn’t guarantee it has the positive, delicious characteristics that make it exceptional.

The Art of Sensory Testing

Once an oil gets the green light from the lab, it moves on to the second, and arguably more difficult, challenge: organoleptic, or sensory, analysis. This is where the art of olive oil tasting truly meets science. A panel of professionally trained tasters evaluates the oil’s aroma and flavor in a highly controlled environment.

These experts are on the hunt for two things. First, they're looking for positive "fruity" characteristics—fresh, pleasant notes like green grass, tomato leaf, or even artichoke.

Second, and more critically, they are trained to detect any defects. Even the faintest hint of a flaw is grounds for immediate disqualification from the extra virgin category.

Common defects include:

- Rancid: The most common flaw, which happens when the oil is exposed to oxygen.

- Fusty: A fermented character that develops when olives are piled up and stored for too long.

- Musty: A moldy flavor that comes from fungus growing on the fruit before pressing.

Only an oil with zero defects and a detectable level of fruitiness can be legally labeled as extra virgin. This dual system is our best guarantee that when you pick up a bottle of real extra virgin olive oil, you’re getting a product that is both chemically pure and tastes exactly as it should—like the fresh, vibrant juice of perfectly grown olives.

Common Questions About Olive Oil Extraction

As you dive deeper into the world of olive oil, you're bound to have some questions. Getting to grips with the details of olive oil extraction really pulls back the curtain on the process, giving you a whole new appreciation for what's in the bottle. Let's tackle some of the most common curiosities.

Is Unfiltered Olive Oil Better?

It's not about being better, just different. Unfiltered oil, which you might see marketed as olio nuovo ("new oil"), still has tiny bits of olive fruit suspended in it. This is what gives it that cloudy look and a really bold, vibrant flavor that many olive oil lovers seek out.

The catch? Those little solids can eventually settle at the bottom and make the oil spoil faster. Filtered oil, by contrast, is crystal clear and will last much longer on your shelf with a more stable, consistent flavor. It all comes down to your personal preference and how quickly you think you'll get through the bottle.

What Happens to the Leftover Olive Paste?

That leftover solid mash of pits and pulp is called pomace, and it’s far too useful to just toss out. There's still a tiny bit of oil trapped inside, which can be pulled out using industrial methods like solvents and heat. The result is what's sold as olive pomace oil.

The final, dry pomace gets a second life, making the whole operation remarkably sustainable. It's often used as:

- Biofuel to help power the olive mill itself.

- Animal feed, adding nutrients to livestock diets.

- Natural fertilizer to enrich the soil back in the olive groves.

Can You Make Olive Oil at Home?

Technically, yes, you can. But honestly, getting anywhere near the quality of a commercially made extra virgin olive oil is incredibly tough. The biggest hurdles are crushing the olives into a perfectly smooth paste and then cleanly separating the oil from the water without a professional centrifuge.

Home presses usually can't generate the force needed for a decent extraction, and keeping the temperature just right during the malaxation phase is next to impossible without the right gear. You'll likely end up with a very small amount of oil that's a bit rough around the edges.

Why Is Extra Virgin Olive Oil So Expensive?

That price tag really comes down to the sheer amount of hands-on labor and meticulous care required from tree to bottle. Making world-class EVOO is a game of quality, not quantity. It starts with harvesting olives at their peak moment of ripeness—often when they're still young—which means less oil per olive but a huge payoff in flavor and aroma.

From there, the olives have to be rushed to the mill within hours and processed using sophisticated 'cold extraction' methods to keep all their fragile, healthy compounds intact. The final oil then has to pass rigorous chemical analysis and be judged by a professional tasting panel. This intense focus on getting every detail right is what makes a superior—and yes, more expensive—product.

Ready to explore the world of premium olive oil with confidence? At Learn Olive Oil, we provide expert guides, tasting notes, and recommendations to help you discover the best oils from around the globe. Start your journey and elevate your culinary experience today.

Leave a comment