Getting Your Timing Right For Peak Quality

Timing is everything when it comes to olive oil harvesting. The goal is to strike the perfect balance between maximizing the amount of oil you produce and achieving the best possible flavor. This requires a deep understanding of how ripeness affects the final product.

Reading the Signs of Ripeness

Experienced olive growers know that a calendar isn't enough. They carefully observe their trees for telltale signs. A key indicator is the color of the olives. As they ripen, the olives transform from green to a mix of green and purple, finally becoming a dark, almost black, purple. But color isn't the only factor.

A deep purple color might suggest higher oil content, but it doesn't guarantee the best flavor. Oil content can be accurately measured using portable devices. These tools provide crucial data for determining the optimal harvest time.

The Polyphenol-Yield Balancing Act

Harvesting early often produces olive oil with higher levels of polyphenols. These are powerful antioxidants linked to numerous health benefits and contribute to the peppery, pungent taste of high-quality extra virgin olive oil. The trade-off is a lower overall oil yield.

Waiting for the olives to ripen fully can boost oil production. This is good for quantity, but it can compromise flavor intensity and reduce the polyphenol content. Choosing the right harvest time means balancing quality and quantity.

Weather's Impact on Harvesting Decisions

Weather plays a significant role in olive harvesting. Too much rain can dilute the oil in the fruit, while extended dry periods can result in overripe olives. Keeping an eye on weather forecasts, both short-term and long-term, is essential.

A sudden downpour might require postponing the harvest. Conversely, a prolonged sunny spell can speed up ripening, requiring an earlier harvest than planned. Careful weather monitoring allows growers to make informed choices to protect their valuable crop.

Avoiding Costly Harvesting Mistakes

A common mistake is waiting too long to harvest. This leads to overripe olives and oil that lacks flavor and has a shorter shelf life. Another pitfall is improper handling after harvesting. Delays in processing can cause unwanted oxidation, damaging the oil's quality.

To avoid these issues, use efficient harvesting methods and get the olives to the mill quickly. This ensures the freshest possible product for oil extraction. Investing in proper storage also helps preserve olive quality until processing. By avoiding these common mistakes and following best practices, you can maximize the quality of your olive oil.

Traditional Methods That Still Outperform Modern Tech

While technological advancements in olive oil harvesting offer clear benefits, traditional methods remain essential, particularly for crafting high-quality extra virgin olive oil. These time-tested techniques, handed down through generations, emphasize careful fruit handling and maintaining the olive's integrity, which often results in oils with exceptional flavor profiles.

Hand-Picking: The Gold Standard

Hand-picking is the oldest olive harvesting method. It involves carefully plucking individual olives from the branches. This minimizes damage to both the fruit and the tree, preserving the olive's delicate flavors. Although labor-intensive, hand-picking allows for selective harvesting of only the ripest olives. This meticulous approach is vital for producing premium olive oil.

Traditional Tools Play a Key Role

Even with hand-picking, tools are necessary. Wooden rakes, resembling large combs, are gently employed to detach olives from the branches, mimicking the natural shedding process. These tools reduce bruising and preserve the oil's quality. This traditional method is particularly favored for delicate olive varietals where preserving subtle flavor nuances is crucial.

Ground Cloths and Ladder Techniques

Another important element of traditional olive harvesting is the use of ground cloths. These large nets or tarps are placed under the trees to catch the falling olives. This prevents the fruit from touching the ground, minimizing contamination and preserving quality. Furthermore, experienced harvesters utilize specific ladder placement strategies to reach all parts of the tree efficiently while minimizing stress on the branches.

Why Tradition Matters

For many producers, especially in regions like Italy, tradition is synonymous with quality. Italy is a major player in the olive oil industry, renowned for its exceptional extra virgin olive oils. In fact, projections for 2025 estimate Italy will produce approximately 500,000 metric tons of olive oil, securing its position as the second-largest global producer. Find more detailed statistics here. This commitment to traditional methods frequently yields superior oils that command premium prices. These producers firmly believe the gentle handling and careful selection inherent in traditional methods are fundamental to capturing the olive's true essence.

Balancing Labor and Quality

The main disadvantage of traditional olive harvesting is the labor involved. Hand-picking is significantly more time-consuming than mechanical methods, leading to higher labor costs, which can be a challenge, particularly for larger-scale producers. However, for smaller, quality-focused operations, the superior quality of the resulting oil justifies the increased labor investment.

Comparing Traditional and Modern Methods

| Feature | Traditional Methods | Modern Methods |

|---|---|---|

| Labor | High | Low |

| Cost | High | Lower |

| Fruit Integrity | Excellent | Can be lower depending on method |

| Oil Quality | Potentially higher, nuanced flavors | Can be very high, more efficient |

| Scalability | Limited | High |

This comparison illustrates the key differences between traditional and modern olive harvesting methods. While modern methods excel in efficiency and scalability, traditional approaches prioritize fruit integrity and have the potential to achieve superior quality. This is especially important for extra virgin olive oil, where delicate flavors and a high polyphenol content are highly valued. The ideal harvesting method depends on the producer's specific goals and available resources. Choosing the appropriate harvesting method is a critical decision that directly influences the final product's quality and market value.

Modern Equipment That Actually Pays For Itself

Modern technology offers olive growers exciting new ways to boost efficiency and potentially increase their yield. However, not all equipment guarantees a worthwhile return. This section examines key mechanical harvesting solutions, helping you identify those that offer true value.

Trunk Shakers: Efficiency and Adaptability

Trunk shakers clamp onto the tree trunk and vibrate, detaching the olives. This method is particularly efficient for larger operations, significantly reducing manual labor. Different shaker sizes and configurations cater to various tree sizes and orchard layouts.

However, the initial investment for a trunk shaker can be substantial. Careful evaluation is essential, weighing the long-term benefits against the upfront costs.

- Benefits: High efficiency, reduced labor costs, adaptable to a range of tree sizes.

- Drawbacks: High initial investment, potential for tree damage if used incorrectly.

Canopy Contact Systems: A Gentler Approach

Canopy contact systems, also called "shakers," use vibrating rakes or rods to detach olives. These systems offer a gentler touch, minimizing damage to trees and fruit. This is vital for maintaining long-term tree health and producing high-quality olive oil. They are also effective in orchards with dense canopies.

However, canopy contact systems can be slower than trunk shakers, especially with larger trees. This may affect overall harvesting time.

- Benefits: Gentle on trees and fruit, effective in dense canopies.

- Drawbacks: Can be slower than trunk shakers, potentially less efficient for large-scale operations.

Over-the-Row Harvesters: Peak Mechanization

For large-scale olive harvesting, over-the-row harvesters represent peak mechanization. These machines straddle tree rows, using shaking mechanisms to detach olives from entire rows at once.

They drastically reduce labor needs and harvest time, particularly in intensive orchards. However, the high purchase price and ongoing maintenance represent significant financial considerations.

- Benefits: Maximum efficiency, significant labor reduction, ideal for intensive orchards.

- Drawbacks: Very high initial investment, requires specialized training and maintenance.

Evaluating Equipment for Your Specific Needs

Choosing the right harvesting equipment requires careful consideration of your individual circumstances. Smaller groves focused on high-quality extra virgin olive oil may find trunk shakers or canopy contact systems suitable. Larger producers targeting high-volume output may find over-the-row harvesters more appropriate.

Considering the Hidden Costs: Maintenance

Manufacturers often emphasize the efficiency of their equipment, but understanding ongoing maintenance is critical. All mechanical harvesting equipment requires regular upkeep, including lubrication, repairs, and replacement parts. Factoring these expenses into your budget provides a realistic assessment of the true cost of ownership.

Operator Skill and the Learning Curve

Operating modern olive oil harvesting equipment effectively requires skill and training. Investing in proper operator training is crucial. This maximizes equipment efficiency, minimizes potential tree damage, and prevents costly mistakes, ultimately extending the lifespan of your equipment.

By carefully considering these factors – equipment type, maintenance costs, and operator training – growers can make informed decisions. Choosing equipment tailored to your specific needs ensures a genuine return on investment, maximizing harvest efficiency while maintaining the quality of your olive oil.

Learning From Global Production Powerhouses

Studying the olive oil harvesting methods of the world’s leading producers offers valuable insights. By understanding the diverse approaches used globally, growers can learn how to optimize their own operations. This knowledge is especially useful for adapting new techniques and understanding the balance between tradition and technology in olive oil production.

Mediterranean Precision vs. Industrial Scale

The Mediterranean region, the birthplace of olive cultivation, is known for its emphasis on precision and quality. Many producers, particularly in Italy and Greece, still use traditional hand-picking methods. These labor-intensive techniques protect the fruit and allow for selective harvesting of only the ripest olives. This meticulous process results in high-quality oils, often with rich and complex flavors.

However, in regions like Spain, where production is much larger, mechanical harvesting is more common. This method significantly boosts efficiency and lowers labor costs, crucial for meeting international demand. Spain's success shows that high-quality olive oil can be produced efficiently at scale. The global olive oil market is significantly impacted by these major producers. In fact, Spain is predicted to remain the top olive oil producer in 2025, with an estimated output of over 1.5 million metric tons. This substantial volume drives both domestic use and international trade, highlighting Spain's key role in the global market. Explore this topic further.

Regional Methods and Product Quality

The connection between regional harvesting methods and the final product's quality is intricate. While hand-picking is often linked with premium extra virgin olive oil, modern mechanical techniques can also yield high-quality oil when done correctly. For instance, some producers effectively combine traditional practices with modern technology to maximize both quality and efficiency. This demonstrates the versatility of olive oil harvesting and the potential for innovation.

Adapting Innovations and Cultural Influences

Observing the practices of leading global producers provides valuable lessons for growers of all sizes. Smaller producers can learn from the quality-focused approaches of Mediterranean growers, while larger operations can gain insights from the efficiency and scale of industrial producers. Furthermore, understanding how cultural traditions shape harvesting choices offers unique perspectives on balancing quality, efficiency, and sustainability.

To illustrate the various approaches, let's examine a comparison of major olive oil-producing countries. The following table shows their production volumes, harvesting methods, and quality characteristics.

Global Olive Oil Production Comparison

| Country | Annual Production (Metric Tons) | Primary Harvesting Method | Quality Focus |

|---|---|---|---|

| Spain | Over 1.5 million (projected 2025) | Mechanical | Efficiency, consistent quality |

| Italy | Varies, typically less than Spain | Mixed (Hand-picking/Mechanical) | Tradition, high-quality extra virgin |

| Greece | Varies, typically less than Spain | Mixed (Hand-picking/Mechanical) | Regional varieties, flavor profiles |

| Tunisia | Varies, significant producer | Mechanical | Price competitiveness |

| Turkey | Varies, growing producer | Mixed (Hand-picking/Mechanical) | Emerging market, diverse varietals |

This table highlights the varied approaches to olive oil harvesting, reflecting the influence of production scale, cultural practices, and market demands. Ultimately, the most effective method depends on the specific needs and objectives of each grower. By learning from global leaders, producers can improve their olive oil harvesting strategies and strive for continuous improvement.

Protecting Your Investment After The Harvest

The olive harvest is a significant milestone, but it's just the beginning of the journey towards producing high-quality olive oil. The post-harvest phase is critical, impacting the oil's flavor, aroma, and shelf life. Proper handling and storage immediately after harvesting can significantly influence the final product's market value.

The Science of Post-Harvest Handling

Harvested olives are delicate and prone to quality degradation. Oxidation, a chemical reaction occurring when the fruit flesh is exposed to air, poses a major threat. Oxidation can lead to off-flavors and unpleasant aromas, diminishing the oil's overall quality.

Temperature also plays a crucial role. Heat accelerates enzymatic activity within the olives, further degrading quality. Ideally, olives should be processed within 24 hours of harvest. This rapid turnaround helps preserve the oil's freshness and captures its delicate characteristics.

Storage Solutions That Preserve Quality

When immediate processing isn't possible, proper storage is essential. Perforated crates or bins allow air circulation, preventing heat and moisture buildup. Avoid storing olives in plastic bags or airtight containers, as these can trap moisture and promote fermentation, negatively impacting the oil's quality.

For larger operations, controlled-atmosphere storage offers a more advanced solution. These systems regulate temperature, humidity, and oxygen levels, creating an ideal environment for preserving olive quality before processing.

Transportation: Maintaining Fruit Integrity

Transportation from grove to mill also requires careful consideration. Rough handling and extended transport times can bruise the fruit, increasing oxidation risk and impacting oil quality.

Protective measures, such as using padded bins or containers with dividers, can minimize bruising during transport. Selecting a nearby mill can also reduce transport time and preserve olive freshness.

Temperature Management: Preventing Oxidation

Maintaining optimal temperature is vital throughout the post-harvest process. High temperatures contribute to oxidation and off-flavors. Keeping olives cool, preferably below 77°F (25°C), slows down enzymatic reactions and preserves quality.

Some producers utilize refrigerated trucks to maintain optimal temperatures during transport. While adding cost, this practice prioritizes quality and ensures a premium final product.

Timing Considerations for Maximizing Potential

The time between harvest and processing, often referred to as "lag time," should be minimized. The ideal timeframe is 24 hours, but operational constraints may make this challenging. However, minimizing lag time remains crucial for producing high-quality oil.

Strategies for minimizing lag time include coordinating harvest schedules with mill availability and, for larger operations, investing in on-site processing facilities.

Scaling Post-Harvest Practices

Post-harvest solutions vary depending on the operation's size. Smaller producers can prioritize careful handling, efficient transport, and rapid processing. Larger operations might benefit from investing in advanced technologies like controlled-atmosphere storage and dedicated transport logistics. Regardless of size, understanding and implementing best practices for post-harvest handling is essential for producing premium olive oil.

By adopting these strategies, olive growers can protect their investment and maximize the quality of their olive oil. Post-harvest handling is a crucial factor that significantly influences the final product's quality, flavor, and market value.

Choosing Your Harvesting Strategy With Confidence

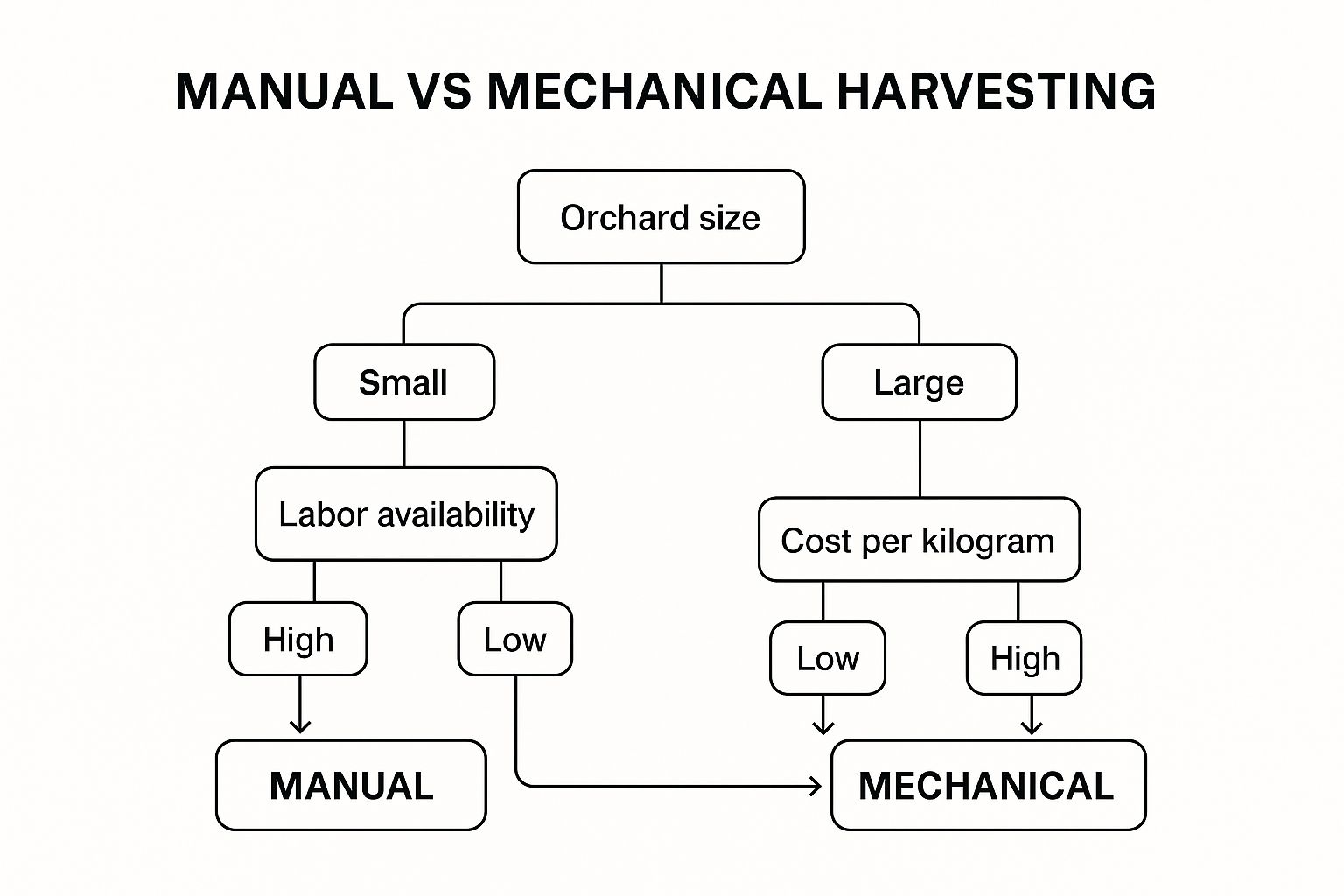

The infographic above provides a helpful decision tree for olive growers deciding between manual and mechanical harvesting. It considers key factors like orchard size, labor availability, and target cost per kilogram. Smaller orchards with available labor and a focus on minimizing costs often favor manual harvesting, as the infographic shows. Larger operations with limited labor and a higher acceptable cost per kilogram often find mechanical methods more suitable. The best strategy depends on the unique combination of these factors.

Matching Your Orchard to the Right Method

Choosing the best olive oil harvesting strategy requires careful consideration of your orchard's specific characteristics. There's no single solution that fits every situation. For example, a small, family-run orchard with terraced terrain might be ideal for manual harvesting. This allows for careful handling and selective picking of the olives.

However, a larger commercial orchard on flat land might benefit from mechanical harvesting methods, such as trunk shakers or over-the-row harvesters. These methods offer greater efficiency and reduce labor costs, an important factor for larger-scale operations.

Quality Objectives and Your Harvesting Choice

Your desired oil quality also plays a role in selecting your harvesting strategy. Hand-picking might be the preferred method for producing premium extra virgin olive oil with high polyphenol content and intense flavor. This allows for selecting only the ripest olives, preserving their delicate qualities.

Mechanical harvesting provides an efficient solution for producers focused on larger volumes and consistent quality. While less selective, this approach can still yield high-quality oil when combined with proper post-harvest practices.

Budget Realities and Cost-Benefit Analysis

Cost is a critical factor in olive oil harvesting. Manual harvesting involves higher labor costs but lower equipment expenses. Mechanical harvesting requires a significant initial investment in machinery but reduces ongoing labor costs.

A thorough cost-benefit analysis is essential. This means assessing upfront equipment costs, ongoing maintenance, labor costs, and potential yield increases. This analysis helps determine the method that best aligns with your budget and long-term financial goals.

Let's take a look at the following table to compare the different harvesting methods:

Harvesting Methods Comparison Matrix

Detailed comparison of different olive harvesting techniques showing efficiency, quality impact, costs, and suitable applications

| Method | Efficiency Rate | Quality Impact | Cost Level | Best Use Case |

|---|---|---|---|---|

| Manual Harvesting | Lower | Highest Potential | High Labor, Low Equipment | Small orchards, high-quality oil |

| Mechanical Harvesting (Trunk Shakers) | Higher | Potential for bruising | Moderate Labor, High Equipment | Larger orchards, moderate quality |

| Mechanical Harvesting (Over-the-Row) | Highest | Highest risk of bruising | Low Labor, High Equipment | Large-scale operations, high efficiency |

As the table shows, each harvesting method presents a trade-off between efficiency, quality, and cost. Manual methods excel in quality but are less efficient. Mechanical methods maximize efficiency but carry risks to fruit quality.

Planning for Changing Conditions

Olive oil harvesting can be unpredictable. Weather changes, labor shortages, and equipment breakdowns can disrupt the process. A backup plan is essential. If you rely primarily on mechanical harvesting, a network of hand-pickers can be crucial if equipment fails.

Flexibility in your harvesting schedule helps you adapt to changing weather conditions. This could involve adjusting your harvest window or temporarily switching methods to minimize potential quality loss.

Hybrid Approaches: Combining the Best of Both Worlds

Many olive growers are now using hybrid approaches, combining manual and mechanical techniques. This allows them to leverage the advantages of both methods. They might use mechanical harvesters for most of the harvest and hand-pick in areas with difficult terrain or where they prioritize the highest quality. This targeted approach maximizes efficiency while ensuring premium quality for specific parts of their production. By strategically combining manual and mechanical methods, producers can tailor their strategies to their needs and desired results.

Key Takeaways

This section offers practical strategies for successful olive oil harvesting, based on expert knowledge and proven methods. Whether you're a beginner or a seasoned olive grower, these takeaways provide actionable insights to enhance your operation. We'll explore decision-making frameworks for choosing the right method, quality checkpoints, and benchmarks for operations of all sizes. Each takeaway highlights measurable progress and clear indicators of success, setting realistic expectations as you refine your harvesting process.

Timing Your Harvest for Optimal Results

Timing is everything in olive oil harvesting. The ideal harvest time strikes a balance between maximum oil yield and peak fruit quality. Visual cues, such as changes in olive color, combined with oil content measurements, offer valuable data. Harvesting early yields oil rich in beneficial polyphenols, resulting in a pungent flavor and significant health benefits. Waiting longer might increase oil quantity, but potentially at the expense of flavor and antioxidant levels. Keeping a close eye on weather patterns is crucial. Adjusting harvest schedules to account for rainfall and temperature fluctuations helps prevent losses and preserves the quality of the olives.

Traditional Techniques and Their Continued Relevance

Traditional harvesting methods, like hand-picking, prioritize the integrity of the olive fruit. This careful approach minimizes damage and allows for selective harvesting of perfectly ripe olives. Using wooden rakes and ground cloths further protects the fruit, contributing to the production of premium-quality oil. However, these traditional methods are labor-intensive, which can be a constraint for larger producers. They are often the preferred choice for smaller, quality-focused operations aiming for high-quality extra virgin olive oil.

Modern Equipment and Return on Investment

Modern technologies offer significant gains in harvesting efficiency. Trunk shakers are an effective harvesting solution for larger operations, while canopy contact systems provide a gentler approach, minimizing damage to the olive trees. Over-the-row harvesters maximize efficiency in large-scale orchards. However, investing in these technologies requires a thorough cost-benefit analysis, considering initial costs, ongoing maintenance, and operator training. This careful evaluation ensures a positive return on investment.

Global Perspectives on Olive Oil Harvesting

Learning from leading olive oil producers around the world can offer valuable insights. The Mediterranean region, with its long-standing tradition of precision and quality, often favors hand-picking methods. In contrast, large-scale producers, such as those in Spain, often utilize mechanized harvesting to maximize efficiency. Understanding the global landscape of olive oil harvesting allows growers to adapt successful strategies to their specific circumstances.

Securing Quality Post-Harvest

Post-harvest handling is essential for preserving the quality of the olive oil. Minimizing the lag time – the time between harvest and processing – is critical for limiting oxidation. Proper storage in perforated containers prevents moisture buildup and helps maintain quality. Controlled temperatures and careful transport further protect the harvested olives. Adhering to post-harvest best practices ensures premium oil quality, regardless of the size of the operation.

Choosing the Right Harvesting Strategy

The optimal harvesting method depends on a variety of factors:

- Orchard size and terrain: Smaller, terraced orchards are often well-suited to manual harvesting, while larger, flatter orchards may benefit from mechanical solutions.

- Quality goals: Hand-picking is generally preferred for premium extra virgin olive oil production, while mechanical harvesting is better suited for high-volume production.

- Budget considerations: Carefully analyze the costs associated with equipment, labor, maintenance, and projected yield increases for each harvesting method.

Developing hybrid strategies that combine manual and mechanical techniques offers flexibility and can maximize both quality and efficiency. It’s also wise to have contingency plans in place for unexpected events, such as adverse weather conditions or equipment malfunctions.

Key Indicators of Success

Ultimately, successful olive oil harvesting is measured by several key indicators:

- Oil yield: Achieving target production levels within the optimal harvest window.

- Oil quality: Meeting established quality standards for acidity, peroxide value, and sensory characteristics.

- Efficiency: Optimizing labor and equipment utilization to minimize costs and maximize productivity.

- Sustainability: Implementing environmentally responsible practices to maintain orchard health and minimize resource use.

By focusing on these indicators, growers can effectively track their progress, adapt their strategies, and continuously improve their olive oil harvesting practices.

Ready to learn more about olive oil? Visit Learn Olive Oil to explore everything from selecting the best oils to understanding their health benefits and culinary uses.

Leave a comment